What is Rubber Repair Glue - Global Market?

Rubber repair glue is a specialized adhesive used globally for fixing and maintaining rubber products. This glue is essential in industries where rubber components are frequently used and need repair due to wear and tear. The global market for rubber repair glue is driven by the increasing demand for durable and efficient repair solutions in various sectors such as automotive, mining, and manufacturing. This type of glue is formulated to provide strong bonding and flexibility, ensuring that repaired rubber parts can withstand stress and environmental factors. The market is characterized by a variety of products, each designed to meet specific repair needs, from small household items to large industrial equipment. As industries continue to seek cost-effective maintenance solutions, the demand for rubber repair glue is expected to grow, making it a vital component in prolonging the life of rubber products and reducing waste. The market's expansion is also fueled by technological advancements that enhance the adhesive properties and application methods of rubber repair glue, making it more accessible and efficient for users worldwide.

Hot Bond, Cold Bond in the Rubber Repair Glue - Global Market:

Hot bond and cold bond are two primary methods used in the application of rubber repair glue, each with distinct characteristics and applications in the global market. Hot bonding involves the use of heat to activate the adhesive properties of the glue, creating a strong and durable bond between rubber surfaces. This method is often preferred in industrial settings where the repaired rubber components are subjected to high stress and temperature variations. The heat activation process ensures that the glue penetrates deeply into the rubber material, providing a robust and long-lasting repair. Hot bond adhesives are typically used in environments where the repaired rubber parts need to withstand extreme conditions, such as in mining or heavy machinery operations. On the other hand, cold bonding does not require heat for activation, making it a more convenient and versatile option for many applications. Cold bond adhesives are designed to cure at room temperature, allowing for easier application and faster repair times. This method is particularly useful in situations where heat application is impractical or could damage the rubber material. Cold bonding is often used in the repair of conveyor belts, pipes, and other rubber components that require quick and efficient maintenance. The choice between hot bond and cold bond methods depends largely on the specific requirements of the repair job, including the type of rubber material, the environmental conditions, and the desired strength of the bond. Both methods have their advantages and limitations, and the global market for rubber repair glue continues to innovate and improve these technologies to meet the diverse needs of industries worldwide. As the demand for reliable and efficient rubber repair solutions grows, manufacturers are investing in research and development to enhance the performance and application of both hot bond and cold bond adhesives. This includes the development of new formulations that offer improved adhesion, flexibility, and resistance to environmental factors. Additionally, advancements in application techniques, such as automated dispensing systems and portable repair kits, are making it easier for users to apply rubber repair glue effectively and efficiently. The global market for rubber repair glue is also influenced by regulatory standards and environmental considerations, prompting manufacturers to develop eco-friendly adhesives that minimize the impact on the environment. As industries continue to prioritize sustainability and cost-effectiveness, the demand for innovative rubber repair solutions is expected to drive the growth of the hot bond and cold bond segments in the global market.

Conveyor Belts, Tanks and Vessels, Pipes and Fittings, Others in the Rubber Repair Glue - Global Market:

Rubber repair glue plays a crucial role in the maintenance and repair of various industrial components, including conveyor belts, tanks and vessels, pipes and fittings, and other rubber-based products. In the case of conveyor belts, rubber repair glue is used to fix tears, holes, and other damages that occur due to continuous use and heavy loads. The adhesive properties of the glue ensure that the repaired sections of the conveyor belt can withstand the stress and friction of daily operations, thereby extending the lifespan of the equipment and reducing downtime. In tanks and vessels, rubber repair glue is used to seal leaks and reinforce weak areas, preventing the escape of liquids and gases. This is particularly important in industries such as chemical processing and oil and gas, where the integrity of tanks and vessels is critical to safety and efficiency. The glue provides a flexible and durable seal that can adapt to the expansion and contraction of the rubber material, ensuring a long-lasting repair. For pipes and fittings, rubber repair glue is used to fix leaks and cracks that can lead to costly water loss and damage. The adhesive properties of the glue allow it to bond effectively with the rubber material, creating a watertight seal that prevents further leakage. This is especially important in plumbing and irrigation systems, where the reliability of pipes and fittings is essential to maintaining efficient operations. In addition to these specific applications, rubber repair glue is also used in a variety of other areas, including automotive repairs, footwear manufacturing, and household maintenance. The versatility and effectiveness of rubber repair glue make it an indispensable tool for industries and consumers alike, providing a cost-effective solution for repairing and maintaining rubber products. As the demand for durable and efficient repair solutions continues to grow, the global market for rubber repair glue is expected to expand, driven by advancements in adhesive technology and the increasing need for sustainable maintenance practices.

Rubber Repair Glue - Global Market Outlook:

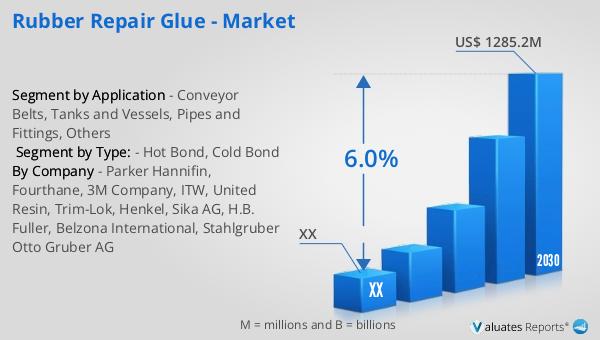

The global market for rubber repair glue was valued at approximately $856 million in 2023, and it is projected to grow to a revised size of $1,285.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.0% during the forecast period from 2024 to 2030. This growth is largely driven by the increasing demand for chemical solutions that enhance the durability and longevity of rubber products. The chemical composition of rubber repair glue is a significant factor in its effectiveness, as it determines the adhesive's ability to bond with rubber materials and withstand environmental stressors. As industries continue to seek cost-effective and reliable repair solutions, the demand for high-quality rubber repair glue is expected to rise. This market growth is also supported by technological advancements that improve the adhesive properties and application methods of rubber repair glue, making it more accessible and efficient for users worldwide. Additionally, the growing emphasis on sustainability and environmental responsibility is prompting manufacturers to develop eco-friendly adhesives that minimize the impact on the environment. As a result, the global market for rubber repair glue is poised for significant expansion, driven by the increasing need for durable and efficient repair solutions across various industries.

| Report Metric | Details |

| Report Name | Rubber Repair Glue - Market |

| Forecasted market size in 2030 | US$ 1285.2 million |

| CAGR | 6.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Parker Hannifin, Fourthane, 3M Company, ITW, United Resin, Trim-Lok, Henkel, Sika AG, H.B. Fuller, Belzona International, Stahlgruber Otto Gruber AG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |