What is Rocker Bioreactor - Global Market?

Rocker bioreactors are specialized devices used in the cultivation of cells and microorganisms, playing a crucial role in various biotechnological applications. These bioreactors are designed to provide a controlled environment for the growth and maintenance of biological cultures, offering a gentle rocking motion that ensures even distribution of nutrients and gases throughout the culture medium. This motion mimics the natural conditions that cells experience in their native environments, promoting optimal growth and productivity. The global market for rocker bioreactors is driven by the increasing demand for biopharmaceuticals, advancements in cell culture techniques, and the need for scalable and efficient bioprocessing solutions. These bioreactors are widely used in research and development, as well as in the production of vaccines, monoclonal antibodies, and other biologics. With the growing emphasis on personalized medicine and regenerative therapies, the demand for rocker bioreactors is expected to rise, as they offer a versatile and cost-effective solution for small to large-scale cell culture operations. The market is characterized by a diverse range of products, catering to different volume requirements and application needs, making it a dynamic and evolving sector in the biotechnology industry.

5L-20L, 20L-200L, 200L-1500L, Above 1500L in the Rocker Bioreactor - Global Market:

Rocker bioreactors are available in various sizes to accommodate different scales of production and research needs. The 5L-20L range is typically used for small-scale laboratory experiments and pilot studies. These bioreactors are ideal for initial feasibility studies, process optimization, and small-batch production. They offer flexibility and ease of use, making them suitable for academic research and early-stage biopharmaceutical development. The 20L-200L range is designed for medium-scale production and process development. These bioreactors are often used in R&D organizations and contract manufacturing organizations (CMOs) for process validation and scale-up studies. They provide a balance between capacity and operational efficiency, allowing for the production of larger batches while maintaining control over critical process parameters. The 200L-1500L range is geared towards large-scale production and commercial manufacturing. These bioreactors are used in biopharmaceutical industries for the production of therapeutic proteins, vaccines, and other biologics. They offer high throughput and scalability, enabling manufacturers to meet the growing demand for biopharmaceutical products. The above 1500L range represents the largest scale of rocker bioreactors, used for industrial-scale production. These bioreactors are employed in large biomanufacturing facilities for the mass production of biologics, providing the capacity to produce thousands of liters of product in a single batch. The choice of bioreactor size depends on the specific requirements of the production process, including the type of cells being cultured, the desired product yield, and the available infrastructure. Each size category offers unique advantages and challenges, requiring careful consideration and planning to ensure successful implementation and operation. The global market for rocker bioreactors is characterized by a wide range of products and technologies, catering to the diverse needs of the biotechnology and pharmaceutical industries. As the demand for biopharmaceuticals continues to grow, the market for rocker bioreactors is expected to expand, driven by advancements in cell culture techniques and the increasing adoption of single-use technologies. The versatility and scalability of rocker bioreactors make them an essential tool in the development and production of biologics, supporting the growth and innovation of the biotechnology industry.

Biopharmaceutical Industries, R&D Organizations, CMOs (Contract Manufacturing Organizations) in the Rocker Bioreactor - Global Market:

Rocker bioreactors play a significant role in the biopharmaceutical industry, research and development organizations, and contract manufacturing organizations (CMOs). In the biopharmaceutical industry, rocker bioreactors are used for the production of a wide range of biologics, including monoclonal antibodies, vaccines, and therapeutic proteins. They provide a controlled environment for cell culture, ensuring optimal growth conditions and high product yield. The gentle rocking motion of these bioreactors promotes even distribution of nutrients and gases, enhancing cell viability and productivity. This makes them an ideal choice for the production of high-quality biopharmaceutical products. In research and development organizations, rocker bioreactors are used for process development, optimization, and scale-up studies. They offer flexibility and ease of use, allowing researchers to conduct experiments and gather data on various cell culture processes. This information is crucial for the development of new biopharmaceutical products and the improvement of existing processes. Rocker bioreactors are also used in CMOs for contract manufacturing services. They provide a scalable and cost-effective solution for the production of biologics, enabling CMOs to meet the diverse needs of their clients. The versatility of rocker bioreactors allows CMOs to offer a wide range of services, from small-scale production to large-scale manufacturing. This flexibility is essential for meeting the growing demand for biopharmaceutical products and supporting the development of new therapies. The global market for rocker bioreactors is driven by the increasing demand for biopharmaceuticals, advancements in cell culture techniques, and the need for scalable and efficient bioprocessing solutions. As the biopharmaceutical industry continues to grow, the demand for rocker bioreactors is expected to rise, supporting the development and production of innovative therapies and biologics.

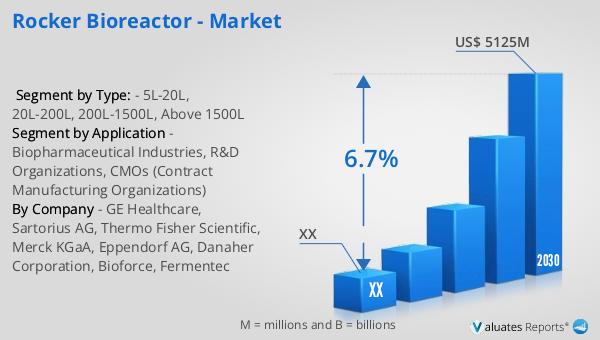

Rocker Bioreactor - Global Market Outlook:

The global market for rocker bioreactors was valued at approximately $3,185 million in 2023. This market is projected to grow significantly, reaching an estimated size of $5,125 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.7% during the forecast period from 2024 to 2030. This upward trend reflects the increasing demand for efficient and scalable bioprocessing solutions in the biotechnology and pharmaceutical industries. The growth of the rocker bioreactor market is driven by several factors, including advancements in cell culture techniques, the rising demand for biopharmaceuticals, and the increasing adoption of single-use technologies. These bioreactors offer a versatile and cost-effective solution for small to large-scale cell culture operations, making them an essential tool in the development and production of biologics. The market is characterized by a diverse range of products, catering to different volume requirements and application needs. As the demand for biopharmaceuticals continues to grow, the market for rocker bioreactors is expected to expand, supporting the growth and innovation of the biotechnology industry. The versatility and scalability of rocker bioreactors make them a valuable asset in the development and production of innovative therapies and biologics, contributing to the overall growth of the market.

| Report Metric | Details |

| Report Name | Rocker Bioreactor - Market |

| Forecasted market size in 2030 | US$ 5125 million |

| CAGR | 6.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | GE Healthcare, Sartorius AG, Thermo Fisher Scientific, Merck KGaA, Eppendorf AG, Danaher Corporation, Bioforce, Fermentec |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |