What is Railway Steel Rails - Global Market?

Railway steel rails are a crucial component of the global transportation infrastructure, serving as the backbone for trains that carry passengers and freight across vast distances. These steel rails are designed to withstand immense pressure and weight, ensuring the safe and efficient movement of trains. The global market for railway steel rails encompasses the production, distribution, and sale of these essential components. It involves a complex supply chain that includes raw material extraction, steel manufacturing, rail production, and distribution to various regions worldwide. The demand for railway steel rails is driven by the expansion of rail networks, modernization of existing infrastructure, and the increasing need for efficient and sustainable transportation solutions. As countries invest in their rail systems to reduce congestion, lower carbon emissions, and enhance connectivity, the market for railway steel rails continues to grow. This growth is supported by technological advancements in rail manufacturing, which improve the durability and performance of steel rails, making them more cost-effective and reliable. The global market for railway steel rails is a dynamic and evolving sector, reflecting the broader trends in transportation and infrastructure development.

Heavy Rail, Light Rail in the Railway Steel Rails - Global Market:

Heavy rail and light rail are two distinct segments within the railway steel rails market, each serving different purposes and catering to various transportation needs. Heavy rail, often associated with traditional train systems, is designed for long-distance travel and high-capacity freight transport. These rails are robust and capable of supporting the weight of large, powerful locomotives and long train cars. Heavy rail systems are typically used for intercity travel, connecting major urban centers and facilitating the movement of goods across regions. The construction of heavy rail systems requires significant investment in infrastructure, including the laying of durable steel rails that can withstand the stresses of high-speed and heavy-load operations. On the other hand, light rail systems are designed for shorter distances and are often used in urban environments to provide efficient public transportation. Light rail vehicles are generally smaller and lighter than heavy rail trains, making them suitable for navigating city streets and densely populated areas. The steel rails used in light rail systems are engineered to accommodate frequent stops and starts, as well as the tight curves and gradients commonly found in urban settings. Light rail systems are an integral part of public transit networks, offering a sustainable and cost-effective alternative to road-based transportation. Both heavy rail and light rail systems contribute to the overall efficiency and sustainability of transportation networks, reducing reliance on fossil fuels and minimizing traffic congestion. The global market for railway steel rails must cater to the specific requirements of both heavy and light rail systems, ensuring that the rails produced meet the necessary standards for safety, durability, and performance. As urbanization continues to rise and the demand for efficient transportation solutions grows, the market for both heavy and light rail systems is expected to expand, driving further innovation and investment in railway steel rail technology.

Conventional Rail, High-speed Rail, Metro Rail, Others in the Railway Steel Rails - Global Market:

Railway steel rails play a vital role in various types of rail systems, including conventional rail, high-speed rail, metro rail, and others. Conventional rail systems, which have been in operation for over a century, rely on steel rails to provide a stable and reliable track for trains. These systems are used for both passenger and freight transport, connecting cities and regions with a network of tracks that span vast distances. The durability and strength of steel rails are essential for supporting the heavy loads and high speeds associated with conventional rail operations. High-speed rail systems, which have gained popularity in recent decades, require specially designed steel rails that can accommodate the extreme speeds of modern trains. These rails are engineered to minimize friction and vibration, ensuring a smooth and safe ride for passengers traveling at speeds exceeding 300 kilometers per hour. The precision and quality of steel rails used in high-speed rail systems are critical to maintaining the safety and efficiency of these advanced transportation networks. Metro rail systems, commonly found in urban areas, utilize steel rails to provide efficient and reliable public transportation. These systems are designed to handle high passenger volumes, with trains running frequently and stopping at numerous stations throughout a city. The steel rails used in metro systems must be able to withstand the constant wear and tear of daily operations, as well as the unique challenges posed by urban environments, such as tight curves and steep gradients. In addition to these primary rail systems, steel rails are also used in other applications, such as industrial railways and specialized transport systems. These niche markets require customized steel rails that meet specific performance and safety standards, further highlighting the versatility and importance of steel rails in the global transportation landscape. As the demand for efficient and sustainable transportation solutions continues to grow, the usage of railway steel rails in various applications is expected to increase, driving further innovation and development in this critical industry.

Railway Steel Rails - Global Market Outlook:

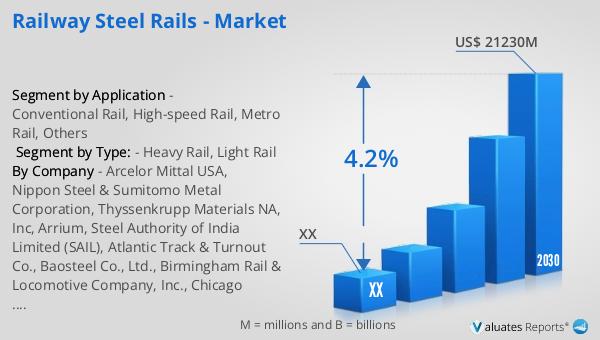

The global market for railway steel rails was valued at approximately $15.7 billion in 2023. This market is projected to grow significantly, reaching an estimated value of $21.23 billion by 2030. This growth represents a compound annual growth rate (CAGR) of 4.2% over the forecast period from 2024 to 2030. The expansion of the railway steel rails market is driven by several factors, including the increasing demand for efficient and sustainable transportation solutions, the modernization of existing rail infrastructure, and the expansion of rail networks in emerging economies. As countries invest in their rail systems to reduce congestion, lower carbon emissions, and enhance connectivity, the market for railway steel rails continues to grow. This growth is supported by technological advancements in rail manufacturing, which improve the durability and performance of steel rails, making them more cost-effective and reliable. The global market for railway steel rails is a dynamic and evolving sector, reflecting the broader trends in transportation and infrastructure development. As the demand for efficient and sustainable transportation solutions continues to grow, the usage of railway steel rails in various applications is expected to increase, driving further innovation and development in this critical industry.

| Report Metric | Details |

| Report Name | Railway Steel Rails - Market |

| Forecasted market size in 2030 | US$ 21230 million |

| CAGR | 4.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Arcelor Mittal USA, Nippon Steel & Sumitomo Metal Corporation, Thyssenkrupp Materials NA, Inc, Arrium, Steel Authority of India Limited (SAIL), Atlantic Track & Turnout Co., Baosteel Co., Ltd., Birmingham Rail & Locomotive Company, Inc., Chicago Heights Steel, Voestalpine Railway Systems, Evraz Oregon Steel Mills, Inc., AGICO, Kardemir A. S., KIMES Steel & Rail, Inc., Metinvest Holding, LLC, Posco, Rapid Rail Limited, Shandong China Coal Industrial & Mining Supplies Group, Vossloh AG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |