What is Quenching Inductor - Global Market?

Quenching inductors are specialized components used in various industrial applications to control and stabilize electrical currents. These inductors are crucial in processes that require precise heat management, such as induction heating and metal treatment. The global market for quenching inductors is driven by the increasing demand for efficient and reliable heating solutions across various industries. As industries continue to modernize and seek energy-efficient solutions, the demand for quenching inductors is expected to grow. These components are essential in ensuring that electrical systems operate smoothly, preventing overheating and potential damage to equipment. The market is characterized by a diverse range of products, catering to different industrial needs and specifications. Manufacturers are continuously innovating to improve the performance and efficiency of quenching inductors, making them more adaptable to the evolving needs of the global market. As a result, the quenching inductor market is poised for steady growth, driven by technological advancements and the increasing adoption of energy-efficient practices in industrial processes.

High Frequency Hardening Inductor, Intermediate Frequency Quenching Inductor in the Quenching Inductor - Global Market:

High-frequency hardening inductors and intermediate frequency quenching inductors are integral components in the quenching inductor market, each serving distinct purposes in industrial applications. High-frequency hardening inductors are primarily used in processes that require rapid heating and cooling cycles, such as surface hardening of metals. These inductors operate at high frequencies, allowing for precise control over the heating process, which is essential for achieving the desired material properties. The ability to quickly heat and cool materials makes high-frequency hardening inductors ideal for applications where surface hardness and wear resistance are critical. On the other hand, intermediate frequency quenching inductors are used in applications that require a balance between heating speed and depth of penetration. These inductors operate at lower frequencies compared to high-frequency inductors, providing a more uniform heating effect that penetrates deeper into the material. This makes them suitable for applications where both surface and core properties of the material need to be modified. The global market for these inductors is driven by the increasing demand for advanced manufacturing processes that require precise control over material properties. Industries such as automotive, aerospace, and heavy machinery are major consumers of these inductors, as they seek to improve the performance and durability of their products. The market is characterized by a wide range of products, each designed to meet specific industrial needs. Manufacturers are focusing on developing inductors that offer improved efficiency, reliability, and adaptability to different industrial environments. As industries continue to evolve and adopt new technologies, the demand for high-frequency hardening inductors and intermediate frequency quenching inductors is expected to grow. This growth is further supported by the increasing emphasis on energy efficiency and sustainability in industrial processes, as these inductors play a crucial role in reducing energy consumption and minimizing environmental impact. The market is also witnessing increased competition among manufacturers, leading to continuous innovation and improvement in product offerings. As a result, the global market for high-frequency hardening inductors and intermediate frequency quenching inductors is poised for steady growth, driven by technological advancements and the increasing adoption of advanced manufacturing processes.

Heating, Heat Treatment, Welding, Annealing, Others in the Quenching Inductor - Global Market:

Quenching inductors play a vital role in various industrial applications, particularly in heating, heat treatment, welding, annealing, and other processes. In heating applications, quenching inductors are used to generate precise and controlled heat, which is essential for processes such as metal melting and forging. The ability to control the heating process allows for improved efficiency and reduced energy consumption, making quenching inductors an essential component in modern industrial heating systems. In heat treatment applications, quenching inductors are used to alter the physical and mechanical properties of materials, such as hardness and strength. By precisely controlling the heating and cooling cycles, quenching inductors enable manufacturers to achieve the desired material properties, improving the performance and durability of their products. In welding applications, quenching inductors are used to control the heat input during the welding process, ensuring strong and reliable welds. The ability to precisely control the heat input is crucial in preventing defects such as cracks and distortions, which can compromise the integrity of the welded joint. In annealing applications, quenching inductors are used to relieve internal stresses and improve the ductility of materials. By carefully controlling the heating and cooling cycles, quenching inductors enable manufacturers to achieve the desired material properties, improving the performance and reliability of their products. In addition to these applications, quenching inductors are also used in various other industrial processes, such as brazing, soldering, and curing. The versatility and adaptability of quenching inductors make them an essential component in modern industrial processes, as they enable manufacturers to achieve precise control over the heating process, improving efficiency and reducing energy consumption. As industries continue to evolve and adopt new technologies, the demand for quenching inductors is expected to grow, driven by the increasing emphasis on energy efficiency and sustainability in industrial processes. The global market for quenching inductors is characterized by a diverse range of products, each designed to meet specific industrial needs. Manufacturers are continuously innovating to improve the performance and efficiency of quenching inductors, making them more adaptable to the evolving needs of the global market. As a result, the quenching inductor market is poised for steady growth, driven by technological advancements and the increasing adoption of energy-efficient practices in industrial processes.

Quenching Inductor - Global Market Outlook:

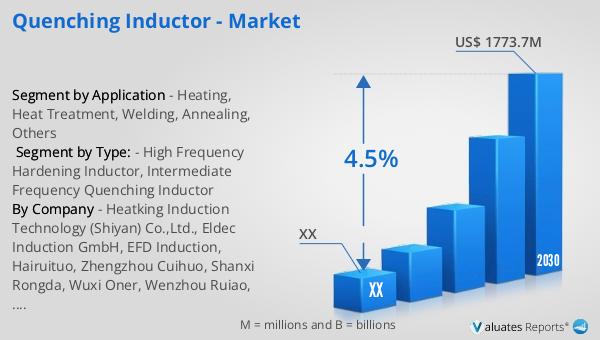

The global market for quenching inductors was valued at approximately $1,351 million in 2023, with projections indicating a growth to around $1,773.7 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030. This market expansion reflects the increasing demand for efficient and reliable heating solutions across various industries. In parallel, the construction machinery sector has also seen significant growth, particularly in Europe and the United States. In 2021, sales of construction machinery in Europe increased by 24%, highlighting a robust recovery and expansion in the sector. By 2022, the revenue from construction machinery in Europe reached approximately $22 billion, while the U.S. market reported sales of about $36 billion in the same year. This growth in construction machinery sales underscores the broader industrial demand for advanced and efficient equipment, which in turn drives the need for components like quenching inductors. As industries continue to modernize and seek energy-efficient solutions, the demand for quenching inductors is expected to grow, supported by technological advancements and the increasing adoption of energy-efficient practices in industrial processes.

| Report Metric | Details |

| Report Name | Quenching Inductor - Market |

| Forecasted market size in 2030 | US$ 1773.7 million |

| CAGR | 4.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Heatking Induction Technology (Shiyan) Co.,Ltd., Eldec Induction GmbH, EFD Induction, Hairuituo, Zhengzhou Cuihuo, Shanxi Rongda, Wuxi Oner, Wenzhou Ruiao, Nippon Avionics Co.,Ltd., Satra International, Shenzhen Shuangping, Baoding Sifang Sanyi Electric, Jinlai Electromechanical, Taizhou Hongri, HLQ Induction Equipment, Tianjin Tiangao, Zhangjiagang Jinda |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |