What is Processed Meat Emulsifier - Global Market?

Processed meat emulsifiers are crucial components in the global food industry, playing a significant role in enhancing the texture, stability, and shelf life of various meat products. These emulsifiers are substances that help blend ingredients that typically do not mix well, such as oil and water, ensuring a uniform and consistent product. In the context of processed meats, emulsifiers are used to improve the quality and appeal of products like sausages, beef, and pork. They help in binding water and fat, preventing separation, and maintaining the desired texture and flavor. The global market for processed meat emulsifiers is driven by the increasing demand for convenience foods and the growing awareness of food quality and safety. As consumers continue to seek out ready-to-eat and easy-to-prepare meat products, the need for effective emulsifiers becomes more pronounced. This market is characterized by a wide range of products and innovations aimed at meeting the diverse needs of food manufacturers and consumers alike. The ongoing research and development in this field are expected to lead to more advanced and efficient emulsifiers, further boosting the market's growth and expansion.

Warm Process, Cold Process in the Processed Meat Emulsifier - Global Market:

The processed meat emulsifier market is influenced by two primary processing methods: the warm process and the cold process. Each method has its unique characteristics and applications, impacting the final product's quality and consumer appeal. The warm process involves heating the meat mixture to a specific temperature, allowing the emulsifier to blend the ingredients effectively. This method is particularly beneficial for products that require a smooth and uniform texture, such as sausages and certain types of deli meats. The heat helps in breaking down the proteins and fats, enabling the emulsifier to bind them together seamlessly. This process also aids in enhancing the flavor profile of the meat product, making it more palatable to consumers. On the other hand, the cold process is employed when the preservation of the meat's natural texture and flavor is a priority. In this method, the emulsifier is added to the meat mixture without applying heat, maintaining the integrity of the raw ingredients. This approach is often used for products like cold cuts and specialty meats, where the natural taste and texture are crucial selling points. The cold process is also advantageous in terms of energy efficiency, as it eliminates the need for heating, thus reducing production costs. Both the warm and cold processes have their respective advantages and are chosen based on the desired characteristics of the final product. Manufacturers often select the processing method that aligns with their product goals, consumer preferences, and production capabilities. The choice between warm and cold processes also depends on the type of emulsifier used, as some emulsifiers perform better under specific conditions. For instance, certain emulsifiers are designed to withstand high temperatures, making them ideal for the warm process, while others are more effective in cold environments. The global market for processed meat emulsifiers continues to evolve, with manufacturers exploring new techniques and technologies to optimize these processes. Innovations in emulsifier formulations and processing methods are expected to drive the market forward, offering enhanced product quality and consumer satisfaction. As the demand for processed meat products grows, the importance of selecting the right emulsification process becomes increasingly critical. Manufacturers must consider factors such as product type, consumer preferences, and production efficiency when deciding between warm and cold processes. By understanding the nuances of each method, companies can produce high-quality meat products that meet the evolving needs of the global market.

Sausage, Beef, Pork, Other in the Processed Meat Emulsifier - Global Market:

Processed meat emulsifiers are widely used in various meat products, including sausages, beef, pork, and other types of processed meats. In sausages, emulsifiers play a vital role in ensuring a consistent texture and flavor. They help in binding the meat, fat, and water, preventing separation and maintaining the desired juiciness and taste. This is particularly important in products like hot dogs and bratwursts, where a smooth and uniform texture is essential for consumer satisfaction. Emulsifiers also aid in extending the shelf life of sausages by stabilizing the mixture and reducing the risk of spoilage. In beef products, emulsifiers are used to enhance the quality and appeal of items like beef patties and meatballs. They help in achieving a uniform distribution of fat and moisture, resulting in a tender and flavorful product. Emulsifiers also contribute to the structural integrity of beef products, ensuring they hold their shape during cooking and handling. This is especially important in the production of frozen beef items, where maintaining quality and consistency is crucial. Pork products, such as ham and bacon, also benefit from the use of emulsifiers. These additives help in improving the texture and appearance of pork products, making them more appealing to consumers. Emulsifiers assist in binding the ingredients, preventing separation, and ensuring a uniform distribution of flavors. This is particularly important in processed pork items, where maintaining a consistent quality is key to consumer satisfaction. In addition to sausages, beef, and pork, emulsifiers are used in a variety of other processed meat products. These include deli meats, meat spreads, and specialty items like pâtés and terrines. In these products, emulsifiers help in achieving the desired texture and flavor, enhancing the overall quality and appeal. The versatility of emulsifiers makes them an essential component in the production of a wide range of processed meat products. As the demand for convenient and high-quality meat products continues to grow, the use of emulsifiers in the global market is expected to increase. Manufacturers are continually exploring new formulations and applications to meet the evolving needs of consumers and the food industry. By leveraging the benefits of emulsifiers, companies can produce processed meat products that are not only delicious but also meet the highest standards of quality and safety.

Processed Meat Emulsifier - Global Market Outlook:

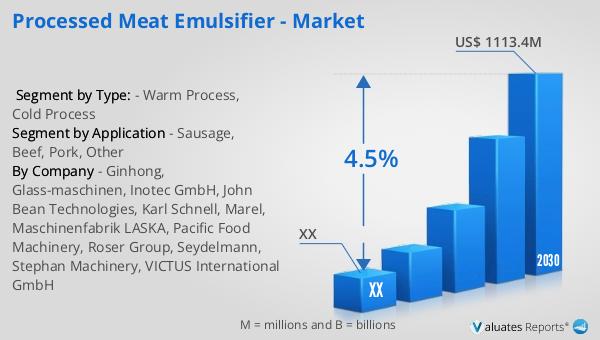

The global market for processed meat emulsifiers was valued at approximately $804 million in 2023. This market is projected to grow significantly, reaching an estimated size of $1,113.4 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.5% during the forecast period from 2024 to 2030. The increasing demand for processed meat products, driven by changing consumer lifestyles and preferences, is a key factor contributing to this market expansion. As more consumers seek convenient and ready-to-eat meat options, the need for effective emulsifiers becomes more pronounced. These additives play a crucial role in enhancing the quality, texture, and shelf life of processed meats, making them an essential component in the food industry. The market's growth is also supported by ongoing innovations in emulsifier formulations and processing techniques, which are expected to offer improved product performance and consumer satisfaction. As the processed meat emulsifier market continues to evolve, manufacturers are likely to explore new opportunities and applications to meet the diverse needs of consumers and the food industry. This growth trajectory highlights the importance of emulsifiers in the global food market and underscores their role in shaping the future of processed meat products.

| Report Metric | Details |

| Report Name | Processed Meat Emulsifier - Market |

| Forecasted market size in 2030 | US$ 1113.4 million |

| CAGR | 4.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Ginhong, Glass-maschinen, Inotec GmbH, John Bean Technologies, Karl Schnell, Marel, Maschinenfabrik LASKA, Pacific Food Machinery, Roser Group, Seydelmann, Stephan Machinery, VICTUS International GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |