What is Microfibrillated Cellulose Fiber - Global Market?

Microfibrillated cellulose fiber, often abbreviated as MFC, is a versatile and sustainable material derived from plant-based cellulose. This fiber is characterized by its high surface area and unique fibrillar structure, which imparts exceptional mechanical properties and stability. MFC is produced through a process that involves breaking down cellulose fibers into much smaller fibrils, resulting in a material that is both lightweight and strong. Its applications are diverse, ranging from paper and packaging to paints and coatings, due to its ability to enhance strength, reduce weight, and improve barrier properties. The global market for MFC is expanding as industries seek sustainable alternatives to traditional materials. With growing environmental concerns and the push for renewable resources, MFC is gaining traction as a key component in various sectors. Its biodegradability and renewable nature make it an attractive option for companies aiming to reduce their carbon footprint. As research and development continue to advance, the potential applications of MFC are expected to broaden, further driving its demand in the global market. The versatility and eco-friendly nature of microfibrillated cellulose fiber position it as a promising material for the future.

Barrier Films, Performance Enhancer in the Microfibrillated Cellulose Fiber - Global Market:

Barrier films enhanced with microfibrillated cellulose fiber represent a significant advancement in material science, offering a sustainable alternative to traditional barrier materials. These films are designed to provide superior protection against moisture, oxygen, and other environmental factors, making them ideal for packaging applications. The incorporation of MFC into barrier films enhances their mechanical strength and flexibility while maintaining transparency, which is crucial for consumer appeal. One of the key advantages of MFC-based barrier films is their biodegradability, which addresses the growing demand for environmentally friendly packaging solutions. As industries worldwide strive to reduce their reliance on fossil fuels and minimize waste, MFC-based films offer a viable solution. The production process of these films involves the integration of MFC into polymer matrices, resulting in a composite material that retains the beneficial properties of both components. This synergy allows for the creation of films that are not only strong and durable but also lightweight and recyclable. The global market for MFC-based barrier films is poised for growth as companies across various sectors, including food and beverage, pharmaceuticals, and electronics, seek to enhance the sustainability of their packaging. In the food industry, for instance, these films can extend the shelf life of products by providing an effective barrier against oxygen and moisture, thereby reducing food waste. Similarly, in the pharmaceutical sector, MFC-based films can protect sensitive products from environmental degradation, ensuring their efficacy and safety. The electronics industry also benefits from these films, as they can safeguard components from moisture and other contaminants, enhancing product longevity. The versatility of MFC-based barrier films extends beyond packaging, with potential applications in agriculture, construction, and textiles. In agriculture, these films can be used as mulch films to protect crops from pests and environmental stressors while promoting biodegradability. In construction, they can serve as vapor barriers, improving energy efficiency and reducing moisture-related issues. In textiles, MFC-based films can enhance the durability and performance of fabrics, offering new possibilities for sustainable fashion. As research and development efforts continue to explore the full potential of MFC, the range of applications for these barrier films is expected to expand, further driving their adoption in the global market. The integration of MFC into barrier films not only addresses environmental concerns but also offers economic benefits by reducing material costs and improving product performance. As industries increasingly prioritize sustainability, the demand for MFC-based barrier films is likely to rise, positioning them as a key player in the future of material science.

Paper, Packaging, Paints and Coatings, Personal Care, Others in the Microfibrillated Cellulose Fiber - Global Market:

Microfibrillated cellulose fiber is finding increasing use across various industries, thanks to its unique properties and sustainable nature. In the paper industry, MFC is used to enhance the strength and durability of paper products while reducing the need for traditional additives. Its high surface area and fibrillar structure allow for better bonding between fibers, resulting in stronger and more resilient paper. This not only improves the quality of the final product but also reduces production costs by minimizing the amount of raw material required. In the packaging sector, MFC is used to create lightweight and strong packaging materials that offer excellent barrier properties. Its ability to form a dense network of fibers makes it an ideal choice for creating films and coatings that protect against moisture, oxygen, and other environmental factors. This is particularly important in the food and beverage industry, where maintaining product freshness and extending shelf life are critical. In the paints and coatings industry, MFC is used as a rheology modifier and performance enhancer. Its unique structure allows it to improve the viscosity and stability of paints, resulting in better application and finish. Additionally, MFC can enhance the mechanical properties of coatings, making them more resistant to wear and tear. This is particularly beneficial in industrial applications where durability is a key requirement. In the personal care industry, MFC is used as a thickening agent and stabilizer in products such as creams, lotions, and gels. Its natural origin and biodegradability make it an attractive alternative to synthetic thickeners, aligning with the growing consumer demand for eco-friendly and sustainable products. MFC also offers sensory benefits, providing a smooth and luxurious feel to personal care formulations. Beyond these industries, MFC is finding applications in areas such as textiles, construction, and automotive. In textiles, MFC can enhance the strength and durability of fabrics, offering new possibilities for sustainable fashion. In construction, it can be used as a reinforcing agent in concrete and other building materials, improving their mechanical properties and reducing their environmental impact. In the automotive industry, MFC is being explored as a lightweight alternative to traditional materials, helping to reduce vehicle weight and improve fuel efficiency. As research and development efforts continue to uncover new applications for MFC, its use in the global market is expected to grow, driven by the increasing demand for sustainable and high-performance materials.

Microfibrillated Cellulose Fiber - Global Market Outlook:

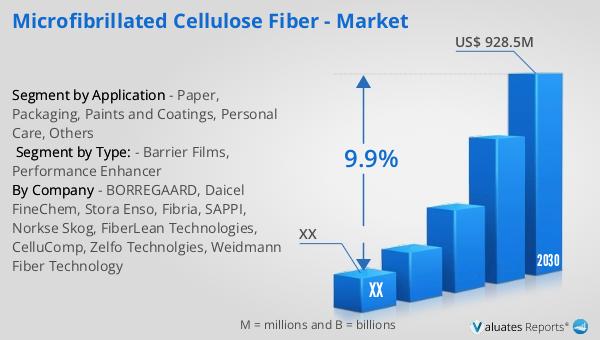

The global market for microfibrillated cellulose fiber was valued at approximately $481 million in 2023. It is projected to grow significantly, reaching an estimated $928.5 million by 2030, with a compound annual growth rate (CAGR) of 9.9% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for sustainable and high-performance materials across various industries. Composites, which include fiber-reinforced materials and organic matrices, are a significant area of application for MFC. Among these, glass fiber reinforced polymer (GFRP) and carbon fiber reinforced polymer (CFRP) composites are the most commonly used materials. These composites are known for their exceptional strength-to-weight ratio and durability, making them ideal for applications in aerospace, automotive, and construction. In addition to GFRP and CFRP, composites reinforced with aramid or natural fibers are also gaining traction, driven by the need for more sustainable and environmentally friendly materials. The integration of MFC into these composites offers several advantages, including improved mechanical properties, reduced weight, and enhanced sustainability. As industries continue to prioritize sustainability and performance, the demand for MFC and its applications in composites is expected to rise, contributing to the overall growth of the global market. The increasing focus on reducing carbon emissions and minimizing environmental impact is further driving the adoption of MFC, positioning it as a key player in the future of material science.

| Report Metric | Details |

| Report Name | Microfibrillated Cellulose Fiber - Market |

| Forecasted market size in 2030 | US$ 928.5 million |

| CAGR | 9.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | BORREGAARD, Daicel FineChem, Stora Enso, Fibria, SAPPI, Norkse Skog, FiberLean Technologies, CelluComp, Zelfo Technolgies, Weidmann Fiber Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |