What is Metal Shell Electronic Packaging - Global Market?

Metal shell electronic packaging is a crucial component in the global market, serving as a protective enclosure for electronic devices and systems. This type of packaging is designed to shield sensitive electronic components from environmental factors such as moisture, dust, and electromagnetic interference, ensuring their optimal performance and longevity. The global market for metal shell electronic packaging is driven by the increasing demand for reliable and durable electronic devices across various industries, including aerospace, automotive, consumer electronics, and industrial applications. As technology continues to advance, the need for more sophisticated and robust packaging solutions has become paramount, leading to innovations in materials and design. Metal shell packaging offers superior thermal management, structural integrity, and electromagnetic shielding compared to other packaging types, making it a preferred choice for high-performance applications. The market is characterized by a diverse range of products, including aluminum and silicon carbide heat sinks, which are integral to managing heat dissipation in electronic systems. As industries continue to push the boundaries of electronic capabilities, the demand for advanced metal shell electronic packaging solutions is expected to grow, further driving market expansion and technological advancements.

Aluminum Heat Sink, Silicon Carbide Heat Sink in the Metal Shell Electronic Packaging - Global Market:

Aluminum heat sinks are a vital component in metal shell electronic packaging, playing a significant role in thermal management. These heat sinks are designed to dissipate heat generated by electronic components, preventing overheating and ensuring the reliability and efficiency of the device. Aluminum is favored for its excellent thermal conductivity, lightweight nature, and cost-effectiveness, making it an ideal material for heat sinks in various applications. In the global market, aluminum heat sinks are widely used in consumer electronics, automotive, and industrial sectors, where efficient heat dissipation is crucial for maintaining optimal performance. The design of aluminum heat sinks can vary, with options such as extruded, stamped, or bonded fin configurations, each offering different levels of thermal performance and cost considerations. Silicon carbide heat sinks, on the other hand, represent a more advanced solution in the realm of metal shell electronic packaging. Silicon carbide is a semiconductor material known for its exceptional thermal conductivity, high-temperature stability, and mechanical strength. These properties make silicon carbide heat sinks particularly suitable for high-power and high-frequency applications, such as those found in aerospace and defense, as well as in advanced automotive systems. The use of silicon carbide heat sinks is gaining traction in the global market due to the increasing demand for high-performance electronic systems that can operate efficiently under extreme conditions. The integration of silicon carbide heat sinks in metal shell electronic packaging offers enhanced thermal management capabilities, allowing for more compact and efficient designs. This is particularly important in applications where space and weight are critical factors, such as in electric vehicles and military equipment. As the global market for metal shell electronic packaging continues to evolve, the demand for both aluminum and silicon carbide heat sinks is expected to rise, driven by the need for more efficient and reliable thermal management solutions. Manufacturers are investing in research and development to improve the performance and cost-effectiveness of these heat sinks, exploring new materials and design techniques to meet the growing demands of the market. The competition between aluminum and silicon carbide heat sinks is likely to intensify as industries seek to balance performance, cost, and environmental considerations in their electronic packaging solutions. Ultimately, the choice between aluminum and silicon carbide heat sinks will depend on the specific requirements of the application, with each offering distinct advantages and trade-offs. As technology continues to advance, the global market for metal shell electronic packaging will witness ongoing innovation and development, paving the way for more efficient and sustainable electronic systems.

Aerospace and Defense, Automotive, Industrial, Consumer electronic, Others in the Metal Shell Electronic Packaging - Global Market:

Metal shell electronic packaging plays a pivotal role in various industries, providing essential protection and performance enhancement for electronic systems. In the aerospace and defense sector, metal shell packaging is crucial for safeguarding sensitive electronic components from harsh environmental conditions, such as extreme temperatures, vibration, and electromagnetic interference. These packaging solutions ensure the reliability and longevity of critical systems used in aircraft, satellites, and military equipment, where failure is not an option. The automotive industry also relies heavily on metal shell electronic packaging to protect the complex electronic systems found in modern vehicles. From engine control units to advanced driver-assistance systems, these packaging solutions help maintain the performance and safety of automotive electronics, even in challenging conditions. In the industrial sector, metal shell electronic packaging is used to protect electronic components in machinery and equipment, ensuring their durability and efficiency in demanding environments. This is particularly important in industries such as manufacturing, energy, and telecommunications, where electronic systems are exposed to harsh conditions and must operate reliably over extended periods. Consumer electronics also benefit from metal shell packaging, which provides the necessary protection for devices such as smartphones, laptops, and wearable technology. These packaging solutions help enhance the durability and performance of consumer electronics, meeting the growing demand for reliable and long-lasting products. Additionally, metal shell electronic packaging is used in other areas, such as medical devices and renewable energy systems, where the protection and performance of electronic components are critical. As the global market for metal shell electronic packaging continues to expand, the demand for innovative and reliable solutions across these industries is expected to grow, driving further advancements in materials and design.

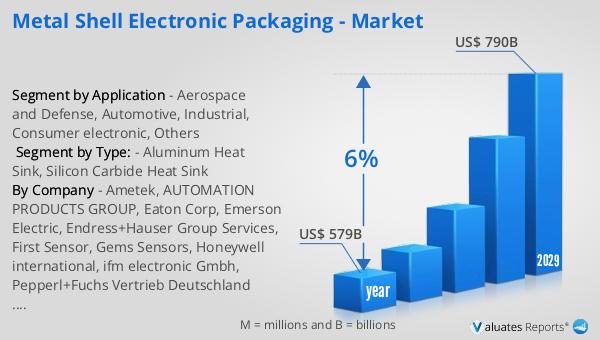

Metal Shell Electronic Packaging - Global Market Outlook:

The global semiconductor market, which was valued at approximately $579 billion in 2022, is anticipated to reach around $790 billion by 2029, reflecting a compound annual growth rate (CAGR) of 6% over the forecast period. This growth trajectory underscores the increasing demand for semiconductors across various industries, driven by technological advancements and the proliferation of electronic devices. Semiconductors are the backbone of modern electronics, powering everything from smartphones and computers to automotive systems and industrial machinery. The projected growth in the semiconductor market is indicative of the expanding role of electronics in our daily lives and the continuous innovation in semiconductor technology. As industries such as automotive, consumer electronics, and telecommunications continue to evolve, the demand for more advanced and efficient semiconductor solutions is expected to rise. This growth is further fueled by the increasing adoption of emerging technologies such as artificial intelligence, the Internet of Things (IoT), and 5G connectivity, which require sophisticated semiconductor components to function effectively. The global semiconductor market's expansion presents significant opportunities for manufacturers and suppliers, encouraging investment in research and development to meet the evolving needs of the market. As the demand for semiconductors continues to grow, the industry is poised for further innovation and development, driving advancements in electronic systems and applications worldwide.

| Report Metric | Details |

| Report Name | Metal Shell Electronic Packaging - Market |

| Accounted market size in year | US$ 579 billion |

| Forecasted market size in 2029 | US$ 790 billion |

| CAGR | 6% |

| Base Year | year |

| Forecasted years | 2024 - 2029 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Ametek, AUTOMATION PRODUCTS GROUP, Eaton Corp, Emerson Electric, Endress+Hauser Group Services, First Sensor, Gems Sensors, Honeywell international, ifm electronic Gmbh, Pepperl+Fuchs Vertrieb Deutschland GmbH, Sapcon Instruments, Siemens AG, SSI Technologies, Stoneridge |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |