What is Medical Thermoplastic Polyurethane Elastomer - Global Market?

Medical Thermoplastic Polyurethane Elastomer is a specialized material used extensively in the healthcare industry due to its unique properties. This elastomer is a type of plastic that combines the elasticity of rubber with the toughness and durability of metal, making it ideal for medical applications. It is highly valued for its flexibility, biocompatibility, and resistance to chemicals and abrasion. These properties make it suitable for a wide range of medical devices and equipment, including catheters, surgical instruments, and wound care products. The global market for Medical Thermoplastic Polyurethane Elastomer is driven by the increasing demand for advanced medical devices and the growing healthcare sector worldwide. As healthcare providers seek materials that can withstand sterilization processes and provide comfort and safety to patients, the demand for this elastomer continues to rise. Additionally, the material's ability to be easily molded into complex shapes allows for innovation in medical device design, further fueling its market growth. The global market is also influenced by technological advancements and the increasing prevalence of chronic diseases, which necessitate the development of more sophisticated medical solutions. Overall, the Medical Thermoplastic Polyurethane Elastomer market is poised for significant growth as it continues to meet the evolving needs of the healthcare industry.

Polyester-Based, Polyether-Based, Others in the Medical Thermoplastic Polyurethane Elastomer - Global Market:

Medical Thermoplastic Polyurethane Elastomer can be categorized into three main types based on its chemical composition: Polyester-Based, Polyether-Based, and Others. Each type has distinct characteristics that make it suitable for specific medical applications. Polyester-Based elastomers are known for their excellent mechanical properties, including high tensile strength and resistance to wear and tear. These properties make them ideal for applications that require durability and long-term performance, such as in the manufacturing of medical tubing and catheters. Polyester-Based elastomers also offer good resistance to oils and chemicals, which is crucial in medical environments where exposure to various substances is common. On the other hand, Polyether-Based elastomers are prized for their superior flexibility and hydrolytic stability. This means they can withstand prolonged exposure to moisture without degrading, making them suitable for applications involving bodily fluids or environments with high humidity. Polyether-Based elastomers are often used in the production of medical films, coatings, and adhesives, where flexibility and moisture resistance are paramount. The "Others" category includes elastomers that are modified or blended with other materials to enhance specific properties. These may include elastomers with antimicrobial properties or those designed for specific applications like drug delivery systems. The versatility of Medical Thermoplastic Polyurethane Elastomers allows manufacturers to tailor the material to meet the precise requirements of different medical devices, ensuring optimal performance and patient safety. As the global market for these elastomers continues to expand, driven by advancements in medical technology and the increasing demand for high-performance materials, the development of new formulations and applications is expected to further enhance their role in the healthcare industry.

Surgical Gown and Cap, Bandages, Plasma Bag, Others in the Medical Thermoplastic Polyurethane Elastomer - Global Market:

Medical Thermoplastic Polyurethane Elastomer is widely used in various medical applications due to its unique properties. In the production of surgical gowns and caps, this elastomer provides a combination of comfort, flexibility, and protection. Its ability to be easily molded into thin films allows for the creation of lightweight and breathable garments that offer a barrier against contaminants. The material's resistance to chemicals and abrasion ensures that these protective garments can withstand the rigors of surgical environments, providing safety for healthcare professionals. In the case of bandages, Medical Thermoplastic Polyurethane Elastomer offers excellent adhesion and flexibility, allowing for secure and comfortable wound coverage. Its biocompatibility ensures that it does not cause irritation or allergic reactions, making it suitable for sensitive skin. The elastomer's moisture resistance also helps in maintaining a sterile environment around the wound, promoting faster healing. For plasma bags, the elastomer's durability and chemical resistance are crucial. These bags need to withstand various storage conditions and handling processes without compromising the integrity of the plasma. The elastomer's flexibility allows for easy handling and transportation, ensuring that the plasma remains safe and uncontaminated. Additionally, the "Others" category includes a wide range of medical devices and equipment that benefit from the properties of Medical Thermoplastic Polyurethane Elastomer. This includes items like catheters, tubing, and medical films, where the material's flexibility, durability, and biocompatibility are essential. As the demand for advanced medical solutions continues to grow, the use of Medical Thermoplastic Polyurethane Elastomer in these applications is expected to increase, driven by the need for materials that can meet the stringent requirements of the healthcare industry.

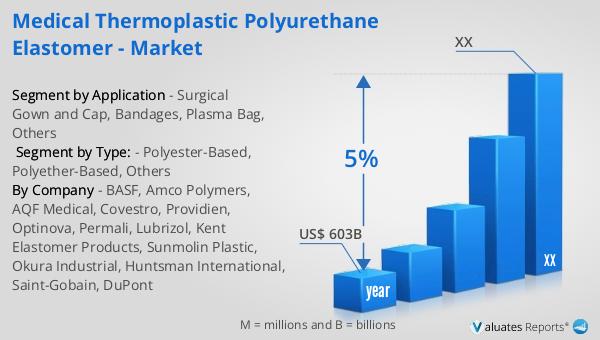

Medical Thermoplastic Polyurethane Elastomer - Global Market Outlook:

Our research indicates that the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including the increasing prevalence of chronic diseases, advancements in medical technology, and the rising demand for innovative healthcare solutions. As the global population continues to age, there is a growing need for medical devices that can improve the quality of life for patients and provide effective treatment options. Additionally, the ongoing development of new medical technologies and the increasing adoption of digital health solutions are contributing to the expansion of the market. The demand for high-performance materials like Medical Thermoplastic Polyurethane Elastomer is also expected to rise, as healthcare providers seek materials that can enhance the functionality and safety of medical devices. This growth presents significant opportunities for manufacturers and suppliers in the medical device industry, as they work to meet the evolving needs of healthcare providers and patients worldwide. As the market continues to expand, the focus on innovation and quality will be crucial in driving the development of new products and solutions that can address the challenges facing the healthcare industry.

| Report Metric | Details |

| Report Name | Medical Thermoplastic Polyurethane Elastomer - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | BASF, Amco Polymers, AQF Medical, Covestro, Providien, Optinova, Permali, Lubrizol, Kent Elastomer Products, Sunmolin Plastic, Okura Industrial, Huntsman International, Saint-Gobain, DuPont |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |