What is Intelligent Bearingless Rotary Encoders - Global Market?

Intelligent Bearingless Rotary Encoders are a sophisticated type of sensor used to measure the rotational position and speed of an object without the need for physical bearings. These encoders are designed to operate in environments where traditional encoders might fail due to wear and tear or contamination. By eliminating the need for bearings, these encoders offer increased reliability and longevity, making them ideal for applications in harsh or demanding environments. The global market for these encoders is driven by the growing demand for precision and efficiency in various industrial applications. Industries such as manufacturing, robotics, and automation are increasingly adopting these encoders to enhance the performance and reliability of their systems. The market is characterized by continuous technological advancements, with manufacturers focusing on developing more compact, efficient, and cost-effective solutions. As industries continue to evolve and demand more sophisticated sensing technologies, the market for Intelligent Bearingless Rotary Encoders is expected to grow, driven by the need for high-performance, maintenance-free solutions.

Absolute Rotary Encoder, Incremental Rotary Encoder in the Intelligent Bearingless Rotary Encoders - Global Market:

Absolute Rotary Encoders and Incremental Rotary Encoders are two primary types of encoders used in the Intelligent Bearingless Rotary Encoders market. Absolute Rotary Encoders provide a unique position value for each shaft position, ensuring that the exact position is known even after a power loss. This feature makes them highly reliable for applications where precise position tracking is crucial, such as in robotics and industrial automation. These encoders are often used in systems where accuracy and repeatability are paramount, as they can provide exact position data without the need for a reference point. On the other hand, Incremental Rotary Encoders provide relative position information by generating a series of pulses as the shaft rotates. These pulses can be counted to determine the position or speed of the rotating object. Incremental encoders are typically used in applications where speed and direction information is more critical than absolute position, such as in conveyor systems or motor feedback applications. Both types of encoders have their unique advantages and are chosen based on the specific requirements of the application. The global market for these encoders is influenced by factors such as technological advancements, increasing automation in industries, and the need for precise motion control solutions. As industries continue to adopt more automated and efficient systems, the demand for both Absolute and Incremental Rotary Encoders is expected to rise. Manufacturers are focusing on developing encoders with enhanced features such as higher resolution, better accuracy, and improved durability to meet the evolving needs of various industries. The market is also witnessing a trend towards miniaturization, with compact and lightweight encoders gaining popularity in applications where space is a constraint. Additionally, the integration of advanced technologies such as IoT and AI in encoder systems is opening new avenues for growth in the market. These technologies enable real-time monitoring and predictive maintenance, enhancing the overall efficiency and reliability of the systems in which these encoders are used. As the global market for Intelligent Bearingless Rotary Encoders continues to expand, both Absolute and Incremental Rotary Encoders are expected to play a significant role in driving this growth.

Machine Tool, Servo Motor, Metal Forming and Fabrication, Other in the Intelligent Bearingless Rotary Encoders - Global Market:

Intelligent Bearingless Rotary Encoders are widely used in various industrial applications, including Machine Tool, Servo Motor, Metal Forming and Fabrication, and other sectors. In the Machine Tool industry, these encoders are essential for ensuring precise control and positioning of machine components. They help in achieving high accuracy and repeatability, which are critical for producing high-quality parts and components. The use of these encoders in machine tools enhances the overall efficiency and productivity of the manufacturing process, reducing downtime and maintenance costs. In Servo Motors, Intelligent Bearingless Rotary Encoders provide accurate feedback on the motor's position and speed, enabling precise control of the motor's operation. This is crucial for applications that require high precision and dynamic performance, such as robotics and automation systems. The encoders help in optimizing the performance of servo motors, improving their efficiency and reliability. In the Metal Forming and Fabrication industry, these encoders are used to monitor and control the position and movement of metal forming machines. They ensure that the machines operate with high precision and accuracy, resulting in high-quality metal products. The use of Intelligent Bearingless Rotary Encoders in this industry helps in reducing material waste and improving the overall efficiency of the production process. Apart from these specific applications, these encoders are also used in various other industries where precise motion control and position feedback are required. Their ability to operate in harsh environments without the need for maintenance makes them ideal for use in industries such as aerospace, automotive, and renewable energy. The global market for Intelligent Bearingless Rotary Encoders is driven by the increasing demand for automation and precision in these industries. As industries continue to evolve and adopt more advanced technologies, the use of these encoders is expected to grow, contributing to the overall growth of the market.

Intelligent Bearingless Rotary Encoders - Global Market Outlook:

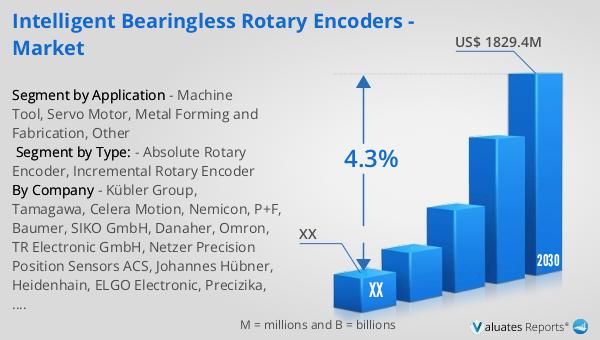

The global market for Intelligent Bearingless Rotary Encoders was valued at approximately $2,314 million in 2023. However, it is projected to undergo a readjustment, reaching an estimated size of $1,829.4 million by 2030, with a compound annual growth rate (CAGR) of 4.3% during the forecast period from 2024 to 2030. This indicates a dynamic market landscape, influenced by various factors such as technological advancements and changing industry demands. In North America, the market for these encoders was valued at a certain amount in 2023, and it is anticipated to reach a different value by 2030, maintaining a specific CAGR throughout the forecast period. This regional market outlook reflects the broader trends and shifts occurring globally, as industries increasingly seek efficient and reliable solutions for motion control and position feedback. The market's evolution is driven by the growing need for precision and automation across various sectors, including manufacturing, robotics, and renewable energy. As industries continue to embrace advanced technologies and automation, the demand for Intelligent Bearingless Rotary Encoders is expected to remain robust, contributing to the overall growth and development of the market.

| Report Metric | Details |

| Report Name | Intelligent Bearingless Rotary Encoders - Market |

| Forecasted market size in 2030 | US$ 1829.4 million |

| CAGR | 4.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Kübler Group, Tamagawa, Celera Motion, Nemicon, P+F, Baumer, SIKO GmbH, Danaher, Omron, TR Electronic GmbH, Netzer Precision Position Sensors ACS, Johannes Hübner, Heidenhain, ELGO Electronic, Precizika, Contelec AG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |