What is Industrial Thermal Mass Flow Meters - Global Market?

Industrial Thermal Mass Flow Meters are essential instruments used globally to measure the flow of gases in various industrial applications. These devices operate based on the principle of thermal dispersion, where the flow rate of a gas is determined by measuring the heat loss from a heated element to the flowing gas. This technology is highly valued for its accuracy, reliability, and ability to measure low flow rates, making it indispensable in industries such as chemical processing, oil and gas, and wastewater treatment. The global market for these meters is expanding as industries increasingly seek precise and efficient flow measurement solutions to enhance operational efficiency and reduce costs. The demand is driven by the need for better process control and automation, which are critical in maintaining product quality and optimizing resource use. As industries continue to evolve with technological advancements, the role of thermal mass flow meters becomes even more significant, ensuring that processes are not only efficient but also environmentally sustainable. The global market outlook for these devices is promising, with continuous innovations and improvements in technology expected to further boost their adoption across various sectors.

Rate of Heat Loss Flowmeters, Temperature Rise Flowmeters in the Industrial Thermal Mass Flow Meters - Global Market:

Rate of Heat Loss Flowmeters and Temperature Rise Flowmeters are two critical types of Industrial Thermal Mass Flow Meters that play a significant role in the global market. Rate of Heat Loss Flowmeters work by measuring the amount of heat lost from a heated sensor to the gas flowing past it. This type of flowmeter is particularly effective in applications where the gas composition is stable, and the flow conditions are consistent. It provides accurate measurements by calculating the heat transfer rate, which correlates directly with the mass flow rate of the gas. These flowmeters are widely used in industries such as chemical processing and power generation, where precise gas flow measurement is crucial for process optimization and safety. On the other hand, Temperature Rise Flowmeters operate by measuring the temperature increase of a sensor as it is heated by the flowing gas. The temperature rise is proportional to the mass flow rate, allowing for accurate flow measurement even in varying gas compositions and flow conditions. This type of flowmeter is highly versatile and can be used in a wide range of applications, including environmental monitoring and industrial gas flow measurement. Both types of flowmeters offer distinct advantages and are chosen based on the specific requirements of the application. The global market for these flowmeters is driven by the increasing demand for accurate and reliable flow measurement solutions in various industries. As industries continue to adopt advanced technologies for process automation and control, the demand for these flowmeters is expected to grow significantly. The versatility and accuracy of these devices make them indispensable tools in modern industrial processes, ensuring that operations are efficient, safe, and environmentally friendly. The global market outlook for Rate of Heat Loss Flowmeters and Temperature Rise Flowmeters is positive, with continuous advancements in technology expected to further enhance their performance and expand their applications across different sectors.

Textile Mills, Food Packaging Plants, Groundwater Remediation, Printing Plants, Bottling Plants, Others in the Industrial Thermal Mass Flow Meters - Global Market:

Industrial Thermal Mass Flow Meters find extensive usage in various sectors, including Textile Mills, Food Packaging Plants, Groundwater Remediation, Printing Plants, Bottling Plants, and others. In Textile Mills, these flow meters are crucial for monitoring and controlling the flow of gases used in dyeing and finishing processes. Accurate gas flow measurement ensures consistent product quality and efficient resource utilization, which are vital for maintaining competitiveness in the textile industry. In Food Packaging Plants, thermal mass flow meters are used to measure the flow of gases such as nitrogen and carbon dioxide, which are essential for preserving food quality and extending shelf life. Precise gas flow control is critical in ensuring that packaging processes are efficient and meet stringent quality standards. Groundwater Remediation projects also benefit from the use of thermal mass flow meters, as they provide accurate measurements of gas flow rates used in soil vapor extraction and air sparging processes. These applications require precise control of gas flow to effectively remove contaminants from groundwater, making thermal mass flow meters indispensable tools in environmental remediation efforts. In Printing Plants, these flow meters are used to measure the flow of gases used in drying and curing processes. Accurate gas flow measurement ensures that printing processes are efficient and produce high-quality results. Bottling Plants also rely on thermal mass flow meters to measure the flow of gases used in carbonation and bottling processes. Precise gas flow control is essential in ensuring that beverages are carbonated to the desired level and that bottling processes are efficient and meet quality standards. Other industries that benefit from the use of thermal mass flow meters include chemical processing, oil and gas, and wastewater treatment, where accurate gas flow measurement is critical for process optimization and safety. The global market for these devices is driven by the increasing demand for accurate and reliable flow measurement solutions across various industries. As industries continue to evolve with technological advancements, the role of thermal mass flow meters becomes even more significant, ensuring that processes are not only efficient but also environmentally sustainable.

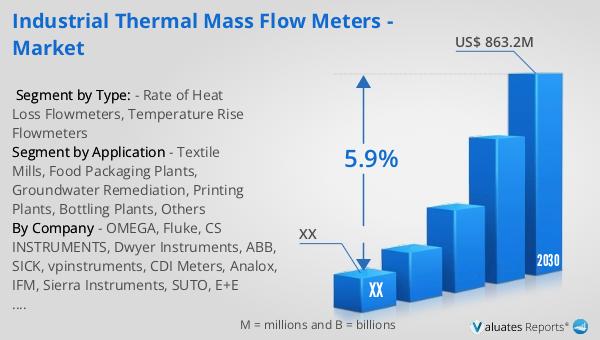

Industrial Thermal Mass Flow Meters - Global Market Outlook:

The global market for Industrial Thermal Mass Flow Meters was valued at approximately US$ 584 million in 2023, with projections indicating a growth to US$ 863.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.9% during the forecast period from 2024 to 2030. This growth is primarily driven by the increasing adoption of Industry 4.0 and the rising need for process automation and control across various industries. As industries strive to enhance operational efficiency and reduce costs, the demand for precise and reliable flow measurement solutions is on the rise. Industrial Thermal Mass Flow Meters offer the accuracy and reliability needed to meet these demands, making them indispensable tools in modern industrial processes. The integration of advanced technologies in industrial operations is further fueling the demand for these devices, as they play a crucial role in ensuring that processes are efficient, safe, and environmentally friendly. The global market outlook for Industrial Thermal Mass Flow Meters is promising, with continuous innovations and improvements in technology expected to further boost their adoption across various sectors. As industries continue to evolve and embrace new technologies, the role of thermal mass flow meters becomes even more significant, ensuring that processes are not only efficient but also sustainable.

| Report Metric | Details |

| Report Name | Industrial Thermal Mass Flow Meters - Market |

| Forecasted market size in 2030 | US$ 863.2 million |

| CAGR | 5.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | OMEGA, Fluke, CS INSTRUMENTS, Dwyer Instruments, ABB, SICK, vpinstruments, CDI Meters, Analox, IFM, Sierra Instruments, SUTO, E+E Elektronik, SCHMIDT Technology, ONICON Incorporated, EXAIR Corporation, FLEXIM, Fluid Components International, Testo SE&Co.KGaA, Sigma |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |