What is High Purity Aluminium Powder - Global Market?

High purity aluminium powder is a specialized material that plays a crucial role in various industries due to its unique properties. This powder is characterized by its high level of purity, typically exceeding 99.99%, which makes it suitable for applications requiring exceptional quality and performance. The global market for high purity aluminium powder is driven by its demand in sectors such as electronics, aerospace, and automotive, where it is used for its excellent conductivity, lightweight nature, and resistance to corrosion. The production of high purity aluminium powder involves advanced refining processes to remove impurities, ensuring that the final product meets stringent industry standards. As industries continue to innovate and develop new technologies, the demand for high purity aluminium powder is expected to grow, making it a vital component in the global supply chain. The market is also influenced by factors such as technological advancements, environmental regulations, and the availability of raw materials, which can impact production costs and pricing. Overall, high purity aluminium powder is a key material that supports the advancement of modern technology and industrial applications.

4N, 4N5, 5N, 5N5+ in the High Purity Aluminium Powder - Global Market:

High purity aluminium powder is categorized based on its purity levels, with common grades being 4N, 4N5, 5N, and 5N5+. These grades indicate the percentage of aluminium content, with 4N representing 99.99% purity, 4N5 representing 99.995%, 5N representing 99.999%, and 5N5+ indicating even higher purity levels. Each grade serves specific applications depending on the required level of purity. The 4N grade is often used in applications where high conductivity and corrosion resistance are essential, such as in the electronics industry for manufacturing components like capacitors and semiconductors. The 4N5 grade, with slightly higher purity, is preferred in applications that demand even greater precision and reliability, such as in the production of high-performance alloys and specialized coatings. The 5N grade, with its ultra-high purity, is crucial in the aerospace industry, where materials must withstand extreme conditions and maintain structural integrity. This grade is also used in the production of advanced ceramics and in the chemical industry for catalyst applications, where impurities could significantly affect performance. The 5N5+ grade, representing the pinnacle of purity, is reserved for the most demanding applications, such as in the production of optical materials and in research and development settings where any impurity could compromise results. The global market for high purity aluminium powder is shaped by the demand for these various grades, with manufacturers focusing on refining processes to achieve the desired purity levels. The production of these high-purity grades involves sophisticated techniques such as vacuum distillation and zone refining, which help eliminate impurities and ensure consistency in quality. As industries continue to push the boundaries of technology, the demand for higher purity levels is expected to increase, driving innovation in production methods and expanding the market for high purity aluminium powder. The choice of grade depends on the specific requirements of the application, with higher purity levels generally commanding higher prices due to the complexity of the production process. Manufacturers must balance the cost of production with the market demand to remain competitive, often investing in research and development to improve efficiency and reduce costs. The global market for high purity aluminium powder is also influenced by regional factors, such as the availability of raw materials, energy costs, and environmental regulations, which can impact production and pricing. Overall, the market for high purity aluminium powder is dynamic and evolving, driven by the need for advanced materials in a wide range of industries.

Electronic Industry, Chemical Industry, High Purity Alloy, Other Applications in the High Purity Aluminium Powder - Global Market:

High purity aluminium powder finds extensive use across various industries due to its exceptional properties. In the electronic industry, it is a critical material for manufacturing components such as capacitors, semiconductors, and conductive pastes. Its high conductivity and purity make it ideal for applications where electrical performance is paramount. The powder is used in the production of thin films and coatings that enhance the efficiency and reliability of electronic devices. In the chemical industry, high purity aluminium powder serves as a catalyst in various reactions, where its purity ensures that the chemical processes are not contaminated by impurities. It is also used in the production of specialty chemicals and pharmaceuticals, where high standards of purity are required to ensure product quality and safety. In the field of high purity alloys, aluminium powder is used to create materials with enhanced properties, such as increased strength, corrosion resistance, and thermal stability. These alloys are used in demanding applications such as aerospace, automotive, and defense, where performance and reliability are critical. The powder's ability to form uniform and stable alloys makes it a valuable component in the development of advanced materials. Beyond these industries, high purity aluminium powder is also used in other applications such as the production of advanced ceramics, where its purity and fine particle size contribute to the material's mechanical and thermal properties. It is also used in the production of optical materials, where any impurities could affect the clarity and performance of the final product. The versatility of high purity aluminium powder makes it a key material in the development of new technologies and applications, supporting innovation across a wide range of industries. As industries continue to evolve and demand higher performance materials, the role of high purity aluminium powder is expected to grow, driving advancements in production techniques and expanding its applications. The global market for high purity aluminium powder is characterized by its diversity, with manufacturers catering to a wide range of industries and applications, each with its specific requirements and standards. This diversity presents both challenges and opportunities for manufacturers, who must navigate the complexities of production and market demand to remain competitive. Overall, high purity aluminium powder is a vital material that supports the advancement of modern technology and industrial applications, with its usage spanning a wide range of industries and applications.

High Purity Aluminium Powder - Global Market Outlook:

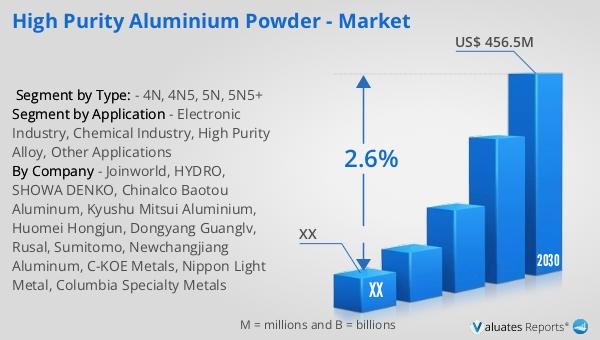

The global market for high purity aluminium powder was valued at approximately $380 million in 2023, with projections indicating a growth to around $456.5 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 2.6% during the forecast period from 2024 to 2030. The Asia-Pacific region holds the largest share of the aluminium powder market, accounting for about 50% of the total market. This is followed by Europe and North America, which also contribute significantly to the market. Key players in the industry include Alcoa, Kymera International, UC RUSAL, Toyal Group, and Xinfa Group, which collectively hold approximately 40% of the market share. These companies are at the forefront of production and innovation, driving the market forward with their expertise and technological advancements. The market dynamics are influenced by factors such as regional demand, technological developments, and the availability of raw materials, which can impact production costs and pricing. As industries continue to evolve and demand higher performance materials, the role of high purity aluminium powder is expected to grow, driving advancements in production techniques and expanding its applications. The global market for high purity aluminium powder is characterized by its diversity, with manufacturers catering to a wide range of industries and applications, each with its specific requirements and standards. This diversity presents both challenges and opportunities for manufacturers, who must navigate the complexities of production and market demand to remain competitive. Overall, high purity aluminium powder is a vital material that supports the advancement of modern technology and industrial applications, with its usage spanning a wide range of industries and applications.

| Report Metric | Details |

| Report Name | High Purity Aluminium Powder - Market |

| Forecasted market size in 2030 | US$ 456.5 million |

| CAGR | 2.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Joinworld, HYDRO, SHOWA DENKO, Chinalco Baotou Aluminum, Kyushu Mitsui Aluminium, Huomei Hongjun, Dongyang Guanglv, Rusal, Sumitomo, Newchangjiang Aluminum, C-KOE Metals, Nippon Light Metal, Columbia Specialty Metals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |