What is Global Copper Head Hammer Market?

The Global Copper Head Hammer Market is a specialized segment within the broader tool industry, focusing on hammers with copper heads. These hammers are particularly valued for their non-sparking and non-marring properties, making them ideal for use in environments where safety is paramount, such as in the presence of flammable materials or delicate surfaces. Copper head hammers are often used in industries like automotive, construction, and manufacturing, where precision and safety are critical. The market for these tools is driven by the demand for durable and reliable tools that can withstand rigorous use without causing damage to the work surface or creating hazardous sparks. As industries continue to prioritize safety and efficiency, the demand for copper head hammers is expected to grow. This market is characterized by a variety of products that cater to different needs, including variations in handle materials and hammer sizes, allowing users to select the most appropriate tool for their specific applications. The global reach of this market indicates a widespread recognition of the benefits offered by copper head hammers, making them a staple in many professional toolkits.

Wooden Handle, Fiberglass Handle, Steel Handle in the Global Copper Head Hammer Market:

In the Global Copper Head Hammer Market, the choice of handle material is crucial as it affects the hammer's performance, durability, and user comfort. Wooden handles are traditional and have been used for centuries due to their natural shock-absorbing properties. They provide a comfortable grip and are relatively lightweight, making them easy to handle for extended periods. However, wooden handles can be susceptible to wear and tear, especially in harsh environments, and may require regular maintenance to prevent splintering or breaking. Despite these drawbacks, many users prefer wooden handles for their classic feel and the ease with which they can be replaced if damaged. On the other hand, fiberglass handles offer a modern alternative with enhanced durability and resistance to environmental factors. Fiberglass is known for its strength and ability to absorb shock, reducing the strain on the user's hand and wrist during prolonged use. These handles are also resistant to moisture and chemicals, making them suitable for use in various industrial settings. Fiberglass handles are often favored for their low maintenance requirements and long lifespan, although they may be slightly heavier than wooden handles. Steel handles represent the pinnacle of durability and strength in the copper head hammer market. They are virtually indestructible and can withstand the most demanding applications without bending or breaking. Steel handles are ideal for heavy-duty tasks where maximum force is required, and they provide a solid, reliable feel. However, the increased weight of steel handles can be a disadvantage for some users, leading to fatigue during extended use. Additionally, steel handles do not absorb shock as effectively as wood or fiberglass, which can result in increased vibration and discomfort. Despite these challenges, steel handles are often chosen for their unmatched strength and longevity, particularly in professional settings where tool failure is not an option. Each handle material offers distinct advantages and disadvantages, and the choice often depends on the specific needs and preferences of the user. Whether prioritizing comfort, durability, or strength, the Global Copper Head Hammer Market provides a range of options to meet the diverse demands of its users.

Indoor, Outdoor in the Global Copper Head Hammer Market:

The usage of copper head hammers spans both indoor and outdoor applications, each with its unique requirements and challenges. Indoors, copper head hammers are often used in environments where precision and care are paramount. For instance, in automotive workshops, these hammers are employed to work on delicate parts without causing damage or leaving marks. The non-sparking nature of copper is particularly beneficial in indoor settings where flammable materials may be present, reducing the risk of accidental ignition. Additionally, in manufacturing facilities, copper head hammers are used to assemble or disassemble machinery, ensuring that components are not marred or damaged during the process. The ergonomic design of these hammers, combined with the choice of handle materials, allows for comfortable use over extended periods, making them ideal for repetitive tasks. Outdoors, copper head hammers are equally valuable, particularly in construction and maintenance work. Their durability and resistance to environmental factors make them suitable for use in various weather conditions. In construction, these hammers are used for tasks such as driving stakes or assembling scaffolding, where the non-marring properties of copper prevent damage to surfaces. The robust design of copper head hammers ensures they can withstand the rigors of outdoor work, providing reliable performance even in challenging conditions. Furthermore, in outdoor maintenance tasks, such as repairing pipelines or electrical installations, the non-sparking feature of copper head hammers is crucial for safety, especially in potentially explosive environments. The versatility of copper head hammers makes them an essential tool for both indoor and outdoor applications, offering a combination of safety, precision, and durability that is unmatched by other types of hammers. Whether used in a controlled indoor environment or the unpredictable outdoors, copper head hammers deliver consistent performance, making them a preferred choice for professionals across various industries.

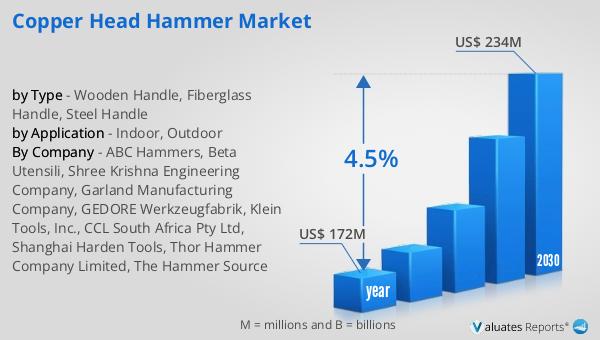

Global Copper Head Hammer Market Outlook:

The global market for copper head hammers was valued at approximately $172 million in 2023. This market is anticipated to expand significantly, reaching an estimated size of $234 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 4.5% over the forecast period. The steady increase in market size reflects the growing demand for copper head hammers across various industries, driven by their unique properties and versatility. As industries continue to prioritize safety and efficiency, the adoption of copper head hammers is expected to rise, contributing to the market's expansion. The projected growth also indicates a broader recognition of the benefits offered by these tools, such as their non-sparking and non-marring characteristics, which are crucial in many professional settings. The market's upward trend suggests that manufacturers and suppliers will continue to innovate and develop new products to meet the evolving needs of their customers. This growth is not only a testament to the value of copper head hammers but also highlights the importance of investing in high-quality tools that enhance safety and productivity. As the market continues to evolve, stakeholders can expect to see further advancements in product design and functionality, ensuring that copper head hammers remain a vital component of toolkits worldwide.

| Report Metric | Details |

| Report Name | Copper Head Hammer Market |

| Accounted market size in year | US$ 172 million |

| Forecasted market size in 2030 | US$ 234 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABC Hammers, Beta Utensili, Shree Krishna Engineering Company, Garland Manufacturing Company, GEDORE Werkzeugfabrik, Klein Tools, Inc., CCL South Africa Pty Ltd, Shanghai Harden Tools, Thor Hammer Company Limited, The Hammer Source |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |