What is Functional Coatings for Medical Devices - Global Market?

Functional coatings for medical devices represent a specialized segment within the broader medical device industry, focusing on enhancing the performance and safety of medical tools through advanced surface treatments. These coatings are applied to medical devices to improve their functionality, durability, and biocompatibility. They serve various purposes, such as reducing friction, preventing bacterial growth, and enhancing the device's interaction with biological tissues. The global market for functional coatings is driven by the increasing demand for minimally invasive surgical procedures, which require devices with superior performance characteristics. Additionally, the rising prevalence of chronic diseases and the aging population contribute to the growing need for advanced medical devices, further propelling the market. Technological advancements in coating materials and application techniques also play a crucial role in market expansion. Companies in this sector are continually innovating to develop coatings that meet stringent regulatory standards while providing enhanced functionality. As healthcare systems worldwide strive for better patient outcomes and cost efficiency, the adoption of functional coatings in medical devices is expected to rise, making it a vital component of the medical device industry.

Hydrophilic, Antibacterial, Anticoagulant, Others in the Functional Coatings for Medical Devices - Global Market:

Functional coatings for medical devices encompass a variety of specialized coatings, each serving distinct purposes to enhance the performance and safety of medical tools. Hydrophilic coatings, for instance, are designed to attract and retain water, creating a lubricious surface that reduces friction. This is particularly beneficial in devices like catheters and guide wires, where ease of insertion and maneuverability are crucial. By minimizing friction, hydrophilic coatings help reduce patient discomfort and the risk of tissue damage during procedures. Antibacterial coatings, on the other hand, are engineered to prevent the growth and spread of harmful bacteria on medical devices. These coatings are essential in reducing the risk of infections, especially in devices that remain in contact with the body for extended periods, such as implants and surgical instruments. By incorporating antimicrobial agents, these coatings provide an additional layer of protection against hospital-acquired infections, which are a significant concern in healthcare settings. Anticoagulant coatings are another critical category, designed to prevent blood clot formation on medical devices that come into contact with blood, such as stents and vascular grafts. These coatings work by inhibiting the coagulation cascade, thereby reducing the risk of thrombosis and ensuring the smooth flow of blood through the device. This is particularly important in cardiovascular applications, where blood clots can have severe consequences. Other functional coatings include anti-fog, anti-reflective, and drug-eluting coatings, each tailored to specific medical applications. Anti-fog coatings are used in optical devices like endoscopes to maintain clear visibility during procedures, while anti-reflective coatings enhance the optical clarity of lenses and screens. Drug-eluting coatings are designed to release therapeutic agents over time, providing localized treatment and reducing the need for systemic medication. These coatings are commonly used in drug-eluting stents, which release anti-proliferative drugs to prevent restenosis in coronary arteries. The development and application of these functional coatings require a deep understanding of material science and the specific requirements of each medical device. Manufacturers must ensure that the coatings are biocompatible, durable, and capable of withstanding the harsh conditions of the human body. Regulatory compliance is also a critical consideration, as coatings must meet stringent safety and efficacy standards set by health authorities. As the demand for advanced medical devices continues to grow, the market for functional coatings is expected to expand, driven by ongoing research and innovation in coating technologies.

Catheter, Stent Delivery System, Guide Wire, Others in the Functional Coatings for Medical Devices - Global Market:

Functional coatings for medical devices play a crucial role in enhancing the performance and safety of various medical tools, including catheters, stent delivery systems, guide wires, and others. In the case of catheters, hydrophilic coatings are commonly used to create a lubricious surface that facilitates smooth insertion and navigation through the body's intricate pathways. This reduces friction, minimizes patient discomfort, and lowers the risk of tissue damage during procedures. Additionally, antibacterial coatings on catheters help prevent infections, a critical consideration given the device's prolonged contact with the body. Stent delivery systems also benefit significantly from functional coatings. Anticoagulant coatings are particularly important in these devices, as they help prevent blood clot formation during and after the stent placement. By reducing the risk of thrombosis, these coatings ensure the stent remains patent and functional, improving patient outcomes in cardiovascular interventions. Furthermore, drug-eluting coatings on stents release therapeutic agents over time, preventing restenosis and enhancing the long-term success of the procedure. Guide wires, essential tools in various minimally invasive procedures, also utilize functional coatings to improve their performance. Hydrophilic coatings on guide wires reduce friction, allowing for easier navigation through blood vessels and other anatomical structures. This enhances the precision and control of the procedure, reducing the risk of complications. Additionally, anti-fog and anti-reflective coatings on optical components of guide wires ensure clear visibility during procedures, aiding in accurate device placement. Beyond these specific applications, functional coatings are used in a wide range of other medical devices, each tailored to meet the unique demands of the device and the procedure. For instance, anti-fog coatings are applied to endoscopes and other optical devices to maintain clear visibility during procedures, while anti-reflective coatings enhance the optical clarity of lenses and screens. Drug-eluting coatings are used in various implants and devices to provide localized treatment and reduce the need for systemic medication. The development and application of functional coatings require a deep understanding of material science and the specific requirements of each medical device. Manufacturers must ensure that the coatings are biocompatible, durable, and capable of withstanding the harsh conditions of the human body. Regulatory compliance is also a critical consideration, as coatings must meet stringent safety and efficacy standards set by health authorities. As the demand for advanced medical devices continues to grow, the market for functional coatings is expected to expand, driven by ongoing research and innovation in coating technologies.

Functional Coatings for Medical Devices - Global Market Outlook:

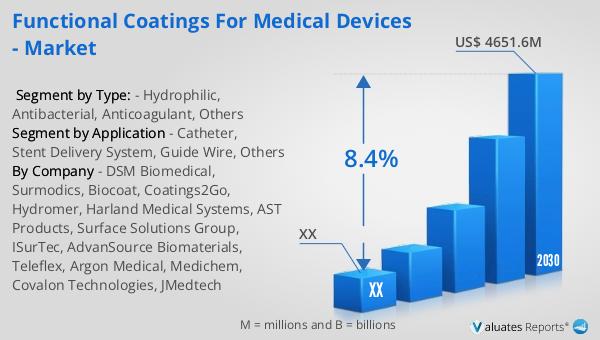

The global market for functional coatings for medical devices was valued at approximately USD 2,751 million in 2023. It is projected to grow to a revised size of USD 4,651.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 8.4% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for advanced medical devices that offer enhanced performance and safety features. The broader medical device market, estimated at USD 603 billion in 2023, is also expected to grow at a CAGR of 5% over the next six years. This expansion is driven by factors such as the rising prevalence of chronic diseases, an aging global population, and the growing adoption of minimally invasive surgical procedures. As healthcare systems worldwide strive for better patient outcomes and cost efficiency, the adoption of functional coatings in medical devices is expected to rise, making it a vital component of the medical device industry. The continuous innovation in coating materials and application techniques will further propel the market, ensuring that medical devices meet the evolving needs of healthcare providers and patients alike.

| Report Metric | Details |

| Report Name | Functional Coatings for Medical Devices - Market |

| Forecasted market size in 2030 | US$ 4651.6 million |

| CAGR | 8.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | DSM Biomedical, Surmodics, Biocoat, Coatings2Go, Hydromer, Harland Medical Systems, AST Products, Surface Solutions Group, ISurTec, AdvanSource Biomaterials, Teleflex, Argon Medical, Medichem, Covalon Technologies, JMedtech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |