What is Food Irradiation Sterilization Equipment - Global Market?

Food irradiation sterilization equipment is a crucial component in the global market, designed to enhance food safety and extend shelf life by using ionizing radiation to eliminate bacteria, parasites, and other pathogens. This technology is particularly significant in the food industry as it helps in reducing the risk of foodborne illnesses and spoilage without compromising nutritional quality or taste. The equipment operates by exposing food products to controlled doses of radiation, which effectively sterilizes them by disrupting the DNA of harmful microorganisms. As consumer awareness about food safety increases, the demand for such equipment is on the rise, driving innovation and adoption across various regions. The global market for food irradiation sterilization equipment is expanding, with advancements in technology making the process more efficient and cost-effective. This growth is supported by regulatory approvals and endorsements from health organizations, which recognize the benefits of irradiation in maintaining food quality and safety. As a result, food irradiation sterilization equipment is becoming an integral part of modern food processing and preservation strategies, catering to the needs of both manufacturers and consumers who prioritize health and safety.

Electron Beam Radiation, Gamma Radiation, X-Ray Radiation in the Food Irradiation Sterilization Equipment - Global Market:

Electron beam radiation, gamma radiation, and X-ray radiation are three primary methods used in food irradiation sterilization equipment, each with unique characteristics and applications in the global market. Electron beam radiation, or e-beam, utilizes high-energy electrons to sterilize food products. This method is known for its speed and efficiency, as it requires only a few seconds of exposure to achieve the desired level of sterilization. E-beam radiation is particularly effective for surface sterilization and is commonly used for products like spices, grains, and certain packaged foods. Its ability to penetrate only a few centimeters into the product makes it ideal for thin or surface-level applications, reducing the risk of altering the food's texture or flavor. Additionally, e-beam equipment is often more compact and cost-effective compared to other irradiation methods, making it an attractive option for many food processors.

Online Sales, Offline Sales in the Food Irradiation Sterilization Equipment - Global Market:

Gamma radiation, on the other hand, employs gamma rays emitted from radioactive isotopes such as Cobalt-60 or Cesium-137. This method is highly effective for deep penetration, allowing it to sterilize bulkier or denser food products, including meats, fruits, and vegetables. Gamma radiation is renowned for its ability to uniformly treat products, ensuring comprehensive sterilization throughout the entire item. This makes it particularly useful for products that require thorough treatment to eliminate pathogens. However, the use of radioactive isotopes necessitates stringent safety measures and regulatory compliance, which can increase operational costs and complexity. Despite these challenges, gamma radiation remains a popular choice due to its proven efficacy and reliability in sterilizing a wide range of food products.

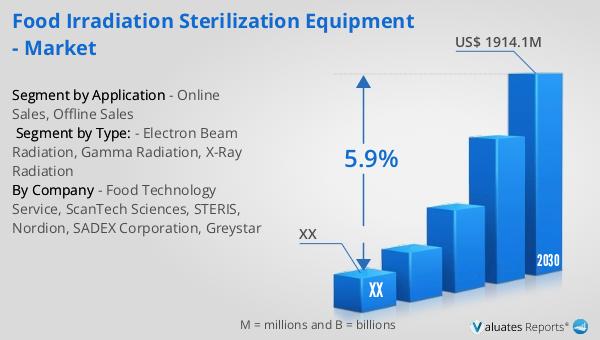

Food Irradiation Sterilization Equipment - Global Market Outlook:

X-ray radiation combines the benefits of both e-beam and gamma radiation, offering deep penetration similar to gamma rays but without the need for radioactive materials. X-ray equipment generates radiation by converting high-energy electrons into X-rays, which can penetrate thick or dense products effectively. This method is versatile and can be used for a variety of food items, including those that are packaged or in bulk. X-ray radiation is particularly advantageous for its safety profile, as it does not involve handling radioactive substances, thereby reducing regulatory burdens and potential risks. Additionally, X-ray systems can be turned on and off as needed, providing greater control and flexibility in the sterilization process. While the initial investment for X-ray equipment can be higher, its operational benefits and safety advantages make it an appealing option for many food processors looking to enhance their sterilization capabilities.

| Report Metric | Details |

| Report Name | Food Irradiation Sterilization Equipment - Market |

| Forecasted market size in 2030 | US$ 1914.1 million |

| CAGR | 5.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Food Technology Service, ScanTech Sciences, STERIS, Nordion, SADEX Corporation, Greystar |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |