What is Drilling Blowout Preventer - Global Market?

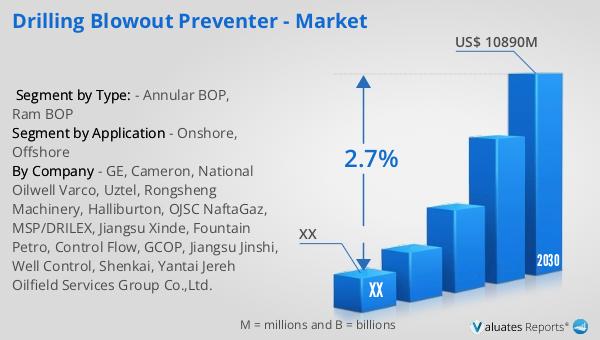

Drilling Blowout Preventers (BOPs) are critical safety devices used in the oil and gas industry to prevent uncontrolled release of crude oil or natural gas from a well. These devices are essential for maintaining control over well pressure during drilling operations, thereby preventing blowouts, which can lead to catastrophic environmental and economic consequences. The global market for Drilling Blowout Preventers is driven by the increasing demand for energy, which necessitates extensive drilling activities both onshore and offshore. As of 2023, the market was valued at approximately US$ 9064.9 million, with projections indicating a growth to US$ 10890 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.7% from 2024 to 2030. This growth is fueled by technological advancements in drilling equipment, stringent safety regulations, and the expansion of exploration activities in untapped regions. The North American market, in particular, plays a significant role in this growth trajectory, driven by its robust oil and gas industry and the adoption of advanced drilling technologies. The market dynamics are influenced by factors such as fluctuating oil prices, regulatory changes, and the increasing focus on sustainable and safe drilling practices.

Annular BOP, Ram BOP in the Drilling Blowout Preventer - Global Market:

Annular BOPs and Ram BOPs are two primary types of blowout preventers used in drilling operations, each serving distinct functions and offering unique advantages. Annular BOPs are designed to seal around the drill pipe, casing, or even an open hole, providing a versatile sealing mechanism that can accommodate various sizes and shapes. This flexibility makes annular BOPs particularly valuable in situations where the drill string's diameter may vary or when dealing with irregular formations. They operate by using a rubber sealing element that is compressed to form a seal, effectively controlling well pressure and preventing blowouts. On the other hand, Ram BOPs use steel rams to seal the wellbore. These rams can be configured in different ways, such as pipe rams, blind rams, or shear rams, each serving a specific purpose. Pipe rams close around the drill pipe, blind rams seal an open wellbore, and shear rams are capable of cutting through the drill pipe to seal the well completely. The choice between annular and ram BOPs depends on the specific requirements of the drilling operation, including the type of well, expected pressures, and the nature of the formations being drilled. In the global market, the demand for these BOPs is influenced by factors such as the complexity of drilling operations, the depth of wells, and the regulatory environment. Technological advancements have led to the development of more efficient and reliable BOPs, enhancing their performance and safety features. For instance, modern BOPs are equipped with advanced monitoring systems that provide real-time data on well conditions, enabling operators to make informed decisions and respond swiftly to any anomalies. The integration of digital technologies and automation in BOP systems is also contributing to market growth, as these innovations improve operational efficiency and reduce the risk of human error. Furthermore, the increasing focus on environmental protection and safety in drilling operations is driving the adoption of high-performance BOPs that meet stringent regulatory standards. As the oil and gas industry continues to explore deeper and more challenging reservoirs, the demand for robust and reliable BOPs is expected to rise, supporting the overall growth of the global market.

Onshore, Offshore in the Drilling Blowout Preventer - Global Market:

The usage of Drilling Blowout Preventers in onshore and offshore drilling operations is crucial for ensuring safety and operational efficiency. Onshore drilling, which involves extracting oil and gas from land-based wells, relies heavily on BOPs to manage well pressure and prevent blowouts. These devices are installed at the wellhead and are essential for maintaining control over the drilling process, especially in high-pressure formations. Onshore drilling operations often face challenges such as varying geological conditions and the presence of multiple layers of rock, which can lead to unexpected pressure changes. BOPs play a vital role in mitigating these risks by providing a reliable sealing mechanism that can be activated quickly in case of a pressure surge. Offshore drilling, on the other hand, involves extracting oil and gas from beneath the ocean floor, presenting unique challenges due to the harsh marine environment and the complexity of deepwater operations. In offshore drilling, BOPs are typically installed on the seabed, known as subsea BOPs, and are connected to the drilling rig via a riser system. These BOPs must withstand extreme pressures and temperatures, as well as the corrosive effects of seawater. The use of BOPs in offshore drilling is critical for preventing blowouts, which can have devastating environmental impacts and pose significant risks to human safety. The global market for drilling blowout preventers is driven by the increasing demand for energy and the expansion of exploration activities in both onshore and offshore regions. Technological advancements in BOP design and materials have led to the development of more robust and reliable devices, capable of withstanding the challenging conditions encountered in modern drilling operations. The integration of digital technologies and automation in BOP systems is also enhancing their performance, providing operators with real-time data on well conditions and enabling swift responses to any anomalies. As the oil and gas industry continues to push the boundaries of exploration and production, the demand for high-performance BOPs is expected to grow, supporting the overall expansion of the global market.

Drilling Blowout Preventer - Global Market Outlook:

The global market for Drilling Blowout Preventers was valued at approximately US$ 9064.9 million in 2023, with expectations to reach a revised size of US$ 10890 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.7% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for energy and the expansion of drilling activities worldwide. The North American market, in particular, is a significant contributor to this growth, driven by its well-established oil and gas industry and the adoption of advanced drilling technologies. Although specific figures for the North American market were not provided, it is anticipated to follow a similar growth trajectory, supported by factors such as technological advancements, regulatory changes, and the increasing focus on sustainable and safe drilling practices. The market dynamics are influenced by various factors, including fluctuating oil prices, the development of new oil and gas reserves, and the implementation of stringent safety regulations. As the industry continues to evolve, the demand for reliable and efficient blowout preventers is expected to rise, supporting the overall growth of the global market.

| Report Metric | Details |

| Report Name | Drilling Blowout Preventer - Market |

| Forecasted market size in 2030 | US$ 10890 million |

| CAGR | 2.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | GE, Cameron, National Oilwell Varco, Uztel, Rongsheng Machinery, Halliburton, OJSC NaftaGaz, MSP/DRILEX, Jiangsu Xinde, Fountain Petro, Control Flow, GCOP, Jiangsu Jinshi, Well Control, Shenkai, Yantai Jereh Oilfield Services Group Co.,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |