What is Automatic Winding Machine - Global Market?

The Automatic Winding Machine is a crucial component in the textile and garment industries, designed to wind yarn or thread onto a spool or bobbin efficiently. This machine automates the winding process, which traditionally required manual labor, thereby increasing productivity and reducing human error. The global market for Automatic Winding Machines is expanding due to the growing demand for textiles and garments worldwide. These machines are essential for ensuring that yarns are wound uniformly, which is critical for the quality of the final textile product. They come equipped with advanced features such as tension control, yarn breakage detection, and automatic doffing, which further enhance their efficiency and reliability. The market is driven by technological advancements and the increasing adoption of automation in manufacturing processes. As industries strive for higher efficiency and lower operational costs, the demand for Automatic Winding Machines is expected to grow, making them a vital part of the textile manufacturing landscape.

Semi-Automatic, Fully-Automatic in the Automatic Winding Machine - Global Market:

In the realm of Automatic Winding Machines, there are two primary types: Semi-Automatic and Fully-Automatic. Semi-Automatic Winding Machines require some level of human intervention. Operators are needed to load the yarn and initiate the winding process. These machines are generally more affordable and are suitable for smaller operations or businesses that do not require high-speed production. They offer a balance between automation and manual control, allowing operators to oversee the process and make adjustments as needed. This type of machine is ideal for businesses that are transitioning from manual to automated processes, providing a stepping stone towards full automation. On the other hand, Fully-Automatic Winding Machines are designed to operate with minimal human intervention. These machines are equipped with advanced sensors and control systems that manage the entire winding process, from loading the yarn to winding it onto the bobbin and even replacing the bobbin when it is full. Fully-Automatic machines are perfect for large-scale operations where speed and efficiency are paramount. They significantly reduce labor costs and increase production rates, making them a preferred choice for large textile manufacturers. The choice between Semi-Automatic and Fully-Automatic machines depends largely on the scale of production and the specific needs of the business. While Semi-Automatic machines offer flexibility and lower initial costs, Fully-Automatic machines provide unmatched efficiency and productivity. As the global market for Automatic Winding Machines continues to grow, manufacturers are focusing on developing machines that offer greater precision, speed, and reliability. Innovations in technology are leading to the creation of machines that can handle a wider range of yarn types and sizes, further expanding their applicability in the textile industry. The demand for these machines is also influenced by the increasing emphasis on sustainability and energy efficiency. Manufacturers are now producing machines that consume less power and produce less waste, aligning with global efforts to reduce the environmental impact of industrial processes. In conclusion, both Semi-Automatic and Fully-Automatic Winding Machines play a vital role in the textile industry, each catering to different needs and scales of operation. As technology continues to advance, these machines are becoming more sophisticated, offering enhanced features that improve the quality and efficiency of textile production.

Cotton Mill, Garment Factory, Others in the Automatic Winding Machine - Global Market:

Automatic Winding Machines are extensively used in various sectors, including Cotton Mills, Garment Factories, and other industries that require precise winding of yarns or threads. In Cotton Mills, these machines are indispensable. They ensure that the yarn produced from raw cotton is wound uniformly onto spools, which is crucial for the subsequent weaving or knitting processes. The uniformity in winding helps in maintaining the quality of the fabric, reducing defects, and ensuring smooth operation of looms. In Garment Factories, Automatic Winding Machines play a critical role in preparing threads for sewing and embroidery. The machines ensure that the threads are wound with consistent tension and length, which is essential for high-quality garment production. This consistency helps in reducing thread breakage during sewing, leading to fewer interruptions and higher productivity. Additionally, these machines can handle a variety of thread types, including those used for decorative stitching, making them versatile tools in garment manufacturing. Beyond Cotton Mills and Garment Factories, Automatic Winding Machines find applications in other industries such as electronics, where they are used to wind wires and cables. In the electronics industry, precision is key, and these machines provide the accuracy needed for winding delicate wires used in components like transformers and inductors. The ability to control tension and speed ensures that the wires are wound without damage, maintaining the integrity of the electronic components. Furthermore, the use of Automatic Winding Machines extends to the production of fishing lines, ropes, and even in the medical field for winding surgical sutures. The versatility of these machines makes them valuable across various sectors, contributing to improved efficiency and product quality. As industries continue to evolve, the demand for Automatic Winding Machines is expected to rise, driven by the need for automation and precision in manufacturing processes.

Automatic Winding Machine - Global Market Outlook:

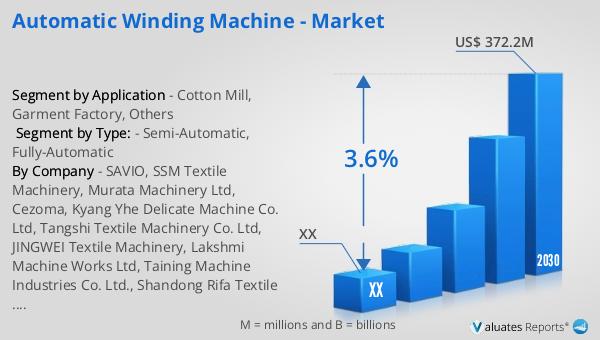

The global market for Automatic Winding Machines was valued at approximately US$ 283 million in 2023. It is projected to grow to a revised size of US$ 372.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.6% during the forecast period from 2024 to 2030. This growth is indicative of the increasing adoption of automation in the textile and garment industries, as well as other sectors that require precise winding solutions. The market's expansion is supported by technological advancements and the rising demand for high-quality textile products. In a related note, the construction machinery sector in Europe saw a significant increase in sales, with a 24% rise in 2021. By 2022, the revenue from construction machinery in Europe reached approximately US$ 22 billion. Meanwhile, the United States market reported sales of about US$ 36 billion in construction machinery in 2022. These figures highlight the broader trend of automation and machinery adoption across various industries, underscoring the importance of technological innovation in driving market growth. As industries continue to seek efficiency and cost-effectiveness, the demand for advanced machinery, including Automatic Winding Machines, is expected to remain strong.

| Report Metric | Details |

| Report Name | Automatic Winding Machine - Market |

| Forecasted market size in 2030 | US$ 372.2 million |

| CAGR | 3.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | SAVIO, SSM Textile Machinery, Murata Machinery Ltd, Cezoma, Kyang Yhe Delicate Machine Co. Ltd, Tangshi Textile Machinery Co. Ltd, JINGWEI Textile Machinery, Lakshmi Machine Works Ltd, Taining Machine Industries Co. Ltd., Shandong Rifa Textile Machinery Co., Ltd., Weavetech, Schlafhors, QingDao HongDA Textile Machinery Co.,LTD, Thread Master, Veejay Lakshmi Engineering Works.., Xinghua Tangshi Textile Machinery, ZHEJIANG KAICHENG INTELLIGENT MACHINERY CO., LTD. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |