What is Automatic Ultrasonic Flaw Detector - Global Market?

Automatic Ultrasonic Flaw Detectors are sophisticated devices used in various industries to identify defects or irregularities within materials without causing any damage. These detectors employ high-frequency sound waves to penetrate materials and detect flaws such as cracks, voids, or inclusions. The global market for these devices is expanding due to the increasing demand for non-destructive testing methods across industries like energy, aerospace, oil and gas, and automotive. The technology is favored for its precision, efficiency, and ability to provide real-time results, which are crucial for maintaining safety and quality standards. As industries continue to prioritize safety and quality, the demand for automatic ultrasonic flaw detectors is expected to grow, driven by advancements in technology and the need for more reliable testing methods. The market is characterized by a mix of established players and new entrants, each contributing to the innovation and development of more advanced and user-friendly devices.

Portable, Benchtop in the Automatic Ultrasonic Flaw Detector - Global Market:

The global market for automatic ultrasonic flaw detectors is diverse, with devices available in both portable and benchtop configurations. Portable ultrasonic flaw detectors are designed for ease of use and mobility, making them ideal for field inspections and on-site testing. These devices are compact, lightweight, and often battery-operated, allowing technicians to carry them to various locations without hassle. They are equipped with user-friendly interfaces and advanced features such as digital displays, data storage, and wireless connectivity, enabling seamless data transfer and analysis. Portable detectors are particularly useful in industries where testing needs to be conducted in remote or hard-to-reach areas, such as pipelines in the oil and gas sector or aircraft components in the aerospace industry. On the other hand, benchtop ultrasonic flaw detectors are typically used in laboratory or manufacturing settings where more comprehensive testing is required. These devices are larger and more robust, offering higher precision and a wider range of testing capabilities. They are often integrated into automated testing systems, providing continuous monitoring and analysis of materials during production processes. Benchtop detectors are favored in industries where high-volume testing is necessary, such as automotive manufacturing or energy production. Both portable and benchtop ultrasonic flaw detectors play a crucial role in ensuring the integrity and safety of materials and structures. They help identify potential issues before they become critical, reducing the risk of failures and accidents. The choice between portable and benchtop detectors depends on the specific needs of the industry and the nature of the testing required. As technology continues to evolve, both types of detectors are becoming more advanced, with features such as enhanced imaging capabilities, improved data analysis tools, and greater connectivity options. This evolution is driving the growth of the global market for automatic ultrasonic flaw detectors, as industries seek more efficient and reliable testing solutions.

Energy, Aerospace, Oil & Gas, Automotive, Others in the Automatic Ultrasonic Flaw Detector - Global Market:

Automatic ultrasonic flaw detectors are widely used across various industries due to their ability to provide accurate and non-invasive testing. In the energy sector, these detectors are essential for inspecting critical infrastructure such as pipelines, turbines, and reactors. They help identify potential defects that could lead to failures or inefficiencies, ensuring the safe and reliable operation of energy systems. In the aerospace industry, ultrasonic flaw detectors are used to inspect aircraft components, including wings, fuselage, and engines. The high precision of these devices is crucial for detecting even the smallest defects that could compromise the safety and performance of aircraft. In the oil and gas industry, ultrasonic flaw detectors are used to inspect pipelines, storage tanks, and other critical infrastructure. They help prevent leaks and spills by identifying potential weaknesses before they become problematic. In the automotive industry, these detectors are used to inspect components such as engine parts, chassis, and suspension systems. They ensure that vehicles meet safety and quality standards by detecting defects that could affect performance or durability. Beyond these industries, ultrasonic flaw detectors are also used in sectors such as construction, manufacturing, and railways. They are employed to inspect structures, machinery, and equipment, ensuring their integrity and safety. The versatility and reliability of automatic ultrasonic flaw detectors make them an indispensable tool for maintaining safety and quality across various industries. As the demand for non-destructive testing continues to grow, the usage of these detectors is expected to expand further, driven by advancements in technology and the increasing need for efficient and reliable testing solutions.

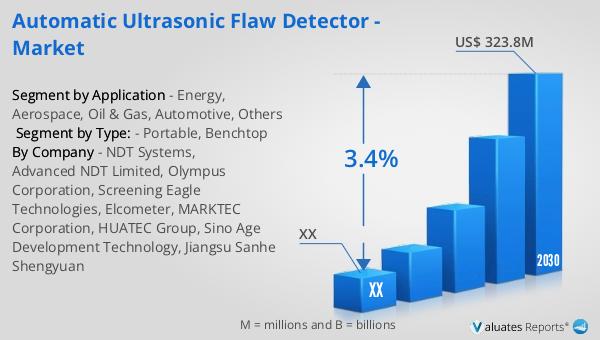

Automatic Ultrasonic Flaw Detector - Global Market Outlook:

The global market for automatic ultrasonic flaw detectors was valued at approximately $255 million in 2023. It is projected to grow to a revised size of $323.8 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for non-destructive testing methods across various industries, including energy, aerospace, oil and gas, and automotive. The market is dominated by a few key players, with the top five manufacturers accounting for over 54% of the global market share. These leading companies are at the forefront of innovation, continuously developing more advanced and user-friendly devices to meet the evolving needs of their customers. The competitive landscape of the market is characterized by a mix of established players and new entrants, each contributing to the development of more efficient and reliable testing solutions. As industries continue to prioritize safety and quality, the demand for automatic ultrasonic flaw detectors is expected to grow, driven by advancements in technology and the need for more reliable testing methods. The market is poised for steady growth, with opportunities for both existing players and new entrants to capitalize on the increasing demand for non-destructive testing solutions.

| Report Metric | Details |

| Report Name | Automatic Ultrasonic Flaw Detector - Market |

| Forecasted market size in 2030 | US$ 323.8 million |

| CAGR | 3.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | NDT Systems, Advanced NDT Limited, Olympus Corporation, Screening Eagle Technologies, Elcometer, MARKTEC Corporation, HUATEC Group, Sino Age Development Technology, Jiangsu Sanhe Shengyuan |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |