What is AOI for Flexible OLED Displays - Global Market?

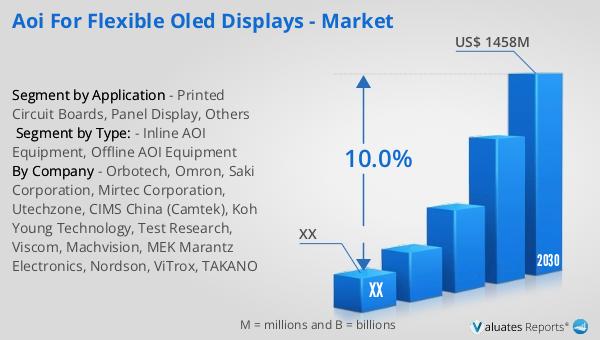

The global market for Automated Optical Inspection (AOI) systems specifically designed for Flexible OLED Displays is experiencing significant growth. In 2023, the market was valued at approximately US$ 758 million, and it is projected to expand to a size of US$ 1458 million by 2030, reflecting a compound annual growth rate (CAGR) of 10.0% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-quality flexible OLED displays, which are used in a variety of applications such as smartphones, tablets, and wearable devices. The North American market, in particular, is poised for substantial growth, although specific figures for this region were not provided. The adoption of AOI systems in this sector is crucial as they ensure the quality and reliability of OLED displays by detecting defects and inconsistencies during the manufacturing process. As the technology continues to evolve, manufacturers are increasingly investing in advanced AOI systems to maintain competitive advantage and meet the stringent quality standards required by consumers and industries alike. This trend underscores the importance of AOI systems in the flexible OLED display market, highlighting their role in enhancing production efficiency and product quality.

Inline AOI Equipment, Offline AOI Equipment in the AOI for Flexible OLED Displays - Global Market:

Inline AOI equipment and offline AOI equipment are two critical components in the AOI for Flexible OLED Displays market. Inline AOI equipment is integrated directly into the production line, allowing for real-time inspection of OLED displays as they are being manufactured. This type of equipment is essential for maintaining a continuous flow of production, as it can quickly identify and address defects without halting the manufacturing process. Inline AOI systems are equipped with high-speed cameras and advanced image processing software that can detect minute defects in the displays, such as pixel defects, alignment issues, and surface irregularities. By providing immediate feedback, these systems enable manufacturers to make necessary adjustments on the fly, thereby reducing waste and improving overall production efficiency. On the other hand, offline AOI equipment is used for post-production inspection. These systems are typically employed in quality control departments where finished products are thoroughly examined before being shipped to customers. Offline AOI equipment offers a more detailed analysis of the displays, as they are not constrained by the speed of the production line. This allows for a more comprehensive inspection, ensuring that only the highest quality products reach the market. Both inline and offline AOI systems play a crucial role in the flexible OLED display manufacturing process, each offering unique advantages that contribute to the overall quality and reliability of the final product. As the demand for flexible OLED displays continues to rise, manufacturers are increasingly investing in both types of AOI equipment to ensure they meet the high standards expected by consumers and industries. The integration of these systems into the production process not only enhances product quality but also improves operational efficiency, making them indispensable tools in the competitive OLED display market.

Printed Circuit Boards, Panel Display, Others in the AOI for Flexible OLED Displays - Global Market:

The usage of AOI systems in the flexible OLED displays market extends across various areas, including printed circuit boards (PCBs), panel displays, and other related components. In the context of printed circuit boards, AOI systems are employed to inspect the intricate circuitry that forms the backbone of OLED displays. These systems are capable of detecting defects such as open circuits, short circuits, and misalignments, which can significantly impact the performance and reliability of the final product. By ensuring the integrity of the PCBs, AOI systems help manufacturers maintain high-quality standards and reduce the risk of product failures. In panel displays, AOI systems are used to inspect the surface and structural integrity of the OLED panels. This includes checking for defects such as scratches, blemishes, and pixel inconsistencies that can affect the visual quality of the display. The ability to identify and rectify these issues early in the production process is crucial for manufacturers aiming to deliver flawless products to the market. Additionally, AOI systems are used in other areas such as the inspection of flexible substrates and encapsulation layers, which are essential components of flexible OLED displays. These systems ensure that each layer is free from defects and properly aligned, contributing to the overall durability and performance of the display. The comprehensive inspection capabilities of AOI systems make them indispensable in the production of flexible OLED displays, as they help manufacturers achieve the high-quality standards demanded by consumers and industries. By integrating AOI systems into their production processes, manufacturers can enhance product quality, reduce waste, and improve operational efficiency, ultimately leading to greater customer satisfaction and competitive advantage in the market.

AOI for Flexible OLED Displays - Global Market Outlook:

English: #FlexibleOLED #AOIMarket #DisplayTechnology #Innovation #QualityControl #Manufacturing #TechTrends #GlobalMarket #OLEDDisplays #InspectionSystems

| Report Metric | Details |

| Report Name | AOI for Flexible OLED Displays - Market |

| Forecasted market size in 2030 | US$ 1458 million |

| CAGR | 10.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Orbotech, Omron, Saki Corporation, Mirtec Corporation, Utechzone, CIMS China (Camtek), Koh Young Technology, Test Research, Viscom, Machvision, MEK Marantz Electronics, Nordson, ViTrox, TAKANO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |