What is VCI Aerosols - Global Market?

VCI Aerosols, or Vapor Corrosion Inhibitor Aerosols, are specialized products designed to protect metal surfaces from corrosion. These aerosols release a vapor that forms a protective molecular layer on metal surfaces, preventing moisture and other corrosive elements from causing damage. The global market for VCI Aerosols is driven by the increasing demand for effective corrosion protection solutions across various industries. As metals are integral to numerous applications, from automotive to electronics, the need to preserve their integrity during storage and transportation is paramount. VCI Aerosols offer a convenient and efficient way to safeguard metal components without the need for extensive packaging or coatings. Their ease of application and effectiveness make them a preferred choice for industries looking to extend the lifespan of their metal products. The market's growth is further fueled by advancements in aerosol technology, which enhance the delivery and performance of these corrosion inhibitors. As industries continue to prioritize the longevity and reliability of their metal assets, the demand for VCI Aerosols is expected to rise, reflecting a broader trend towards sustainable and cost-effective corrosion protection solutions.

Organic, Inorganic in the VCI Aerosols - Global Market:

In the realm of VCI Aerosols, the distinction between organic and inorganic compounds plays a crucial role in determining their effectiveness and application. Organic VCI Aerosols are primarily composed of carbon-based compounds. These compounds are known for their ability to form a protective barrier on metal surfaces, effectively preventing the onset of corrosion. Organic inhibitors are often favored for their environmental friendliness and biodegradability, making them a popular choice in industries that prioritize sustainability. They work by adsorbing onto the metal surface, creating a thin film that repels moisture and other corrosive agents. This type of VCI is particularly effective in environments where metals are exposed to fluctuating humidity levels and temperatures, as the organic compounds can adapt to changing conditions, maintaining their protective qualities. On the other hand, inorganic VCI Aerosols are composed of mineral-based compounds. These inhibitors are typically more robust and can offer longer-lasting protection compared to their organic counterparts. Inorganic VCIs work by forming a passive layer on the metal surface, which acts as a barrier against corrosive elements. This type of VCI is often used in more aggressive environments where metals are exposed to harsh chemicals or extreme weather conditions. The inorganic compounds provide a stable and durable protective layer, ensuring the metal remains unscathed over extended periods. While inorganic VCIs may not be as environmentally friendly as organic ones, their effectiveness in challenging conditions makes them indispensable in certain applications. The choice between organic and inorganic VCI Aerosols largely depends on the specific requirements of the application, including environmental considerations, the nature of the metal being protected, and the conditions to which it will be exposed. Both types of VCIs have their unique advantages and limitations, and understanding these can help industries make informed decisions about the most suitable corrosion protection strategy. As the global market for VCI Aerosols continues to expand, the development of hybrid solutions that combine the benefits of both organic and inorganic compounds is also gaining traction. These hybrid aerosols aim to offer the best of both worlds, providing robust protection while minimizing environmental impact. The ongoing research and innovation in this field are expected to lead to more advanced and versatile VCI solutions, catering to the diverse needs of industries worldwide.

Oil & Gas, Power Generation, Paper & Pulp, Metal Processing, Chemical Processing, Water Treatment, Others in the VCI Aerosols - Global Market:

VCI Aerosols find extensive usage across various industries due to their effective corrosion protection capabilities. In the oil and gas sector, these aerosols are crucial for safeguarding metal components used in exploration, drilling, and transportation. The harsh environments and exposure to corrosive substances in this industry necessitate reliable protection to ensure the longevity and functionality of equipment. VCI Aerosols provide a convenient solution, allowing for easy application and consistent protection even in remote locations. Similarly, in the power generation industry, VCI Aerosols play a vital role in maintaining the integrity of metal components used in turbines, generators, and other critical infrastructure. The constant exposure to moisture and varying temperatures can lead to corrosion, which can compromise the efficiency and safety of power generation facilities. By using VCI Aerosols, operators can ensure that their equipment remains in optimal condition, reducing maintenance costs and downtime. In the paper and pulp industry, metal machinery and components are often exposed to humid and corrosive environments. VCI Aerosols help protect these assets, ensuring smooth operations and preventing costly repairs or replacements. The metal processing industry also benefits significantly from VCI Aerosols, as they provide an effective means of protecting raw materials and finished products during storage and transportation. This is particularly important in maintaining the quality and appearance of metal goods, which can be adversely affected by corrosion. In chemical processing, where metal equipment is frequently exposed to aggressive chemicals, VCI Aerosols offer a reliable barrier against corrosion, extending the lifespan of machinery and reducing the risk of contamination. Water treatment facilities also utilize VCI Aerosols to protect metal components from the corrosive effects of water and chemicals used in the treatment process. This ensures the longevity and efficiency of the treatment systems, contributing to the overall effectiveness of water purification efforts. Beyond these specific industries, VCI Aerosols are used in various other sectors where metal corrosion is a concern. Their versatility and ease of use make them an attractive option for any application where metal preservation is critical. As industries continue to seek cost-effective and efficient corrosion protection solutions, the demand for VCI Aerosols is expected to grow, reflecting their importance in maintaining the integrity and performance of metal assets.

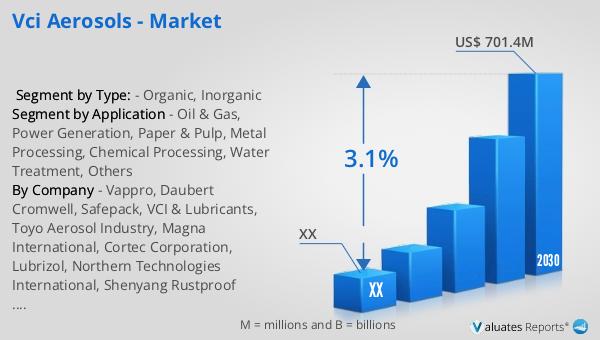

VCI Aerosols - Global Market Outlook:

The global market for VCI Aerosols was valued at approximately $567 million in 2023. It is projected to grow to around $701.4 million by 2030, with a compound annual growth rate (CAGR) of 3.1% during the forecast period from 2024 to 2030. This growth is indicative of the increasing recognition of the importance of effective corrosion protection for metal components across various industries. As industries become more aware of the potential costs and operational disruptions caused by corrosion, the demand for reliable and efficient solutions like VCI Aerosols is on the rise. The global expansion of the VCI Aerosols market is driven by the need to protect metal assets during storage and transportation, ensuring their longevity and performance. This trend is particularly evident in sectors such as automotive, aerospace, and manufacturing, where the integrity of metal components is crucial to operational success. The convenience and effectiveness of VCI Aerosols make them a preferred choice for industries looking to minimize maintenance costs and extend the lifespan of their metal products. As the market continues to grow, advancements in aerosol technology and the development of more environmentally friendly formulations are expected to further enhance the appeal and adoption of VCI Aerosols worldwide.

| Report Metric | Details |

| Report Name | VCI Aerosols - Market |

| Forecasted market size in 2030 | US$ 701.4 million |

| CAGR | 3.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Vappro, Daubert Cromwell, Safepack, VCI & Lubricants, Toyo Aerosol Industry, Magna International, Cortec Corporation, Lubrizol, Northern Technologies International, Shenyang Rustproof Packaging Material, Whitebird, Rustx |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |