What is Steel Sucker Rod - Global Market?

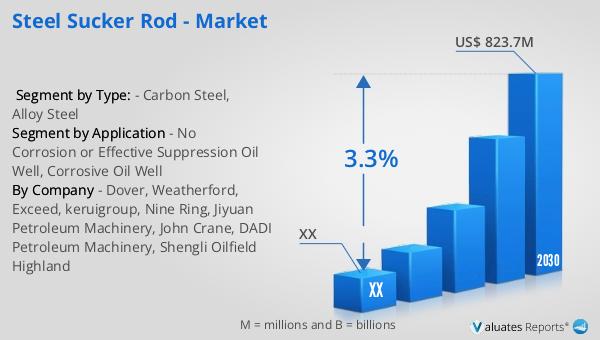

Steel sucker rods are essential components in the oil and gas industry, specifically designed for the artificial lifting of fluids such as crude oil and natural gas from wells. These rods are part of a larger system known as the sucker rod pump, which is used to extract oil from wells that do not have enough pressure to push the oil to the surface naturally. The global market for steel sucker rods was valued at approximately US$ 658.4 million in 2023. This market is projected to grow to a revised size of US$ 823.7 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.3% during the forecast period from 2024 to 2030. The growth in this market can be attributed to the increasing demand for energy and the need for efficient extraction methods in the oil and gas sector. Steel sucker rods are favored for their durability and strength, which are crucial for withstanding the harsh conditions often encountered in oil wells. As the energy sector continues to evolve, the demand for reliable and efficient extraction tools like steel sucker rods is expected to remain strong.

Carbon Steel, Alloy Steel in the Steel Sucker Rod - Global Market:

Steel sucker rods are primarily made from two types of steel: carbon steel and alloy steel. Carbon steel sucker rods are widely used due to their cost-effectiveness and adequate performance in standard oil well conditions. Carbon steel is composed mainly of iron and carbon, with the carbon content typically ranging from 0.05% to 2.0%. This composition provides a good balance of strength and ductility, making carbon steel sucker rods suitable for many oil extraction applications. However, carbon steel rods are more susceptible to corrosion, which can be a significant drawback in certain environments. To mitigate this, carbon steel rods are often coated or treated with corrosion-resistant materials to extend their lifespan and maintain their performance in corrosive environments. On the other hand, alloy steel sucker rods are engineered to offer enhanced performance characteristics, particularly in challenging oil well conditions. Alloy steel is made by adding various alloying elements such as chromium, nickel, and molybdenum to the base iron-carbon mix. These elements improve the mechanical properties of the steel, such as its strength, toughness, and resistance to wear and corrosion. Alloy steel sucker rods are particularly beneficial in wells with high temperatures, pressures, or corrosive elements, where standard carbon steel rods might fail. The choice between carbon steel and alloy steel sucker rods depends largely on the specific conditions of the oil well and the cost considerations of the operation. While alloy steel rods offer superior performance, they are also more expensive than their carbon steel counterparts. Therefore, operators must weigh the benefits of enhanced durability and resistance against the higher initial investment. In the global market, the demand for both carbon steel and alloy steel sucker rods is influenced by factors such as the geographical location of oil fields, the depth and pressure of wells, and the presence of corrosive elements. As oil extraction technology advances and the industry faces new challenges, the development and adoption of more sophisticated materials for sucker rods are likely to continue. This ongoing evolution in materials science and engineering is crucial for meeting the growing energy demands while ensuring the safety and efficiency of oil extraction processes.

No Corrosion or Effective Suppression Oil Well, Corrosive Oil Well in the Steel Sucker Rod - Global Market:

Steel sucker rods play a crucial role in the oil and gas industry, particularly in environments where corrosion is a significant concern. In non-corrosive or effectively suppressed oil wells, steel sucker rods are used to lift fluids efficiently without the added worry of rapid degradation due to corrosion. These environments are typically characterized by the absence or minimal presence of corrosive agents such as hydrogen sulfide or carbon dioxide, which can cause significant damage to steel components. In such settings, standard carbon steel sucker rods are often sufficient, providing a cost-effective solution for oil extraction. However, even in non-corrosive environments, operators may choose to use alloy steel sucker rods for their enhanced mechanical properties and longer lifespan, which can lead to reduced maintenance costs and downtime. In contrast, corrosive oil wells present a more challenging environment for steel sucker rods. These wells contain corrosive agents that can significantly reduce the lifespan of standard carbon steel rods, leading to frequent replacements and increased operational costs. To combat this, operators often opt for alloy steel sucker rods, which are designed to withstand the harsh conditions of corrosive wells. The alloying elements in these rods, such as chromium and nickel, provide a protective barrier against corrosion, ensuring the rods maintain their structural integrity over time. Additionally, various coatings and treatments can be applied to steel sucker rods to further enhance their resistance to corrosion. These treatments can include processes such as galvanization, where a protective zinc coating is applied, or the use of advanced polymer coatings that provide a barrier against corrosive elements. The choice of material and treatment for steel sucker rods in corrosive oil wells is critical to ensuring the efficiency and safety of oil extraction operations. As the global demand for oil continues to rise, the need for durable and reliable extraction tools becomes increasingly important. The development of advanced materials and coatings for steel sucker rods is a key area of focus for the industry, as it seeks to improve the longevity and performance of these essential components in challenging environments.

Steel Sucker Rod - Global Market Outlook:

The global market for steel sucker rods was valued at approximately US$ 658.4 million in 2023, with projections indicating a growth to US$ 823.7 million by 2030. This anticipated growth reflects a compound annual growth rate (CAGR) of 3.3% during the forecast period from 2024 to 2030. Steel sucker rods are vital components in the oil and gas industry, used primarily for the artificial lifting of fluids such as crude oil and natural gas from wells. These rods are integral to the sucker rod pump system, which is employed in wells that lack sufficient pressure to naturally push oil to the surface. The increasing demand for energy and the need for efficient extraction methods are key drivers of the market's growth. Steel sucker rods are preferred for their durability and strength, essential qualities for withstanding the harsh conditions often encountered in oil wells. As the energy sector continues to evolve, the demand for reliable and efficient extraction tools like steel sucker rods is expected to remain robust, supporting the market's expansion over the coming years.

| Report Metric | Details |

| Report Name | Steel Sucker Rod - Market |

| Forecasted market size in 2030 | US$ 823.7 million |

| CAGR | 3.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Dover, Weatherford, Exceed, keruigroup, Nine Ring, Jiyuan Petroleum Machinery, John Crane, DADI Petroleum Machinery, Shengli Oilfield Highland |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |