What is Plastic Floating Dock - Global Market?

Plastic floating docks are innovative structures designed to provide stable and versatile platforms on water bodies. These docks are made from durable plastic materials, which offer several advantages over traditional wooden or metal docks. The global market for plastic floating docks is expanding due to their increasing popularity in various applications, such as marinas, residential waterfronts, and commercial ports. These docks are modular, allowing for easy customization and expansion to suit specific needs. They are also resistant to corrosion, rot, and UV damage, making them a long-lasting solution for both freshwater and saltwater environments. The ease of installation and maintenance further adds to their appeal, as they require minimal tools and expertise to set up. Additionally, plastic floating docks are environmentally friendly, as they are often made from recycled materials and can be recycled at the end of their lifespan. This sustainable aspect is becoming increasingly important as environmental concerns continue to rise globally. Overall, the plastic floating dock market is poised for growth as more individuals and businesses recognize the benefits of these versatile and durable structures.

PP Type, PET Type, Others in the Plastic Floating Dock - Global Market:

In the realm of plastic floating docks, there are several types of materials used, each offering unique properties and benefits. Among these, Polypropylene (PP) and Polyethylene Terephthalate (PET) are two prominent types, along with other materials that cater to specific needs. Polypropylene, or PP, is a thermoplastic polymer known for its robustness and resistance to various chemical solvents, acids, and bases. This makes PP an ideal choice for floating docks that need to withstand harsh environmental conditions. Its lightweight nature also contributes to easy handling and installation, which is a significant advantage for users looking for a hassle-free setup. Moreover, PP is highly resistant to UV radiation, ensuring that the docks maintain their structural integrity and appearance over time, even when exposed to direct sunlight. This durability is crucial for docks used in regions with high sun exposure, as it prevents degradation and extends the lifespan of the dock. On the other hand, Polyethylene Terephthalate, or PET, is another popular material used in the construction of plastic floating docks. PET is renowned for its strength and rigidity, which provides a stable platform for various activities. Its excellent resistance to water absorption makes it suitable for prolonged use in aquatic environments without the risk of swelling or warping. Additionally, PET is recyclable, aligning with the growing demand for sustainable and eco-friendly products. This characteristic is particularly appealing to environmentally conscious consumers and businesses looking to reduce their carbon footprint. PET's versatility also allows for the creation of aesthetically pleasing designs, as it can be molded into various shapes and sizes to meet specific aesthetic and functional requirements. Apart from PP and PET, other materials are also used in the production of plastic floating docks, each offering distinct advantages. For instance, High-Density Polyethylene (HDPE) is another common choice due to its exceptional strength-to-density ratio. HDPE docks are known for their impact resistance and ability to withstand heavy loads, making them suitable for commercial applications where durability is paramount. Furthermore, HDPE is resistant to mold, mildew, and other biological growth, ensuring that the docks remain clean and safe for use over time. Another material, Polyvinyl Chloride (PVC), is sometimes used for its flexibility and ease of fabrication. PVC docks can be customized to fit unique configurations and are often used in residential settings where specific design requirements are needed. In summary, the choice of material for plastic floating docks depends on various factors, including the intended use, environmental conditions, and aesthetic preferences. PP, PET, and other materials each offer distinct benefits that cater to different needs, making them versatile options for a wide range of applications. As the global market for plastic floating docks continues to grow, the demand for these materials is expected to rise, driven by their durability, sustainability, and adaptability to diverse environments.

Commercial, Residential in the Plastic Floating Dock - Global Market:

Plastic floating docks are utilized in various sectors, with commercial and residential applications being among the most prominent. In commercial settings, these docks serve as essential infrastructure for marinas, ports, and other waterfront businesses. Their modular design allows for easy customization and expansion, accommodating a wide range of vessels and activities. For marinas, plastic floating docks provide a stable and safe platform for docking boats, facilitating smooth operations and enhancing the overall experience for boat owners and visitors. The durability of plastic materials ensures that these docks can withstand the wear and tear of frequent use, reducing maintenance costs and downtime. Additionally, their resistance to corrosion and UV damage makes them ideal for long-term use in harsh marine environments, where traditional materials might fail. In residential areas, plastic floating docks offer homeowners a convenient and attractive solution for accessing water bodies. Whether it's for recreational activities like swimming, fishing, or boating, these docks provide a safe and stable platform for various water-based activities. Their ease of installation and maintenance makes them a popular choice for homeowners looking to enhance their waterfront properties without the hassle of complex construction projects. Moreover, the aesthetic versatility of plastic floating docks allows homeowners to customize their docks to match their personal style and preferences, adding value and appeal to their properties. The environmental benefits of using recycled materials in the construction of these docks also resonate with eco-conscious homeowners, who appreciate the sustainable aspect of their investment. Furthermore, plastic floating docks are increasingly being used in public spaces, such as parks and recreational areas, where they provide access to water for community activities and events. Their adaptability and ease of use make them suitable for temporary installations, such as floating stages or platforms for special events. This versatility is particularly beneficial for municipalities and organizations looking to create dynamic and engaging waterfront spaces without committing to permanent structures. The ability to quickly assemble and disassemble these docks also allows for flexibility in planning and executing events, ensuring that the space can be used for a variety of purposes throughout the year. Overall, the use of plastic floating docks in commercial and residential settings highlights their versatility and practicality. Their durability, ease of installation, and environmental benefits make them an attractive option for a wide range of applications, from enhancing private waterfront properties to supporting commercial operations and public events. As awareness of these benefits continues to grow, the demand for plastic floating docks is expected to increase, further driving innovation and development in this market.

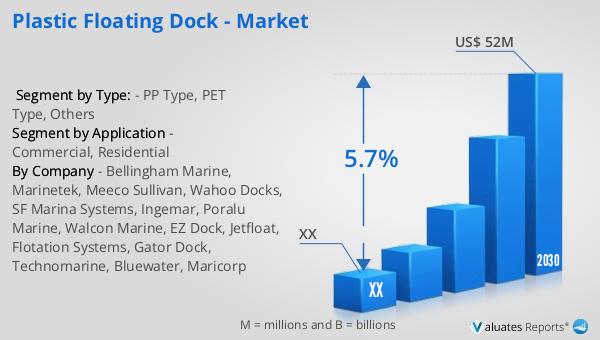

Plastic Floating Dock - Global Market Outlook:

The global market for plastic floating docks was valued at approximately $35 million in 2023. Looking ahead, this market is projected to expand, reaching an estimated value of $52 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 5.7% over the forecast period from 2024 to 2030. This anticipated growth can be attributed to several factors, including the increasing demand for durable and versatile docking solutions across various sectors. As more industries and individuals recognize the benefits of plastic floating docks, such as their resistance to corrosion, ease of installation, and environmental sustainability, the market is expected to experience steady expansion. Additionally, advancements in material technology and design are likely to enhance the functionality and appeal of these docks, further driving their adoption in both commercial and residential applications. The projected growth of the plastic floating dock market underscores the importance of these structures in modern waterfront development and their potential to contribute to sustainable and efficient water-based infrastructure. As the market continues to evolve, stakeholders can expect to see new innovations and opportunities emerge, supporting the ongoing expansion of this dynamic industry.

| Report Metric | Details |

| Report Name | Plastic Floating Dock - Market |

| Forecasted market size in 2030 | US$ 52 million |

| CAGR | 5.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Bellingham Marine, Marinetek, Meeco Sullivan, Wahoo Docks, SF Marina Systems, Ingemar, Poralu Marine, Walcon Marine, EZ Dock, Jetfloat, Flotation Systems, Gator Dock, Technomarine, Bluewater, Maricorp |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |