What is Passenger Wagons Rail Wheel - Global Market?

Passenger wagons rail wheels are a crucial component of the railway industry, serving as the foundation for the movement of passenger trains across the globe. These wheels are specifically designed to support the weight of passenger wagons and ensure smooth and safe travel on rail tracks. The global market for passenger wagons rail wheels is driven by the increasing demand for efficient and reliable rail transportation systems. As urbanization and population growth continue to rise, there is a growing need for public transportation solutions that can accommodate large numbers of passengers. Railways offer a sustainable and cost-effective mode of transport, making them an attractive option for governments and private operators alike. The market encompasses various types of rail wheels, including forged and cast wheels, each with its own set of advantages and applications. Manufacturers in this market are focused on developing advanced materials and technologies to enhance the performance and durability of rail wheels, thereby meeting the evolving needs of the railway industry. The global passenger wagons rail wheel market is characterized by a mix of established players and emerging companies, all striving to capture a share of this dynamic and competitive market.

Forged Wheels, Casting Wheels in the Passenger Wagons Rail Wheel - Global Market:

Forged wheels and cast wheels are two primary types of rail wheels used in passenger wagons, each offering distinct benefits and applications in the global market. Forged wheels are manufactured through a process that involves shaping metal using compressive forces, resulting in a dense and robust wheel structure. This method enhances the mechanical properties of the wheel, making it highly durable and resistant to wear and tear. Forged wheels are particularly favored in high-speed rail applications due to their ability to withstand significant stress and maintain stability at elevated speeds. Additionally, the forging process allows for precise control over the wheel's dimensions and properties, ensuring optimal performance and safety. On the other hand, cast wheels are produced by pouring molten metal into molds, allowing for more complex shapes and designs. This method is generally more cost-effective than forging, making cast wheels a popular choice for standard passenger rail applications where extreme performance characteristics are not as critical. Cast wheels offer good performance and reliability for everyday rail operations, providing a balance between cost and functionality. In the global market, the choice between forged and cast wheels often depends on factors such as budget constraints, specific performance requirements, and the intended application of the rail wheels. Manufacturers are continually innovating in both forging and casting technologies to improve the quality and efficiency of rail wheels. For instance, advancements in metallurgy and heat treatment processes have led to the development of wheels with enhanced strength and resistance to fatigue. Moreover, the integration of computer-aided design (CAD) and simulation tools in the manufacturing process has enabled producers to optimize wheel designs for better performance and longevity. Environmental considerations also play a role in the development of rail wheels, with manufacturers exploring eco-friendly materials and production methods to reduce the carbon footprint of their products. As the global market for passenger wagons rail wheels continues to evolve, the demand for both forged and cast wheels is expected to grow, driven by the expansion of rail networks and the modernization of existing infrastructure. Companies operating in this market are investing in research and development to stay competitive and meet the diverse needs of their customers. The interplay between cost, performance, and sustainability will likely shape the future landscape of the passenger wagons rail wheel market, influencing the adoption of forged and cast wheels across different regions and applications.

OE Market, After Market in the Passenger Wagons Rail Wheel - Global Market:

The usage of passenger wagons rail wheels in the global market can be broadly categorized into two segments: the Original Equipment (OE) market and the aftermarket. The OE market involves the supply of rail wheels to manufacturers of new passenger wagons, where these wheels are installed as part of the original assembly. This segment is driven by the demand for new rail vehicles, which is influenced by factors such as infrastructure development, urbanization, and government investments in public transportation. In the OE market, manufacturers focus on delivering high-quality, reliable wheels that meet the stringent safety and performance standards required for new rail vehicles. The choice of materials and manufacturing processes is critical in this segment, as rail operators seek wheels that offer long service life and minimal maintenance requirements. On the other hand, the aftermarket involves the supply of rail wheels for replacement and maintenance purposes. This segment is crucial for ensuring the continued safe and efficient operation of existing passenger wagons. As rail vehicles age, their wheels are subject to wear and tear, necessitating regular inspection and replacement to maintain optimal performance. The aftermarket provides opportunities for manufacturers to offer a range of products, including standard replacement wheels and specialized solutions tailored to specific rail systems. In this segment, factors such as cost-effectiveness, availability, and compatibility with existing rail vehicles are key considerations for rail operators. The aftermarket also presents opportunities for innovation, as manufacturers develop advanced wheel designs and materials to enhance the performance and longevity of replacement wheels. Both the OE market and the aftermarket are integral to the global passenger wagons rail wheel market, with each segment offering unique challenges and opportunities. Manufacturers must navigate the complexities of these markets, balancing the need for high-quality products with competitive pricing and efficient supply chains. As the global rail industry continues to grow and evolve, the demand for passenger wagons rail wheels in both the OE market and the aftermarket is expected to increase, driven by the expansion of rail networks and the modernization of existing infrastructure. Companies operating in this market are investing in research and development to stay competitive and meet the diverse needs of their customers. The interplay between cost, performance, and sustainability will likely shape the future landscape of the passenger wagons rail wheel market, influencing the adoption of forged and cast wheels across different regions and applications.

Passenger Wagons Rail Wheel - Global Market Outlook:

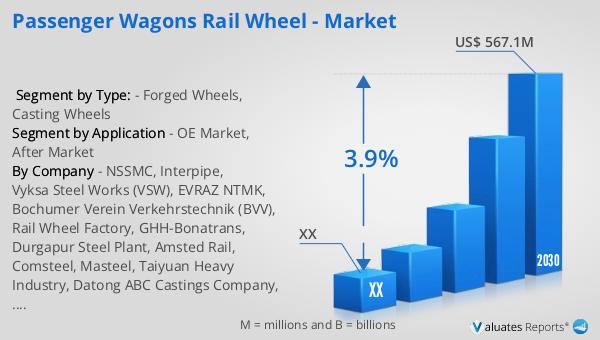

In 2023, the global market for passenger wagons rail wheels was valued at approximately $435.5 million. Looking ahead, this market is projected to experience growth, reaching an estimated value of $567.1 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 3.9% during the forecast period from 2024 to 2030. This upward trend in market size reflects the increasing demand for rail transportation solutions worldwide, driven by factors such as urbanization, population growth, and the need for sustainable and efficient public transport systems. As governments and private operators invest in expanding and modernizing rail infrastructure, the demand for high-quality rail wheels is expected to rise. This growth also underscores the importance of innovation and technological advancements in the rail wheel industry, as manufacturers strive to develop products that meet the evolving needs of the market. The projected increase in market size highlights the opportunities for companies operating in this sector to capitalize on the growing demand for passenger wagons rail wheels, both in terms of original equipment and aftermarket solutions. As the market continues to expand, companies will need to focus on delivering reliable, cost-effective, and sustainable products to maintain a competitive edge.

| Report Metric | Details |

| Report Name | Passenger Wagons Rail Wheel - Market |

| Forecasted market size in 2030 | US$ 567.1 million |

| CAGR | 3.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | NSSMC, Interpipe, Vyksa Steel Works (VSW), EVRAZ NTMK, Bochumer Verein Verkehrstechnik (BVV), Rail Wheel Factory, GHH-Bonatrans, Durgapur Steel Plant, Amsted Rail, Comsteel, Masteel, Taiyuan Heavy Industry, Datong ABC Castings Company, Xinyang Tonghe wheels |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |