What is Pan Conveyor - Global Market?

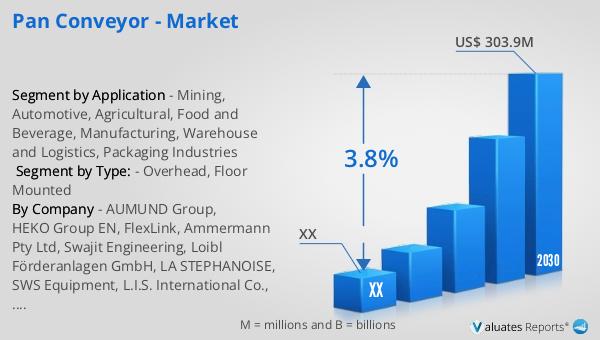

Pan conveyors are an essential component in the global market, designed to handle the transportation of bulk materials and heavy loads across various industries. These conveyors are characterized by their robust construction and ability to operate in challenging environments, making them indispensable in sectors that demand durability and efficiency. The global market for pan conveyors is driven by the need for efficient material handling solutions that can withstand the rigors of heavy-duty applications. Industries such as mining, automotive, agriculture, and manufacturing rely heavily on these conveyors to streamline operations and enhance productivity. The versatility of pan conveyors allows them to be customized to meet specific industry requirements, further boosting their demand. As industries continue to evolve and expand, the need for reliable and efficient material handling solutions like pan conveyors is expected to grow, contributing to the market's steady expansion. The global market for pan conveyors was valued at approximately US$ 237 million in 2023, with projections indicating a growth to US$ 303.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.8% during the forecast period from 2024 to 2030. This growth underscores the increasing importance of pan conveyors in supporting industrial operations worldwide.

Overhead, Floor Mounted in the Pan Conveyor - Global Market:

In the realm of pan conveyors, two primary configurations are prevalent: overhead and floor-mounted systems. Each configuration offers unique advantages and is suited to specific applications, contributing to the versatility and adaptability of pan conveyors in the global market. Overhead pan conveyors are typically suspended from the ceiling or an elevated structure, allowing for the efficient transportation of materials above ground level. This configuration is particularly advantageous in environments where floor space is limited or where it is essential to keep the ground clear for other operations. Overhead conveyors are commonly used in industries such as automotive manufacturing, where they facilitate the movement of parts and components along the production line without interfering with ground-level activities. The elevated design also helps in reducing the risk of damage to materials and equipment, as they are less likely to be impacted by ground-level hazards. On the other hand, floor-mounted pan conveyors are installed directly on the ground, providing a stable and robust solution for transporting heavy loads and bulk materials. This configuration is ideal for industries such as mining and agriculture, where the transportation of large quantities of raw materials is required. Floor-mounted conveyors are designed to withstand the harsh conditions often encountered in these industries, including exposure to dust, moisture, and extreme temperatures. Their sturdy construction ensures reliable performance even in the most demanding environments, making them a preferred choice for heavy-duty applications. The choice between overhead and floor-mounted pan conveyors depends largely on the specific needs of the industry and the nature of the materials being transported. Both configurations offer significant benefits in terms of efficiency, reliability, and adaptability, making them integral components of modern material handling systems. As industries continue to seek innovative solutions to enhance productivity and streamline operations, the demand for both overhead and floor-mounted pan conveyors is expected to remain strong, driving growth in the global market.

Mining, Automotive, Agricultural, Food and Beverage, Manufacturing, Warehouse and Logistics, Packaging Industries in the Pan Conveyor - Global Market:

Pan conveyors play a crucial role in various industries, providing efficient and reliable solutions for the transportation of materials. In the mining industry, pan conveyors are used to transport bulk materials such as coal, ore, and other minerals from extraction sites to processing facilities. Their robust construction and ability to handle heavy loads make them ideal for the demanding conditions of mining operations. In the automotive industry, pan conveyors are employed to move parts and components along the production line, ensuring a smooth and efficient manufacturing process. Their versatility allows them to be integrated into complex assembly lines, facilitating the seamless flow of materials and reducing production downtime. In agriculture, pan conveyors are used to transport grains, seeds, and other agricultural products, helping to streamline operations and improve efficiency. Their ability to handle large volumes of materials makes them an essential tool for modern agricultural practices. In the food and beverage industry, pan conveyors are used to transport raw materials and finished products, ensuring that they are moved quickly and efficiently through the production process. Their hygienic design and ease of cleaning make them suitable for handling food products, maintaining high standards of safety and quality. In manufacturing, pan conveyors are used to transport raw materials, components, and finished products, helping to optimize production processes and improve overall efficiency. Their adaptability allows them to be customized to meet the specific needs of different manufacturing environments. In warehouse and logistics operations, pan conveyors are used to move goods and materials, facilitating the efficient handling and distribution of products. Their ability to handle a wide range of materials makes them an invaluable asset in modern logistics operations. In the packaging industry, pan conveyors are used to transport packaging materials and finished products, ensuring that they are moved quickly and efficiently through the production process. Their versatility and reliability make them an essential component of modern packaging operations, helping to improve efficiency and reduce production costs.

Pan Conveyor - Global Market Outlook:

The global market for pan conveyors was valued at approximately US$ 237 million in 2023, with projections indicating a growth to US$ 303.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.8% during the forecast period from 2024 to 2030. This growth underscores the increasing importance of pan conveyors in supporting industrial operations worldwide. Pan conveyors are specifically designed for heavy-duty applications, making them suitable for industries that require the transportation of bulk materials or heavy loads. Their robust construction and ability to operate in challenging environments make them indispensable in sectors that demand durability and efficiency. The versatility of pan conveyors allows them to be customized to meet specific industry requirements, further boosting their demand. As industries continue to evolve and expand, the need for reliable and efficient material handling solutions like pan conveyors is expected to grow, contributing to the market's steady expansion. The projected growth in the global market for pan conveyors reflects the increasing demand for efficient and reliable material handling solutions across various industries. As industries continue to evolve and expand, the need for reliable and efficient material handling solutions like pan conveyors is expected to grow, contributing to the market's steady expansion. This growth underscores the increasing importance of pan conveyors in supporting industrial operations worldwide.

| Report Metric | Details |

| Report Name | Pan Conveyor - Market |

| Forecasted market size in 2030 | US$ 303.9 million |

| CAGR | 3.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | AUMUND Group, HEKO Group EN, FlexLink, Ammermann Pty Ltd, Swajit Engineering, Loibl Förderanlagen GmbH, LA STEPHANOISE, SWS Equipment, L.I.S. International Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |