What is Inventory Tank Gauging System - Global Market?

Inventory Tank Gauging Systems are essential tools used globally to measure and monitor the levels of liquids within storage tanks. These systems are crucial for industries that rely on accurate inventory management, such as oil and gas, chemicals, and water treatment. The primary function of these systems is to provide precise measurements of the liquid levels, which helps in maintaining optimal inventory levels, preventing overflows, and ensuring safety. The global market for Inventory Tank Gauging Systems is driven by the increasing demand for efficient and accurate inventory management solutions. With advancements in technology, these systems have evolved to offer real-time data, remote monitoring capabilities, and integration with other industrial systems. This evolution has made them indispensable in modern industrial operations. The market is characterized by a variety of products, including radar, ultrasonic, and servo-based gauging systems, each offering unique benefits and applications. As industries continue to prioritize efficiency and safety, the demand for advanced Inventory Tank Gauging Systems is expected to grow, making it a vital component of industrial infrastructure worldwide.

Point Level Instruments, Continuous Level Instruments in the Inventory Tank Gauging System - Global Market:

Point Level Instruments and Continuous Level Instruments are two primary categories of devices used in Inventory Tank Gauging Systems, each serving distinct purposes in the global market. Point Level Instruments are designed to detect the presence or absence of a liquid at a specific point within a tank. These instruments are typically used for high-level alarms, spill prevention, and pump control. They are crucial in applications where it is essential to know when a tank reaches a certain level to trigger an action, such as stopping a pump or opening a valve. Common types of point level instruments include float switches, capacitance probes, and vibrating forks. These devices are valued for their simplicity, reliability, and cost-effectiveness, making them a popular choice in various industries. On the other hand, Continuous Level Instruments provide ongoing measurement of liquid levels within a tank, offering a complete picture of the tank's contents at any given time. These instruments are essential for applications that require precise and continuous monitoring of liquid levels, such as in the oil and gas industry, where accurate inventory management is critical. Continuous level instruments include technologies such as radar, ultrasonic, and magnetostrictive sensors. Radar level instruments, for example, use microwave signals to measure the distance to the liquid surface, providing highly accurate and reliable measurements even in challenging conditions. Ultrasonic level instruments, meanwhile, use sound waves to determine the liquid level, offering a non-contact measurement solution that is ideal for corrosive or hazardous liquids. Magnetostrictive sensors provide high precision and are often used in applications requiring detailed level measurement and control. The global market for these instruments is driven by the need for accurate and reliable level measurement solutions across various industries. As industries continue to evolve and demand more sophisticated inventory management systems, the adoption of advanced point level and continuous level instruments is expected to increase. These instruments not only enhance operational efficiency but also contribute to safety and regulatory compliance by ensuring accurate monitoring and control of liquid levels. The integration of these instruments with digital technologies and IoT platforms further enhances their capabilities, allowing for real-time data analysis and remote monitoring. This integration is particularly beneficial in industries such as oil and gas, where timely and accurate data is crucial for decision-making and operational efficiency. In conclusion, both point level and continuous level instruments play a vital role in the global market for Inventory Tank Gauging Systems. Their ability to provide accurate and reliable level measurements makes them indispensable tools for industries that rely on precise inventory management. As technology continues to advance, these instruments are expected to become even more sophisticated, offering enhanced features and capabilities that will further drive their adoption in the global market.

Aviation, Defense, Oil & Gas, Others in the Inventory Tank Gauging System - Global Market:

Inventory Tank Gauging Systems are utilized across various sectors, including aviation, defense, oil and gas, and others, each with specific requirements and applications. In the aviation industry, these systems are crucial for managing fuel inventory in storage tanks at airports and refueling stations. Accurate measurement of fuel levels ensures efficient fuel management, reduces the risk of overfilling, and helps in maintaining safety standards. The ability to monitor fuel levels in real-time allows for better planning and coordination of refueling operations, minimizing downtime and ensuring the availability of fuel when needed. In the defense sector, Inventory Tank Gauging Systems are used to manage fuel and other liquid inventories at military bases and installations. These systems provide the accuracy and reliability needed to ensure that critical operations are not disrupted due to fuel shortages or overflows. The ability to integrate these systems with other logistics and supply chain management tools enhances their utility, allowing for efficient management of resources and improved operational readiness. The oil and gas industry is one of the largest users of Inventory Tank Gauging Systems, where they are used to monitor the levels of crude oil, refined products, and other liquids in storage tanks. Accurate measurement of these levels is critical for inventory management, regulatory compliance, and safety. These systems help prevent overfills, leaks, and spills, which can have significant environmental and financial consequences. The integration of these systems with digital platforms and IoT technologies allows for real-time monitoring and data analysis, enabling better decision-making and operational efficiency. Beyond these sectors, Inventory Tank Gauging Systems are also used in industries such as chemicals, water treatment, and food and beverage. In the chemical industry, these systems help manage the levels of various chemicals in storage tanks, ensuring safety and compliance with regulatory standards. In water treatment facilities, they are used to monitor the levels of water and other liquids, helping to optimize treatment processes and ensure the availability of clean water. In the food and beverage industry, these systems are used to manage the levels of ingredients and finished products, ensuring quality and consistency. Overall, the use of Inventory Tank Gauging Systems across these sectors highlights their importance in modern industrial operations. Their ability to provide accurate and reliable measurements, coupled with their integration with digital technologies, makes them indispensable tools for efficient inventory management and operational efficiency. As industries continue to evolve and face new challenges, the demand for advanced Inventory Tank Gauging Systems is expected to grow, further cementing their role in global industrial infrastructure.

Inventory Tank Gauging System - Global Market Outlook:

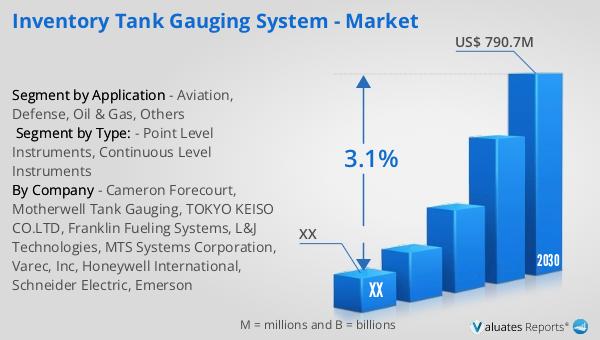

The global market for Inventory Tank Gauging Systems was valued at approximately $637.8 million in 2023. It is projected to grow to a revised size of $790.7 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.1% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for accurate and efficient inventory management solutions across various industries. In North America, the market for Inventory Tank Gauging Systems was valued at a certain amount in 2023 and is expected to reach a different value by 2030, with a specific CAGR during the forecast period from 2024 through 2030. This regional growth underscores the importance of these systems in managing liquid inventories, ensuring safety, and enhancing operational efficiency. The market dynamics are influenced by factors such as technological advancements, regulatory requirements, and the need for real-time data and remote monitoring capabilities. As industries continue to prioritize efficiency and safety, the adoption of advanced Inventory Tank Gauging Systems is expected to increase, driving market growth and innovation. The integration of these systems with digital platforms and IoT technologies further enhances their capabilities, making them a vital component of modern industrial operations.

| Report Metric | Details |

| Report Name | Inventory Tank Gauging System - Market |

| Forecasted market size in 2030 | US$ 790.7 million |

| CAGR | 3.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Cameron Forecourt, Motherwell Tank Gauging, TOKYO KEISO CO.LTD, Franklin Fueling Systems, L&J Technologies, MTS Systems Corporation, Varec, Inc, Honeywell International, Schneider Electric, Emerson |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |