What is Inventory Tag System - Global Market?

The Inventory Tag System is a crucial component in the global market, serving as a fundamental tool for tracking and managing inventory across various industries. This system involves the use of tags, which can be made from different materials such as paper, plastic, or metal, to label and monitor items within a warehouse or retail environment. These tags often contain barcodes or RFID technology, allowing for efficient scanning and data collection. The primary purpose of an inventory tag system is to streamline the inventory management process, reduce errors, and enhance accuracy in stock levels. By implementing such a system, businesses can maintain optimal inventory levels, minimize losses due to overstocking or stockouts, and improve overall operational efficiency. The global market for inventory tag systems is expanding as more companies recognize the benefits of adopting advanced inventory management solutions. This growth is driven by the increasing demand for real-time inventory tracking, the need for improved supply chain visibility, and the rising adoption of automation technologies in various sectors. As businesses continue to seek ways to optimize their operations and reduce costs, the inventory tag system market is expected to witness significant advancements and innovations.

Paper, Plastic, Metal in the Inventory Tag System - Global Market:

In the global market for inventory tag systems, materials such as paper, plastic, and metal play a significant role in determining the functionality and durability of the tags used. Paper-based inventory tags are often favored for their cost-effectiveness and ease of use. They are typically used in environments where the tags do not need to withstand harsh conditions, making them ideal for indoor settings or short-term use. Paper tags can be easily printed with barcodes or other identifying information, allowing for quick and efficient labeling of products. However, they may not be suitable for environments with high moisture or where the tags are subject to wear and tear. On the other hand, plastic-based inventory tags offer greater durability and resistance to environmental factors such as moisture, chemicals, and abrasion. These tags are often used in industries where the inventory is exposed to challenging conditions, such as manufacturing or outdoor storage. Plastic tags can be designed with various features, including RFID technology, to enhance their functionality and provide real-time tracking capabilities. They are also available in different colors and sizes, allowing for easy categorization and identification of inventory items. Metal-based inventory tags are the most robust option, offering exceptional durability and resistance to extreme conditions. These tags are commonly used in industries such as logistics, where inventory is frequently handled and transported. Metal tags can withstand high temperatures, corrosion, and physical impact, making them ideal for long-term use in demanding environments. They are often equipped with advanced tracking technologies, such as RFID or QR codes, to facilitate efficient inventory management. Despite their higher cost, metal tags are valued for their longevity and reliability, providing a cost-effective solution for businesses that require durable inventory tracking solutions. The choice of material for inventory tags depends on various factors, including the specific requirements of the industry, the environmental conditions in which the tags will be used, and the desired level of functionality. As the global market for inventory tag systems continues to grow, manufacturers are investing in research and development to create innovative materials and designs that meet the evolving needs of businesses. This includes the development of eco-friendly materials and sustainable manufacturing processes to address the increasing demand for environmentally conscious solutions. By offering a range of materials with different properties and capabilities, the inventory tag system market is able to cater to a diverse array of industries and applications, ensuring that businesses can find the right solution to meet their inventory management needs.

Industrial, Retail, Logistics, Others in the Inventory Tag System - Global Market:

The usage of inventory tag systems in the global market spans across various sectors, including industrial, retail, logistics, and others, each benefiting from the enhanced inventory management capabilities these systems provide. In the industrial sector, inventory tag systems are crucial for managing large volumes of raw materials, components, and finished products. By implementing these systems, manufacturers can track the movement of inventory throughout the production process, ensuring that materials are available when needed and reducing the risk of production delays. The ability to monitor inventory levels in real-time allows for better planning and forecasting, ultimately leading to increased efficiency and cost savings. In the retail sector, inventory tag systems play a vital role in maintaining accurate stock levels and preventing stockouts or overstock situations. Retailers can use these systems to track the movement of products from the warehouse to the sales floor, ensuring that popular items are always available for customers. By providing real-time data on inventory levels, these systems enable retailers to make informed decisions about restocking and promotions, improving customer satisfaction and sales performance. In the logistics sector, inventory tag systems are essential for managing the movement of goods throughout the supply chain. These systems provide visibility into the location and status of inventory at every stage of the logistics process, from warehousing to transportation and delivery. By using inventory tags equipped with RFID or GPS technology, logistics companies can track shipments in real-time, reducing the risk of lost or misplaced items and improving overall supply chain efficiency. Other sectors, such as healthcare, food and beverage, and automotive, also benefit from the use of inventory tag systems. In healthcare, these systems are used to track medical supplies and equipment, ensuring that critical items are always available when needed. In the food and beverage industry, inventory tag systems help manage perishable goods, reducing waste and ensuring compliance with safety regulations. In the automotive sector, these systems are used to track parts and components, streamlining the manufacturing process and reducing the risk of production delays. Overall, the adoption of inventory tag systems across various industries highlights the importance of efficient inventory management in today's competitive market. By providing real-time visibility and control over inventory, these systems enable businesses to optimize their operations, reduce costs, and improve customer satisfaction. As the global market for inventory tag systems continues to grow, businesses in all sectors are recognizing the value of investing in advanced inventory management solutions to stay ahead of the competition.

Inventory Tag System - Global Market Outlook:

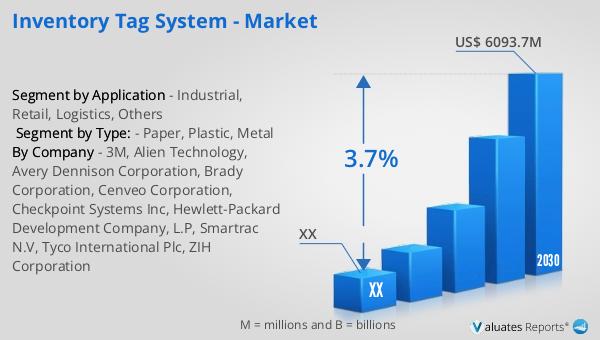

The global market for inventory tag systems was valued at approximately $4,710.5 million in 2023, with projections indicating a growth to around $6,093.7 million by 2030. This growth represents a compound annual growth rate (CAGR) of 3.7% during the forecast period from 2024 to 2030. This steady growth is indicative of the increasing demand for efficient inventory management solutions across various industries. The North American market, in particular, is expected to see significant growth, although specific figures for this region were not provided. The adoption of inventory tag systems in North America is driven by the need for improved supply chain visibility and the integration of advanced technologies such as RFID and IoT in inventory management processes. As businesses in this region continue to seek ways to enhance operational efficiency and reduce costs, the demand for inventory tag systems is expected to rise. The global market's expansion is also fueled by the growing awareness of the benefits of real-time inventory tracking and the need for accurate stock management in today's fast-paced business environment. As companies strive to remain competitive, the adoption of inventory tag systems is becoming increasingly essential, driving the market's growth and innovation.

| Report Metric | Details |

| Report Name | Inventory Tag System - Market |

| Forecasted market size in 2030 | US$ 6093.7 million |

| CAGR | 3.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | 3M, Alien Technology, Avery Dennison Corporation, Brady Corporation, Cenveo Corporation, Checkpoint Systems Inc, Hewlett-Packard Development Company, L.P, Smartrac N.V, Tyco International Plc, ZIH Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |