What is Global Prismatic Battery Structure Components Market?

The Global Prismatic Battery Structure Components Market refers to the industry focused on the production and distribution of components used in prismatic batteries. Prismatic batteries are a type of lithium-ion battery characterized by their rectangular shape, which allows for better space utilization in various applications. These batteries are widely used in electric vehicles, electronic equipment, and energy storage systems due to their high energy density and efficient design. The market for prismatic battery structure components includes materials such as steel shells, aluminum shells, and plastic cases, which are essential for the construction and protection of these batteries. As the demand for electric vehicles and renewable energy solutions continues to grow, the market for prismatic battery structure components is expected to expand significantly. This growth is driven by the need for more efficient and reliable energy storage solutions that can support the increasing adoption of clean energy technologies.

Steel Shell, Aluminum Shell, Plastic Case in the Global Prismatic Battery Structure Components Market:

Steel shells, aluminum shells, and plastic cases are critical components in the Global Prismatic Battery Structure Components Market. Steel shells are known for their durability and strength, making them ideal for applications that require robust protection against physical damage. They are commonly used in electric vehicles and industrial energy storage systems where safety and longevity are paramount. The steel shell provides a sturdy enclosure that can withstand high levels of stress and impact, ensuring the battery's integrity over time. On the other hand, aluminum shells offer a lightweight alternative to steel. Aluminum is known for its excellent thermal conductivity and corrosion resistance, making it suitable for applications where weight reduction and heat dissipation are crucial. Aluminum shells are often used in portable electronic devices and electric vehicles to enhance performance and efficiency. The lightweight nature of aluminum helps in reducing the overall weight of the battery pack, which is particularly beneficial for electric vehicles aiming to improve their range and energy efficiency. Plastic cases, meanwhile, provide a cost-effective and versatile option for prismatic battery enclosures. They are typically used in consumer electronics and smaller energy storage systems where weight and cost are significant considerations. Plastic cases can be molded into various shapes and sizes, offering flexibility in design and manufacturing. They also provide adequate protection against environmental factors such as moisture and dust, ensuring the battery's longevity and reliability. Each of these materials—steel, aluminum, and plastic—plays a unique role in the prismatic battery structure components market, catering to different needs and applications. The choice of material depends on factors such as the specific requirements of the application, cost considerations, and performance criteria. As the demand for prismatic batteries continues to rise, manufacturers are constantly exploring new materials and technologies to enhance the performance and efficiency of these components. This ongoing innovation is crucial for meeting the evolving needs of various industries and supporting the global transition towards cleaner and more sustainable energy solutions.

Electric Car, Electronic Equipment, Energy Storage System, Others in the Global Prismatic Battery Structure Components Market:

The usage of Global Prismatic Battery Structure Components Market spans across various sectors, including electric cars, electronic equipment, energy storage systems, and others. In electric cars, prismatic batteries are favored for their high energy density and efficient space utilization. The rectangular shape of prismatic batteries allows for better integration into the vehicle's design, maximizing the available space and improving the overall energy storage capacity. This is particularly important for electric vehicles, where optimizing battery performance and range is crucial. The robust construction of prismatic battery components, such as steel and aluminum shells, ensures the safety and durability of the battery pack, which is essential for the demanding conditions of automotive applications. In electronic equipment, prismatic batteries are used in devices such as laptops, smartphones, and tablets. The compact and lightweight design of prismatic batteries makes them ideal for portable electronic devices, where space and weight are critical factors. Aluminum shells are commonly used in these applications to enhance thermal management and reduce the overall weight of the device. The versatility of plastic cases also allows for customized designs that fit the specific requirements of different electronic products. Energy storage systems, both residential and commercial, also benefit from the use of prismatic batteries. These systems require reliable and efficient energy storage solutions to manage the intermittent nature of renewable energy sources such as solar and wind. Prismatic batteries, with their high energy density and robust construction, provide a dependable solution for storing and managing energy. Steel shells are often used in large-scale energy storage systems to ensure the safety and longevity of the battery packs. Additionally, prismatic batteries are used in various other applications, including medical devices, aerospace, and telecommunications. The adaptability of prismatic battery components to different requirements and environments makes them a versatile choice for a wide range of industries. As the demand for efficient and reliable energy storage solutions continues to grow, the usage of prismatic battery structure components is expected to expand further, supporting the global shift towards sustainable energy technologies.

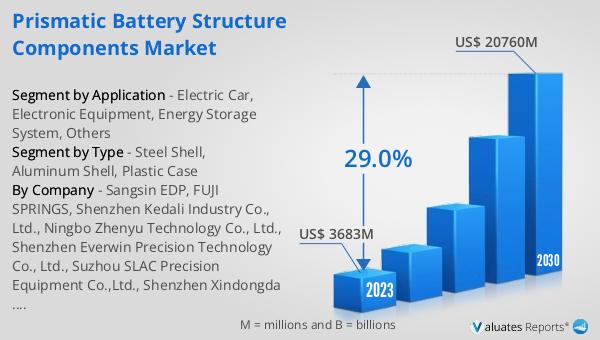

Global Prismatic Battery Structure Components Market Outlook:

The global Prismatic Battery Structure Components market was valued at US$ 3683 million in 2023 and is anticipated to reach US$ 20760 million by 2030, witnessing a CAGR of 29.0% during the forecast period 2024-2030. This significant growth reflects the increasing demand for prismatic battery components driven by the rising adoption of electric vehicles, renewable energy solutions, and advanced electronic devices. The market's expansion is fueled by the need for efficient and reliable energy storage solutions that can support the global transition towards cleaner and more sustainable energy technologies. As industries continue to innovate and develop new applications for prismatic batteries, the demand for high-quality structure components such as steel shells, aluminum shells, and plastic cases is expected to rise. These components play a crucial role in ensuring the performance, safety, and longevity of prismatic batteries, making them essential for various applications. The projected growth of the market highlights the importance of ongoing research and development efforts to enhance the materials and technologies used in prismatic battery components. By improving the efficiency and reliability of these components, manufacturers can better meet the evolving needs of different industries and contribute to the global efforts towards sustainable energy solutions.

| Report Metric | Details |

| Report Name | Prismatic Battery Structure Components Market |

| Accounted market size in 2023 | US$ 3683 million |

| Forecasted market size in 2030 | US$ 20760 million |

| CAGR | 29.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sangsin EDP, FUJI SPRINGS, Shenzhen Kedali Industry Co., Ltd., Ningbo Zhenyu Technology Co., Ltd., Shenzhen Everwin Precision Technology Co., Ltd., Suzhou SLAC Precision Equipment Co.,Ltd., Shenzhen Xindongda Technology Co., Ltd., Dongguan ALI System CO.,Ltd., Wuxi JinYang New Materials Co.,Ltd., Changzhou Ruidefeng Precision Manufacturing Co.,Ltd., Shenzhen Selen Science and Technology Co.,Ltd., Lingyi Itech(guangdong)company |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |