What is Global Magnesium Alloy Injection Molding Market?

The Global Magnesium Alloy Injection Molding Market is a specialized segment within the broader materials and manufacturing industry. This market focuses on the production and application of magnesium alloys through the process of injection molding. Magnesium alloys are lightweight, strong, and possess excellent thermal conductivity, making them ideal for various industrial applications. Injection molding is a manufacturing process that involves injecting molten material into a mold to create complex shapes with high precision. The combination of magnesium alloys and injection molding technology offers significant advantages, such as reduced weight, enhanced strength, and improved thermal management. These benefits make magnesium alloy injection molding a preferred choice in industries like automotive, consumer electronics, aerospace, and defense. The market is driven by the increasing demand for lightweight and durable materials that can enhance the performance and efficiency of end products. As industries continue to seek innovative solutions to meet evolving consumer needs and regulatory requirements, the Global Magnesium Alloy Injection Molding Market is expected to grow steadily.

AM, AS, AZ in the Global Magnesium Alloy Injection Molding Market:

In the context of the Global Magnesium Alloy Injection Molding Market, AM, AS, and AZ are specific types of magnesium alloys that are widely used due to their unique properties. AM alloys, which typically contain aluminum and manganese, are known for their excellent corrosion resistance and good mechanical properties. These alloys are often used in applications where durability and resistance to environmental factors are critical. AS alloys, on the other hand, include aluminum and silicon as their primary alloying elements. These alloys are characterized by their high strength and good castability, making them suitable for complex shapes and structures. AS alloys are commonly used in the automotive and aerospace industries, where high performance and reliability are essential. AZ alloys, which contain aluminum and zinc, are renowned for their exceptional strength-to-weight ratio and good ductility. These properties make AZ alloys ideal for applications that require lightweight yet strong materials, such as in consumer electronics and transportation. The choice of alloy depends on the specific requirements of the application, including factors like mechanical strength, corrosion resistance, and thermal conductivity. By leveraging the unique properties of AM, AS, and AZ alloys, manufacturers can optimize the performance and efficiency of their products, thereby meeting the diverse needs of various industries.

Automotive and Transportation, Consumer Electronics, Aerospace and Defense, Others in the Global Magnesium Alloy Injection Molding Market:

The Global Magnesium Alloy Injection Molding Market finds extensive usage in several key areas, including automotive and transportation, consumer electronics, aerospace and defense, and others. In the automotive and transportation sector, magnesium alloy injection molding is used to produce lightweight components that enhance fuel efficiency and reduce emissions. Parts such as engine blocks, transmission cases, and structural components benefit from the high strength-to-weight ratio of magnesium alloys, leading to improved vehicle performance and safety. In consumer electronics, magnesium alloy injection molding is employed to create durable and lightweight casings for devices like smartphones, laptops, and cameras. The excellent thermal conductivity of magnesium alloys also helps in effective heat dissipation, ensuring the longevity and reliability of electronic components. In the aerospace and defense industry, magnesium alloy injection molding is used to manufacture critical components that require high strength, low weight, and resistance to extreme conditions. Applications include aircraft fuselages, missile casings, and other structural parts that benefit from the superior properties of magnesium alloys. Other areas where magnesium alloy injection molding is utilized include medical devices, sports equipment, and industrial machinery. The versatility and performance advantages of magnesium alloys make them a valuable material choice across a wide range of applications, driving the growth and adoption of injection molding technology in these sectors.

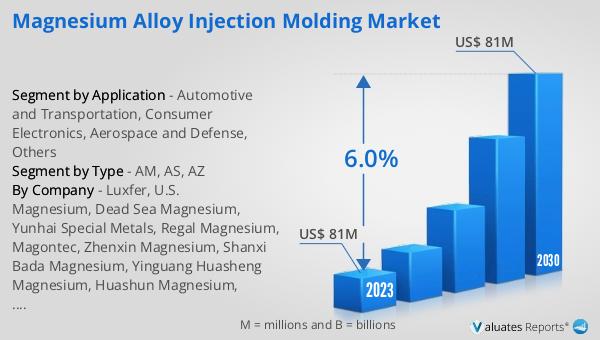

Global Magnesium Alloy Injection Molding Market Outlook:

The global Magnesium Alloy Injection Molding market was valued at US$ 81 million in 2023 and is anticipated to reach US$ 81 million by 2030, witnessing a CAGR of 6.0% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for lightweight and high-performance materials across various industries. The automotive and transportation sector, in particular, is expected to be a significant contributor to this growth, as manufacturers seek to enhance fuel efficiency and reduce emissions through the use of magnesium alloy components. Similarly, the consumer electronics industry is likely to benefit from the superior properties of magnesium alloys, such as durability and thermal conductivity, which are essential for the development of advanced electronic devices. The aerospace and defense sector is also poised to leverage the advantages of magnesium alloy injection molding to produce critical components that meet stringent performance and safety standards. Overall, the market outlook reflects a positive trend, with ongoing advancements in injection molding technology and increasing adoption of magnesium alloys across various applications.

| Report Metric | Details |

| Report Name | Magnesium Alloy Injection Molding Market |

| Accounted market size in 2023 | US$ 81 million |

| Forecasted market size in 2030 | US$ 81 million |

| CAGR | 6.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Luxfer, U.S. Magnesium, Dead Sea Magnesium, Yunhai Special Metals, Regal Magnesium, Magontec, Zhenxin Magnesium, Shanxi Bada Magnesium, Yinguang Huasheng Magnesium, Huashun Magnesium, Shaanxi Tianyu Magnesium |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |