What is Global Magnesium Alloy Ingot Market?

The Global Magnesium Alloy Ingot Market refers to the worldwide industry involved in the production, distribution, and utilization of magnesium alloy ingots. Magnesium alloy ingots are blocks of magnesium metal combined with other elements such as aluminum, zinc, and manganese to enhance their properties. These ingots are known for their lightweight, high strength-to-weight ratio, and excellent corrosion resistance, making them highly desirable in various industries. The market encompasses a wide range of activities, including mining and extraction of magnesium, alloying processes, manufacturing of ingots, and their application in different sectors. The demand for magnesium alloy ingots is driven by their use in automotive, aerospace, electronics, and other industries where lightweight and durable materials are essential. The market is influenced by factors such as technological advancements, environmental regulations, and economic conditions. Companies operating in this market focus on innovation and sustainability to meet the growing demand for high-performance materials. The global nature of this market means that it is subject to international trade dynamics and geopolitical factors, which can impact supply chains and pricing.

Cast Alloys, Wrought Alloys, Others in the Global Magnesium Alloy Ingot Market:

Magnesium alloy ingots are categorized into different types based on their composition and manufacturing processes, with the primary categories being cast alloys, wrought alloys, and others. Cast alloys are produced by melting and casting magnesium with other elements to form a solid ingot. These alloys are known for their excellent castability, making them suitable for complex shapes and large-scale production. They are widely used in the automotive industry for components such as engine blocks, transmission cases, and wheels due to their lightweight and high strength. Cast alloys also find applications in the aerospace sector for parts that require high performance and reliability. Wrought alloys, on the other hand, are processed through mechanical means such as rolling, extrusion, and forging. These alloys offer superior mechanical properties, including higher tensile strength and better ductility compared to cast alloys. Wrought magnesium alloys are commonly used in the manufacturing of structural components, such as aircraft fuselages, automotive body panels, and electronic housings. The "others" category includes specialty alloys and experimental compositions that are developed for specific applications or to meet unique performance requirements. These may include alloys with enhanced corrosion resistance, improved thermal conductivity, or tailored mechanical properties. The development and use of these specialized alloys are often driven by advancements in material science and engineering. The global magnesium alloy ingot market is characterized by continuous innovation and research to improve the properties and performance of these materials. Companies invest in R&D to develop new alloy compositions and manufacturing techniques that can meet the evolving demands of various industries. Environmental considerations also play a significant role in this market, as magnesium alloys are seen as a more sustainable alternative to heavier metals like steel and aluminum. The lightweight nature of magnesium alloys contributes to fuel efficiency and reduced emissions in automotive and aerospace applications, aligning with global efforts to combat climate change. The market is also influenced by economic factors, such as the availability and cost of raw materials, energy prices, and trade policies. Geopolitical factors can impact the supply chain, as magnesium production is concentrated in certain regions, leading to potential vulnerabilities in global supply. Overall, the global magnesium alloy ingot market is a dynamic and evolving industry that plays a crucial role in modern manufacturing and technology.

Automotive and Transportation, Consumer Electronics, Aerospace and Defense, Others in the Global Magnesium Alloy Ingot Market:

The usage of magnesium alloy ingots spans several key industries, including automotive and transportation, consumer electronics, aerospace and defense, and others. In the automotive and transportation sector, magnesium alloy ingots are highly valued for their lightweight properties, which contribute to improved fuel efficiency and reduced emissions. Components such as engine blocks, transmission cases, and wheels are commonly made from magnesium alloys due to their high strength-to-weight ratio. The use of magnesium alloys in automotive applications helps manufacturers meet stringent environmental regulations and enhance vehicle performance. In the consumer electronics industry, magnesium alloy ingots are used to produce lightweight and durable casings for devices such as laptops, smartphones, and cameras. The excellent thermal conductivity of magnesium alloys also makes them suitable for heat dissipation components in electronic devices, ensuring efficient cooling and prolonged device lifespan. The aerospace and defense sector relies on magnesium alloy ingots for the production of critical components that require high performance and reliability. Magnesium alloys are used in aircraft fuselages, engine components, and structural parts due to their lightweight and high strength. The use of magnesium alloys in aerospace applications helps reduce the overall weight of aircraft, leading to improved fuel efficiency and increased payload capacity. In the defense industry, magnesium alloys are used in the manufacturing of military vehicles, weapons, and protective gear, where their lightweight and durable properties are essential. Other industries that utilize magnesium alloy ingots include medical devices, sports equipment, and construction. In the medical field, magnesium alloys are used to produce lightweight and biocompatible implants and devices. In sports equipment, magnesium alloys are used to manufacture lightweight and high-performance gear such as bicycle frames, golf clubs, and tennis rackets. In the construction industry, magnesium alloys are used in the production of lightweight and durable building materials. The versatility and unique properties of magnesium alloy ingots make them a valuable material in various applications, driving their demand across multiple industries.

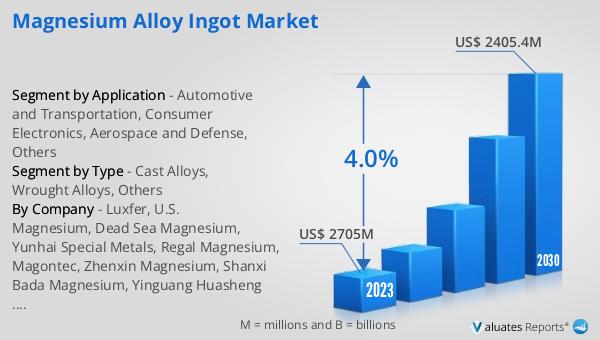

Global Magnesium Alloy Ingot Market Outlook:

The global Magnesium Alloy Ingot market was valued at US$ 2705 million in 2023 and is anticipated to reach US$ 2405.4 million by 2030, witnessing a CAGR of 4.0% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the magnesium alloy ingot industry over the next several years. The projected growth rate reflects the increasing demand for lightweight and high-performance materials in various industries, including automotive, aerospace, and electronics. The market's valuation in 2023 highlights the significant economic impact of magnesium alloy ingots, driven by their widespread use and unique properties. The anticipated market value by 2030 underscores the ongoing importance of these materials in modern manufacturing and technology. The compound annual growth rate (CAGR) of 4.0% suggests a consistent and sustainable increase in market demand, supported by advancements in material science, manufacturing processes, and environmental considerations. Companies operating in this market are likely to focus on innovation and sustainability to meet the evolving needs of their customers and maintain a competitive edge. The global nature of the magnesium alloy ingot market means that it is subject to international trade dynamics and geopolitical factors, which can impact supply chains and pricing. Overall, the market outlook for magnesium alloy ingots is positive, with steady growth expected over the forecast period.

| Report Metric | Details |

| Report Name | Magnesium Alloy Ingot Market |

| Accounted market size in 2023 | US$ 2705 million |

| Forecasted market size in 2030 | US$ 2405.4 million |

| CAGR | 4.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Luxfer, U.S. Magnesium, Dead Sea Magnesium, Yunhai Special Metals, Regal Magnesium, Magontec, Zhenxin Magnesium, Shanxi Bada Magnesium, Yinguang Huasheng Magnesium, Huashun Magnesium, Shaanxi Tianyu Magnesium |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |