What is Global Low Pressure Pouring Machine Market?

The Global Low Pressure Pouring Machine Market refers to the industry focused on the production and distribution of machines designed for the low-pressure pouring process, primarily used in metal casting. These machines are essential in industries where precision and quality of metal castings are crucial, such as automotive, aerospace, and machinery manufacturing. Low pressure pouring machines operate by filling molds with molten metal under controlled pressure, which minimizes turbulence and reduces the risk of defects in the final product. This method is particularly advantageous for producing complex shapes and high-quality castings with excellent mechanical properties. The market for these machines is driven by the growing demand for lightweight and durable metal components, advancements in casting technology, and the need for efficient production processes. As industries continue to seek ways to improve product quality and reduce manufacturing costs, the adoption of low pressure pouring machines is expected to increase, contributing to the market's growth. The market is characterized by a range of machine types and configurations, catering to different production needs and scales, from small workshops to large industrial operations.

Vertical, Horizontal in the Global Low Pressure Pouring Machine Market:

In the Global Low Pressure Pouring Machine Market, machines are typically categorized based on their orientation: vertical and horizontal. Vertical low pressure pouring machines are designed with a vertical mold orientation, which is particularly beneficial for casting components with complex geometries and intricate details. This orientation allows for better control over the flow of molten metal, reducing the likelihood of defects such as air entrapment and ensuring a more uniform distribution of material. Vertical machines are often preferred in applications where precision and surface finish are critical, such as in the aerospace and automotive industries. They are also advantageous in terms of space utilization, as they require a smaller footprint compared to horizontal machines. On the other hand, horizontal low pressure pouring machines feature a horizontal mold orientation, which is ideal for casting larger components or those with simpler geometries. The horizontal setup allows for easier handling and maintenance, making it suitable for high-volume production environments. These machines are commonly used in the manufacturing of large automotive parts, machinery components, and other industrial applications where speed and efficiency are prioritized. The choice between vertical and horizontal machines depends on various factors, including the specific requirements of the casting process, the size and complexity of the components being produced, and the available space and resources within the manufacturing facility. Both types of machines offer unique advantages and are integral to the diverse needs of the global low pressure pouring machine market. As technology continues to advance, manufacturers are developing innovative solutions to enhance the performance and versatility of both vertical and horizontal machines, further driving their adoption across different industries.

Automobile Industry, Textile Machinery, Aerospace Industry in the Global Low Pressure Pouring Machine Market:

The Global Low Pressure Pouring Machine Market finds significant applications in various industries, including the automobile industry, textile machinery, and aerospace industry. In the automobile industry, low pressure pouring machines are used to produce high-quality metal components such as engine blocks, cylinder heads, and transmission cases. These machines enable manufacturers to achieve precise dimensions and superior surface finishes, which are essential for the performance and reliability of automotive parts. The ability to produce lightweight yet durable components is particularly important in the automotive sector, where there is a constant push for fuel efficiency and reduced emissions. In the textile machinery industry, low pressure pouring machines are utilized to manufacture components that require high precision and durability, such as gears, frames, and housings. The machines' ability to produce complex shapes with minimal defects ensures the smooth operation and longevity of textile machinery, which is crucial for maintaining productivity and quality in textile manufacturing processes. In the aerospace industry, low pressure pouring machines play a vital role in the production of critical components such as turbine blades, structural parts, and landing gear. The aerospace sector demands the highest standards of quality and reliability, and low pressure pouring machines provide the precision and consistency needed to meet these stringent requirements. The machines' capability to produce complex geometries with excellent mechanical properties makes them indispensable in the aerospace industry, where safety and performance are paramount. Overall, the versatility and efficiency of low pressure pouring machines make them a valuable asset across various industries, contributing to improved product quality, reduced production costs, and enhanced competitiveness in the global market.

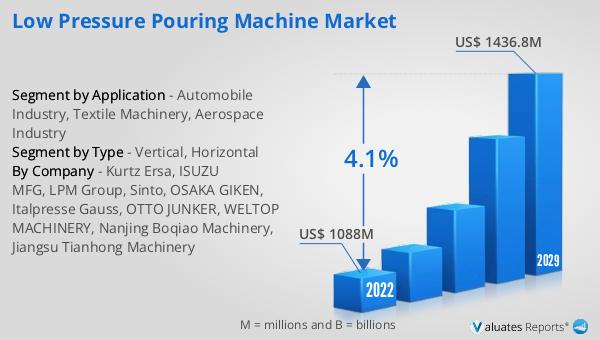

Global Low Pressure Pouring Machine Market Outlook:

In 2023, the global market for Low Pressure Pouring Machines was valued at approximately $1,088 million. This market is projected to grow steadily, reaching an estimated value of $1,436.8 million by the year 2030. This growth trajectory reflects a compound annual growth rate (CAGR) of 4.1% during the forecast period from 2024 to 2030. The anticipated growth in this market can be attributed to several factors, including the increasing demand for high-quality metal castings in various industries, advancements in casting technology, and the need for efficient and cost-effective production processes. As industries such as automotive, aerospace, and machinery manufacturing continue to evolve and expand, the demand for low pressure pouring machines is expected to rise, driving the market's growth. The market's expansion is also supported by the ongoing trend towards lightweight and durable metal components, which are essential for improving product performance and reducing environmental impact. As a result, manufacturers are increasingly investing in low pressure pouring machines to enhance their production capabilities and meet the growing demand for high-quality castings. This positive market outlook underscores the importance of low pressure pouring machines in modern manufacturing processes and highlights their potential for continued growth and innovation in the coming years.

| Report Metric | Details |

| Report Name | Low Pressure Pouring Machine Market |

| Accounted market size in 2023 | US$ 1088 million |

| Forecasted market size in 2030 | US$ 1436.8 million |

| CAGR | 4.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kurtz Ersa, ISUZU MFG, LPM Group, Sinto, OSAKA GIKEN, Italpresse Gauss, OTTO JUNKER, WELTOP MACHINERY, Nanjing Boqiao Machinery, Jiangsu Tianhong Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |