What is Global Industrial Water Tube Boilers Market?

The Global Industrial Water Tube Boilers Market refers to the worldwide industry focused on the production and sale of water tube boilers used in various industrial applications. These boilers are designed to generate steam or hot water by circulating water through tubes that are heated externally by combustion gases. The market encompasses a wide range of industries, including food processing, pulp and paper, chemical, refinery, and primary metal sectors, among others. Water tube boilers are favored for their ability to handle high-pressure steam and their efficiency in large-scale operations. The market is driven by the increasing demand for energy-efficient and environmentally friendly solutions, as well as the need for reliable and continuous steam supply in industrial processes. Technological advancements and innovations in boiler design and materials are also contributing to the growth of this market. As industries continue to expand and modernize, the demand for industrial water tube boilers is expected to rise, making this market a critical component of the global industrial landscape.

Condensing, Non-condensing in the Global Industrial Water Tube Boilers Market:

In the Global Industrial Water Tube Boilers Market, boilers are categorized into two main types: condensing and non-condensing. Condensing boilers are designed to maximize energy efficiency by capturing and utilizing the heat from exhaust gases that would otherwise be lost in non-condensing systems. This process involves cooling the exhaust gases to a point where water vapor condenses, releasing latent heat that is then used to preheat the incoming water. As a result, condensing boilers can achieve efficiency levels of up to 98%, making them an attractive option for industries looking to reduce energy consumption and lower operational costs. These boilers are particularly beneficial in applications where low-temperature return water is available, as this enhances the condensation process and improves overall efficiency. On the other hand, non-condensing boilers operate at lower efficiency levels, typically around 80-85%, as they do not recover the latent heat from exhaust gases. These boilers are often used in applications where high-temperature steam is required, and the return water temperature is too high to allow for effective condensation. Despite their lower efficiency, non-condensing boilers are still widely used due to their simpler design, lower initial cost, and ability to handle high-pressure steam applications. In the industrial sector, the choice between condensing and non-condensing boilers depends on various factors, including the specific requirements of the application, the availability of low-temperature return water, and the overall cost considerations. Industries that prioritize energy efficiency and environmental sustainability are increasingly opting for condensing boilers, while those with high-temperature steam needs or budget constraints may choose non-condensing options. The ongoing advancements in boiler technology are also influencing the market dynamics, with manufacturers focusing on developing more efficient and environmentally friendly solutions to meet the evolving needs of industrial users. As a result, the Global Industrial Water Tube Boilers Market is witnessing a shift towards more sustainable and energy-efficient solutions, driven by the growing awareness of environmental issues and the need for cost-effective energy management in industrial operations.

Food Processing, Pulp and Paper, Chemical, Refinery, Primary Metal, Others in the Global Industrial Water Tube Boilers Market:

The Global Industrial Water Tube Boilers Market plays a crucial role in various industries, including food processing, pulp and paper, chemical, refinery, primary metal, and others. In the food processing industry, water tube boilers are used to generate steam for cooking, sterilization, and other processes that require precise temperature control. The ability to produce high-pressure steam makes these boilers ideal for large-scale food production facilities, where efficiency and reliability are paramount. In the pulp and paper industry, water tube boilers are essential for generating the steam needed for the pulping process, drying paper, and other critical operations. The high-pressure steam produced by these boilers ensures that the production process runs smoothly and efficiently, minimizing downtime and maximizing output. In the chemical industry, water tube boilers are used to provide the steam required for various chemical reactions, distillation, and other processes. The ability to produce consistent and reliable steam is crucial for maintaining product quality and ensuring the safety of chemical operations. In refineries, water tube boilers are used to generate steam for heating crude oil, driving turbines, and other processes that require high-pressure steam. The efficiency and reliability of these boilers are critical for maintaining the continuous operation of refinery processes and minimizing energy consumption. In the primary metal industry, water tube boilers are used to generate steam for processes such as smelting, refining, and rolling. The high-pressure steam produced by these boilers is essential for maintaining the high temperatures required for metal production and ensuring the quality of the final product. Other industries that rely on water tube boilers include textiles, pharmaceuticals, and power generation, where the ability to produce high-pressure steam is essential for various processes. Overall, the Global Industrial Water Tube Boilers Market is a vital component of the industrial landscape, providing the steam and hot water needed for a wide range of applications across multiple industries.

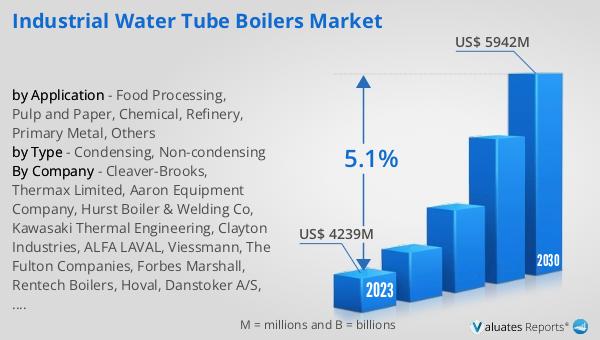

Global Industrial Water Tube Boilers Market Outlook:

The outlook for the Global Industrial Water Tube Boilers Market indicates a positive growth trajectory. In 2023, the market was valued at approximately US$ 4,239 million, and it is projected to reach around US$ 5,942 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.1% from 2024 to 2030. This upward trend reflects the increasing demand for efficient and reliable steam generation solutions across various industries. The market's expansion is driven by several factors, including the growing emphasis on energy efficiency, the need for sustainable industrial processes, and the continuous advancements in boiler technology. As industries strive to reduce their carbon footprint and operational costs, the adoption of advanced water tube boilers is becoming more prevalent. Additionally, the rising industrialization and modernization efforts in emerging economies are contributing to the market's growth, as these regions seek to enhance their industrial capabilities and infrastructure. The Global Industrial Water Tube Boilers Market is poised for significant growth in the coming years, driven by the increasing demand for efficient and sustainable steam generation solutions across various industries.

| Report Metric | Details |

| Report Name | Industrial Water Tube Boilers Market |

| Accounted market size in 2023 | US$ 4239 million |

| Forecasted market size in 2030 | US$ 5942 million |

| CAGR | 5.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Cleaver-Brooks, Thermax Limited, Aaron Equipment Company, Hurst Boiler & Welding Co, Kawasaki Thermal Engineering, Clayton Industries, ALFA LAVAL, Viessmann, The Fulton Companies, Forbes Marshall, Rentech Boilers, Hoval, Danstoker A/S, Spirax Sarco, Babcock Wanson, Miura Boiler, Hurst Boiler & Welding, SAACKE Group, Nationwide Boiler |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |