What is Global Full Automatic Laser Welding Machine for Lithium Battery Market?

The Global Full Automatic Laser Welding Machine for Lithium Battery Market is a specialized segment within the broader laser welding industry, focusing on the production and assembly of lithium batteries. These machines are designed to automate the welding process, ensuring precision, speed, and consistency, which are crucial for the high standards required in battery manufacturing. As the demand for lithium batteries continues to rise, driven by the growth in electric vehicles, renewable energy storage, and portable electronics, the need for efficient and reliable welding solutions has become more pronounced. Full automatic laser welding machines offer several advantages, including reduced labor costs, enhanced production efficiency, and improved product quality. They utilize advanced laser technology to create strong, durable welds that are essential for the performance and safety of lithium batteries. The market for these machines is expanding globally, with significant investments in research and development to enhance their capabilities and adapt to the evolving needs of the battery industry. As manufacturers strive to meet the increasing demand for lithium batteries, the adoption of full automatic laser welding machines is expected to grow, making them a critical component in the battery production process.

Fiber Lasers, Solid State Lasers, Other in the Global Full Automatic Laser Welding Machine for Lithium Battery Market:

Fiber lasers, solid-state lasers, and other types of lasers play a pivotal role in the Global Full Automatic Laser Welding Machine for Lithium Battery Market. Fiber lasers are renowned for their efficiency and precision, making them a popular choice in the industry. They operate by using a fiber optic cable to deliver the laser beam, which allows for high-quality welds with minimal heat distortion. This is particularly important in battery manufacturing, where maintaining the integrity of the materials is crucial. Fiber lasers are also known for their low maintenance requirements and long operational life, which contribute to their cost-effectiveness. Solid-state lasers, on the other hand, use a solid gain medium, such as a crystal or glass, to produce the laser beam. They are valued for their versatility and ability to handle a wide range of materials, making them suitable for various applications within the battery manufacturing process. Solid-state lasers are capable of producing high-energy beams, which are essential for welding thicker materials or creating deeper welds. This makes them an ideal choice for applications that require robust and durable welds. Other types of lasers, such as CO2 lasers and diode lasers, also find applications in the market, each offering unique advantages. CO2 lasers, for example, are known for their ability to cut and weld non-metallic materials, which can be beneficial in certain battery components. Diode lasers, with their compact size and high efficiency, are often used in applications where space and energy consumption are critical considerations. The choice of laser technology depends on various factors, including the specific requirements of the welding application, the materials involved, and the desired production outcomes. As the demand for lithium batteries continues to grow, manufacturers are increasingly investing in advanced laser technologies to enhance their production capabilities and meet the stringent quality standards of the industry. The integration of these laser technologies into full automatic laser welding machines is driving innovation and efficiency in the battery manufacturing process, enabling manufacturers to produce high-quality batteries at scale.

Power Battery, Energy Storage Battery, Others in the Global Full Automatic Laser Welding Machine for Lithium Battery Market:

The usage of Global Full Automatic Laser Welding Machines for Lithium Battery Market extends across various applications, including power batteries, energy storage batteries, and other specialized battery types. In the realm of power batteries, which are primarily used in electric vehicles, these machines play a crucial role in ensuring the structural integrity and performance of the battery packs. The precision and consistency offered by automatic laser welding machines are essential for creating strong, reliable connections between battery cells, which directly impact the overall efficiency and safety of electric vehicles. As the automotive industry continues to shift towards electrification, the demand for high-quality power batteries is on the rise, driving the adoption of advanced welding technologies. In the energy storage sector, full automatic laser welding machines are used to assemble batteries that store energy from renewable sources such as solar and wind. These batteries require robust and durable welds to withstand the demanding conditions of energy storage systems, including frequent charge and discharge cycles. The ability of laser welding machines to produce high-quality welds with minimal heat input is particularly beneficial in this context, as it helps preserve the integrity of the battery materials and extend their lifespan. Beyond power and energy storage batteries, these machines are also used in the production of batteries for consumer electronics, medical devices, and other specialized applications. The versatility of laser welding technology allows manufacturers to tailor the welding process to meet the specific requirements of different battery types, ensuring optimal performance and reliability. As the demand for lithium batteries continues to grow across various industries, the role of full automatic laser welding machines in the production process is becoming increasingly important. Manufacturers are leveraging these machines to enhance their production capabilities, improve product quality, and meet the evolving needs of the market.

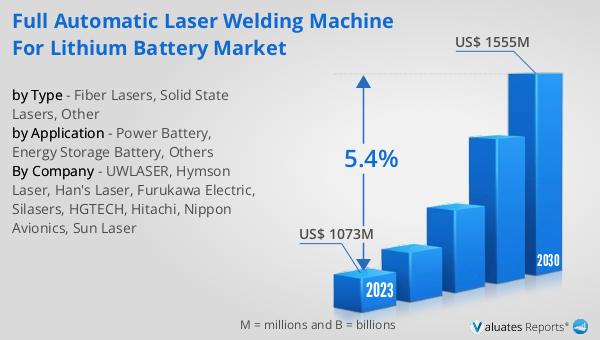

Global Full Automatic Laser Welding Machine for Lithium Battery Market Outlook:

In 2023, the global market for Full Automatic Laser Welding Machines for Lithium Batteries was valued at approximately $1,073 million. This market is projected to grow significantly, reaching an estimated value of $1,555 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 5.4% over the forecast period from 2024 to 2030. The increasing demand for lithium batteries, driven by the rise in electric vehicles, renewable energy storage solutions, and portable electronic devices, is a key factor contributing to this market expansion. As manufacturers strive to enhance production efficiency and product quality, the adoption of full automatic laser welding machines is expected to increase. These machines offer several advantages, including precision, speed, and consistency, which are essential for meeting the high standards required in battery manufacturing. The market's growth is also supported by ongoing advancements in laser technology, which are enabling manufacturers to develop more efficient and versatile welding solutions. As the industry continues to evolve, the global market for Full Automatic Laser Welding Machines for Lithium Batteries is poised for sustained growth, driven by the increasing demand for high-quality, reliable battery solutions across various applications.

| Report Metric | Details |

| Report Name | Full Automatic Laser Welding Machine for Lithium Battery Market |

| Accounted market size in 2023 | US$ 1073 million |

| Forecasted market size in 2030 | US$ 1555 million |

| CAGR | 5.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | UWLASER, Hymson Laser, Han's Laser, Furukawa Electric, Silasers, HGTECH, Hitachi, Nippon Avionics, Sun Laser |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |