What is Global SBR for Lithium Battery Adhesives Market?

The Global SBR for Lithium Battery Adhesives Market refers to the worldwide market for Styrene-Butadiene Rubber (SBR) used in adhesives specifically designed for lithium batteries. SBR is a synthetic rubber that provides excellent adhesive properties, making it ideal for use in lithium battery manufacturing. These adhesives are crucial for ensuring the structural integrity and performance of lithium batteries, which are widely used in various applications such as electric vehicles, consumer electronics, and energy storage systems. The market for SBR in lithium battery adhesives is driven by the increasing demand for high-performance batteries, advancements in battery technology, and the growing adoption of electric vehicles. As the demand for lithium batteries continues to rise, the need for reliable and efficient adhesives like SBR is expected to grow, making this market an important segment within the broader battery materials industry.

SBR, E-SBR, S-SBR in the Global SBR for Lithium Battery Adhesives Market:

SBR, or Styrene-Butadiene Rubber, is a synthetic rubber that is widely used in various applications due to its excellent properties such as high abrasion resistance, good aging stability, and strong adhesive capabilities. In the context of the Global SBR for Lithium Battery Adhesives Market, SBR plays a crucial role in ensuring the performance and durability of lithium batteries. There are two main types of SBR used in this market: Emulsion SBR (E-SBR) and Solution SBR (S-SBR). E-SBR is produced through an emulsion polymerization process, which results in a rubber with good mechanical properties and cost-effectiveness. It is commonly used in applications where high abrasion resistance and good aging stability are required. On the other hand, S-SBR is produced through a solution polymerization process, which allows for better control over the polymer structure and results in a rubber with superior performance characteristics. S-SBR offers enhanced properties such as improved tensile strength, better heat resistance, and lower rolling resistance, making it ideal for high-performance applications. In the Global SBR for Lithium Battery Adhesives Market, both E-SBR and S-SBR are used to meet the specific requirements of different battery applications. E-SBR is often used in applications where cost-effectiveness and good overall performance are important, while S-SBR is preferred for high-performance applications where superior properties are required. The choice between E-SBR and S-SBR depends on factors such as the specific requirements of the battery, the desired performance characteristics, and the cost considerations. Overall, the use of SBR in lithium battery adhesives is essential for ensuring the performance, durability, and reliability of lithium batteries, which are critical for various applications such as electric vehicles, consumer electronics, and energy storage systems.

Single Layer Lithium Battery, Double Layer Lithium Battery in the Global SBR for Lithium Battery Adhesives Market:

The usage of Global SBR for Lithium Battery Adhesives Market in single-layer lithium batteries and double-layer lithium batteries is crucial for ensuring the performance and reliability of these batteries. In single-layer lithium batteries, SBR adhesives are used to bond the various components of the battery, such as the electrodes and the separator, to ensure a strong and durable connection. The adhesive properties of SBR help to maintain the structural integrity of the battery, preventing delamination and ensuring consistent performance over the battery's lifespan. Additionally, SBR adhesives provide good thermal stability and resistance to chemical degradation, which are important for maintaining the safety and reliability of single-layer lithium batteries. In double-layer lithium batteries, SBR adhesives play a similar role in bonding the components of the battery, but with additional considerations for the increased complexity of the battery structure. Double-layer lithium batteries have multiple layers of electrodes and separators, which require strong and reliable adhesive bonds to ensure the overall performance and durability of the battery. SBR adhesives are used to bond these layers together, providing the necessary strength and stability to prevent delamination and ensure consistent performance. The adhesive properties of SBR also help to maintain the thermal stability and chemical resistance of double-layer lithium batteries, which are important for ensuring the safety and reliability of these batteries. Overall, the use of SBR adhesives in both single-layer and double-layer lithium batteries is essential for ensuring the performance, durability, and reliability of these batteries, which are critical for various applications such as electric vehicles, consumer electronics, and energy storage systems.

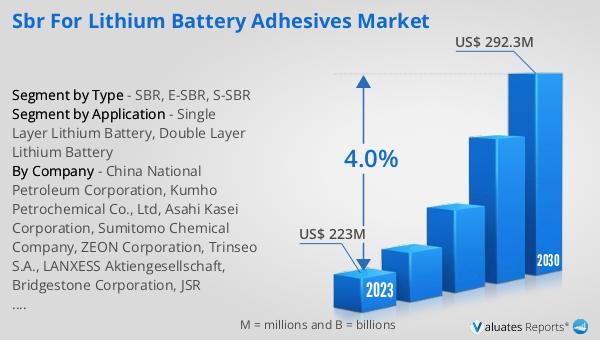

Global SBR for Lithium Battery Adhesives Market Outlook:

The global market for SBR used in lithium battery adhesives was valued at approximately US$ 223 million in 2023. This market is projected to grow significantly, reaching an estimated value of US$ 292.3 million by the year 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.0% during the forecast period from 2024 to 2030. The increasing demand for high-performance lithium batteries, driven by the growing adoption of electric vehicles, advancements in battery technology, and the need for efficient energy storage solutions, is a key factor contributing to the growth of this market. As the demand for lithium batteries continues to rise, the need for reliable and efficient adhesives like SBR is expected to grow, making this market an important segment within the broader battery materials industry. The projected growth of the Global SBR for Lithium Battery Adhesives Market reflects the increasing importance of high-quality adhesives in ensuring the performance, durability, and reliability of lithium batteries, which are critical for various applications such as electric vehicles, consumer electronics, and energy storage systems.

| Report Metric | Details |

| Report Name | SBR for Lithium Battery Adhesives Market |

| Accounted market size in 2023 | US$ 223 million |

| Forecasted market size in 2030 | US$ 292.3 million |

| CAGR | 4.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | China National Petroleum Corporation, Kumho Petrochemical Co., Ltd, Asahi Kasei Corporation, Sumitomo Chemical Company, ZEON Corporation, Trinseo S.A., LANXESS Aktiengesellschaft, Bridgestone Corporation, JSR Corporation, The Goodyear Tire & Rubber Company, Sinopec, Zhejiang Vitile Co., Ltd, Jiangsu Shenhua Chemical Co., Ltd, Zhechen Rubber, Fujian FuXiang Chemical Co., Ltd, PJSC Nizhnekamsk, Chandra Asri, Lion Elastomer, SRI Group, Versalis, Michelin, SIBUR, LG Chemicals, Dynasol Elastomer |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |