What is Global Precision Medical Fiber Optic Component Machining Services Market?

The Global Precision Medical Fiber Optic Component Machining Services Market is a specialized sector that focuses on the precise manufacturing and machining of fiber optic components used in medical devices. These components are crucial for various medical applications, including diagnostics, imaging, and surgical procedures. The market involves the use of advanced technologies and machinery to ensure that the fiber optic components meet stringent medical standards and specifications. This precision is essential for the reliability and effectiveness of medical devices, which can directly impact patient outcomes. The market is driven by the increasing demand for minimally invasive surgical procedures, advancements in medical technology, and the growing prevalence of chronic diseases that require sophisticated diagnostic and therapeutic tools. Companies operating in this market offer a range of services, including cutting, drilling, and shaping fiber optic components to exact dimensions and tolerances. These services are critical for the development of high-performance medical devices that can deliver accurate and reliable results.

Metal Component Processing, Non-metallic Components Processing in the Global Precision Medical Fiber Optic Component Machining Services Market:

Metal Component Processing and Non-metallic Components Processing are two critical aspects of the Global Precision Medical Fiber Optic Component Machining Services Market. Metal Component Processing involves the machining of various metals such as stainless steel, titanium, and aluminum, which are commonly used in medical devices due to their strength, durability, and biocompatibility. This process includes techniques like CNC machining, laser cutting, and electrochemical machining to achieve the desired shapes and sizes with high precision. The metal components are often used in the structural parts of medical devices, such as housings, connectors, and support structures, where mechanical strength and stability are paramount. On the other hand, Non-metallic Components Processing focuses on materials like plastics, ceramics, and composites, which are used for their lightweight, flexibility, and insulating properties. Techniques such as injection molding, 3D printing, and ultrasonic machining are employed to create intricate and delicate components that are essential for the optical and electronic functions of medical devices. Non-metallic components are often used in parts like lenses, casings, and insulation layers, where precision and material properties are crucial for the device's performance. Both metal and non-metallic component processing require a high level of expertise and advanced machinery to meet the stringent quality standards of the medical industry. The integration of these components into fiber optic systems enhances the functionality and reliability of medical devices, enabling them to perform complex tasks with high accuracy. The demand for these services is driven by the continuous advancements in medical technology, the need for customized solutions, and the growing emphasis on patient safety and outcomes. Companies in this market invest heavily in research and development to innovate and improve their machining processes, ensuring that they can meet the evolving needs of the medical industry. The collaboration between medical device manufacturers and machining service providers is crucial for the successful development and commercialization of new medical technologies. This synergy helps in addressing the challenges of miniaturization, precision, and biocompatibility, which are essential for the next generation of medical devices.

Medical, Telecom Fiber in the Global Precision Medical Fiber Optic Component Machining Services Market:

The usage of Global Precision Medical Fiber Optic Component Machining Services Market extends to various areas, including Medical and Telecom Fiber. In the medical field, these services are vital for the development of advanced diagnostic and therapeutic devices. Fiber optic components are used in endoscopes, which allow doctors to view inside the body with minimal invasion, leading to quicker diagnoses and less recovery time for patients. They are also used in surgical instruments that require high precision and reliability, such as laser scalpels and robotic surgery tools. The precision machining of these components ensures that they meet the stringent standards required for medical applications, providing accurate and reliable performance. In the telecom fiber sector, precision machining services are essential for the production of fiber optic cables and connectors that form the backbone of modern communication networks. These components need to be manufactured with high precision to ensure optimal signal transmission and minimal loss. The demand for high-speed internet and the expansion of telecom networks drive the need for advanced fiber optic components, which in turn fuels the growth of the machining services market. The precision and reliability of these components are crucial for maintaining the performance and efficiency of telecom networks, enabling seamless communication and data transfer. The integration of fiber optic technology in both medical and telecom sectors highlights the importance of precision machining services in advancing these industries. The continuous innovation and development in machining techniques ensure that the components meet the evolving needs of these sectors, contributing to their growth and advancement.

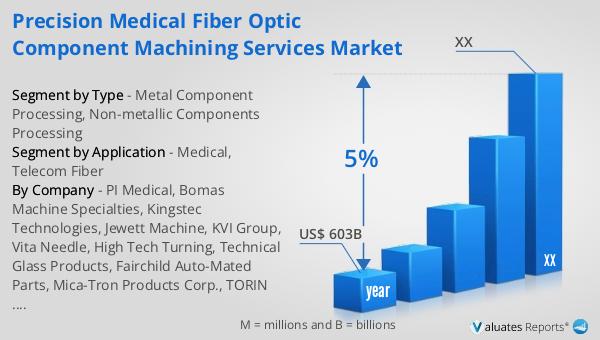

Global Precision Medical Fiber Optic Component Machining Services Market Outlook:

According to our research, the global market for medical devices is projected to reach approximately US$ 603 billion by the year 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including the increasing prevalence of chronic diseases, advancements in medical technology, and the rising demand for minimally invasive surgical procedures. The market's expansion reflects the growing need for sophisticated diagnostic and therapeutic tools that can improve patient outcomes and enhance the efficiency of healthcare delivery. Companies operating in this market are continuously investing in research and development to innovate and improve their products, ensuring that they meet the stringent quality standards required for medical applications. The collaboration between medical device manufacturers and machining service providers plays a crucial role in the successful development and commercialization of new medical technologies. This synergy helps in addressing the challenges of miniaturization, precision, and biocompatibility, which are essential for the next generation of medical devices. The market's growth also highlights the importance of precision machining services in the development of high-performance medical devices that can deliver accurate and reliable results.

| Report Metric | Details |

| Report Name | Precision Medical Fiber Optic Component Machining Services Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | PI Medical, Bomas Machine Specialties, Kingstec Technologies, Jewett Machine, KVI Group, Vita Needle, High Tech Turning, Technical Glass Products, Fairchild Auto-Mated Parts, Mica-Tron Products Corp., TORIN Products, Karl Gschwind Machine Works, Optics Technology, Northern Precision, Delaware Metals, Milco Wire Edm, STC Industries, AVF Screw Machine |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |