What is Global Medical Component Electrical Discharge Machining (EDM) Services Market?

Global Medical Component Electrical Discharge Machining (EDM) Services Market is a specialized sector within the broader medical device manufacturing industry. EDM is a precision manufacturing process that uses electrical discharges or sparks to shape metal components. This technique is particularly valuable in the medical field because it allows for the creation of complex and intricate parts that are often required in medical devices. These components can range from tiny surgical instruments to intricate parts of medical implants. The global market for these services is driven by the increasing demand for high-precision medical devices, advancements in medical technology, and the growing healthcare needs of an aging population. Companies offering EDM services are continually innovating to meet the stringent quality and precision standards required in the medical industry. This market is characterized by a high level of expertise and specialization, with service providers often working closely with medical device manufacturers to develop custom solutions. The global reach of this market means that companies can serve clients from various regions, contributing to the overall growth and development of the medical device industry.

Etch Metal, Cutting Shape in the Global Medical Component Electrical Discharge Machining (EDM) Services Market:

Etching metal and cutting shapes using Electrical Discharge Machining (EDM) services in the global medical component market involves a highly specialized process that is essential for creating precise and intricate medical components. EDM works by using electrical discharges or sparks to erode material from a workpiece, allowing for the creation of complex shapes and fine details that would be difficult or impossible to achieve with traditional machining methods. This process is particularly useful for working with hard metals and alloys that are commonly used in medical devices, such as stainless steel, titanium, and cobalt-chrome. These materials are chosen for their strength, biocompatibility, and resistance to corrosion, making them ideal for use in medical implants, surgical instruments, and other critical medical components. The ability to etch and cut these materials with high precision is crucial for ensuring the performance and safety of medical devices. EDM allows for the creation of features such as tiny holes, intricate patterns, and sharp edges, which are often required in medical components. For example, surgical instruments may need to have very fine tips or edges to perform delicate procedures, while implants may require complex geometries to fit precisely within the human body. The precision of EDM also helps to minimize material waste and reduce the need for additional finishing processes, which can save time and costs in the manufacturing process. In addition to metals, EDM can also be used to work with certain non-metal materials, such as ceramics and composites, which are increasingly being used in medical devices for their unique properties. The versatility of EDM makes it a valuable tool for medical device manufacturers, allowing them to create a wide range of components with the exact specifications needed for their applications. As the demand for advanced medical devices continues to grow, the role of EDM in the global medical component market is likely to become even more important. Companies that offer EDM services are continually investing in new technologies and techniques to improve the precision, efficiency, and capabilities of their processes. This includes the development of advanced EDM machines with higher accuracy and faster processing speeds, as well as the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software to optimize the machining process. By staying at the forefront of these advancements, EDM service providers can help medical device manufacturers meet the increasing demands for high-quality, reliable, and innovative medical components.

Metal, Non-metal in the Global Medical Component Electrical Discharge Machining (EDM) Services Market:

The usage of Global Medical Component Electrical Discharge Machining (EDM) Services Market in both metal and non-metal applications is extensive and varied, reflecting the diverse needs of the medical device industry. In metal applications, EDM is primarily used to machine hard and tough materials that are difficult to process using conventional methods. Metals such as stainless steel, titanium, and cobalt-chrome are commonly used in medical devices due to their strength, durability, and biocompatibility. EDM allows for the precise machining of these materials, enabling the creation of complex shapes and fine details that are essential for medical components. For example, surgical instruments often require very sharp edges and fine tips to perform delicate procedures, while implants need to have precise geometries to fit accurately within the human body. The precision of EDM ensures that these components meet the stringent quality and performance standards required in the medical field. Additionally, EDM can be used to create micro-sized features, such as tiny holes and intricate patterns, which are often needed in advanced medical devices. In non-metal applications, EDM is used to machine materials such as ceramics and composites, which are increasingly being used in medical devices for their unique properties. Ceramics, for example, are known for their hardness, wear resistance, and biocompatibility, making them ideal for use in dental implants, joint replacements, and other medical applications. EDM allows for the precise machining of ceramics, enabling the creation of complex shapes and fine details that are difficult to achieve with traditional methods. Composites, which are made from a combination of materials, offer a range of properties that can be tailored to specific medical applications. For example, carbon fiber composites are lightweight and strong, making them suitable for use in prosthetics and other medical devices. EDM can be used to machine these materials with high precision, ensuring that the final components meet the required specifications. The versatility of EDM in both metal and non-metal applications makes it a valuable tool for medical device manufacturers. By using EDM, manufacturers can create a wide range of components with the exact specifications needed for their applications, ensuring the performance and safety of their products. As the demand for advanced medical devices continues to grow, the role of EDM in the global medical component market is likely to become even more important. Companies that offer EDM services are continually investing in new technologies and techniques to improve the precision, efficiency, and capabilities of their processes. This includes the development of advanced EDM machines with higher accuracy and faster processing speeds, as well as the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software to optimize the machining process. By staying at the forefront of these advancements, EDM service providers can help medical device manufacturers meet the increasing demands for high-quality, reliable, and innovative medical components.

Global Medical Component Electrical Discharge Machining (EDM) Services Market Outlook:

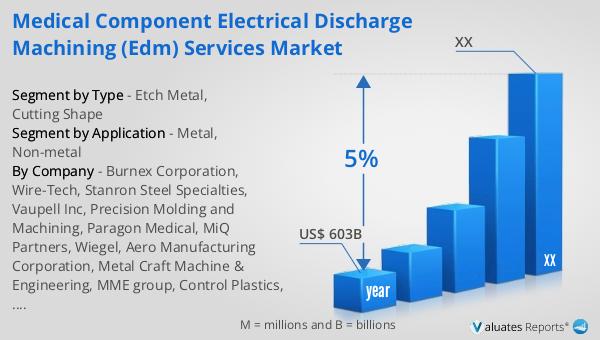

Based on our research, the global market for medical devices is projected to reach approximately $603 billion by the year 2023, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by several factors, including the increasing prevalence of chronic diseases, advancements in medical technology, and the growing demand for minimally invasive surgical procedures. The aging global population is also a significant contributor to the rising demand for medical devices, as older individuals typically require more medical care and interventions. Additionally, the expansion of healthcare infrastructure in emerging markets is expected to further boost the demand for medical devices. Companies operating in this market are continually innovating to develop new and improved products that meet the evolving needs of healthcare providers and patients. This includes the development of advanced diagnostic equipment, wearable medical devices, and smart healthcare solutions that leverage the latest technologies such as artificial intelligence and the Internet of Things (IoT). As a result, the global medical device market is poised for significant growth in the coming years, offering numerous opportunities for companies that can effectively navigate the competitive landscape and meet the increasing demand for high-quality medical devices.

| Report Metric | Details |

| Report Name | Medical Component Electrical Discharge Machining (EDM) Services Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Burnex Corporation, Wire-Tech, Stanron Steel Specialties, Vaupell Inc, Precision Molding and Machining, Paragon Medical, MiQ Partners, Wiegel, Aero Manufacturing Corporation, Metal Craft Machine & Engineering, MME group, Control Plastics, Cox Machine, Innovent Technologies, Decatur Mold Tool & Engineering, Prototek, Component Engineers, Remington Medical, Dexter Magnetic Technologies, Twigg Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |