What is Global Pharmaceutical SLS Printers Market?

The Global Pharmaceutical SLS Printers Market refers to the market for Selective Laser Sintering (SLS) printers specifically used in the pharmaceutical industry. SLS is a type of 3D printing technology that uses a laser to sinter powdered material into a solid structure. In the pharmaceutical sector, these printers are utilized for various applications, including the creation of complex drug delivery systems, personalized medicine, and the rapid prototyping of medical devices. The market for these specialized printers is growing due to the increasing demand for customized and efficient pharmaceutical solutions. Pharmaceutical companies, hospitals, and laboratories are investing in SLS printers to enhance their research and development capabilities, improve patient outcomes, and streamline manufacturing processes. The technology offers significant advantages such as high precision, the ability to create intricate designs, and the use of biocompatible materials, making it a valuable tool in modern pharmaceutical practices. As the pharmaceutical industry continues to evolve, the adoption of SLS printers is expected to rise, driven by the need for innovation and efficiency in drug development and production.

Below 100 W/CO2, Above 100 W/CO2 in the Global Pharmaceutical SLS Printers Market:

In the Global Pharmaceutical SLS Printers Market, the power output of the printers is a critical factor that influences their performance and suitability for different applications. SLS printers are generally categorized based on their laser power, with two primary segments being Below 100 W/CO2 and Above 100 W/CO2. Printers with a laser power Below 100 W/CO2 are typically used for applications that require high precision and fine detail. These printers are ideal for creating small, intricate components such as drug delivery systems, micro-needles, and other medical devices that need to be highly accurate and biocompatible. The lower power output ensures that the material is sintered gently, reducing the risk of damaging sensitive pharmaceutical compounds. On the other hand, printers with a laser power Above 100 W/CO2 are used for applications that require higher throughput and the ability to process larger volumes of material. These printers are suitable for manufacturing larger components, such as prosthetics, implants, and other medical devices that need to be robust and durable. The higher power output allows for faster sintering of the material, making the production process more efficient. Both categories of SLS printers play a crucial role in the pharmaceutical industry, offering unique advantages depending on the specific requirements of the application. The choice between Below 100 W/CO2 and Above 100 W/CO2 printers depends on factors such as the complexity of the design, the type of material being used, and the desired production speed. As the demand for personalized medicine and advanced medical devices continues to grow, the need for both types of SLS printers is expected to increase, driving innovation and efficiency in the pharmaceutical sector.

Pharmaceutical Company, Hospital, Laboratory in the Global Pharmaceutical SLS Printers Market:

The usage of Global Pharmaceutical SLS Printers Market in pharmaceutical companies, hospitals, and laboratories is diverse and impactful. In pharmaceutical companies, SLS printers are primarily used for research and development purposes. They enable the rapid prototyping of new drug delivery systems, allowing researchers to test and refine their designs quickly. This accelerates the drug development process, reducing the time and cost associated with bringing new medications to market. Additionally, SLS printers are used to create customized dosage forms, such as tablets and capsules, tailored to individual patient needs. This level of customization is particularly beneficial for patients with unique medical conditions or those requiring specific dosages. In hospitals, SLS printers are used to produce patient-specific medical devices and implants. For example, surgeons can create custom prosthetics and implants that perfectly match a patient's anatomy, improving the fit and function of these devices. This personalized approach enhances patient outcomes and reduces the risk of complications. Hospitals also use SLS printers to create surgical guides and models, which assist surgeons in planning and executing complex procedures with greater precision. In laboratories, SLS printers are used for a wide range of applications, including the creation of experimental models, the production of laboratory equipment, and the development of new materials. Researchers can use SLS printers to fabricate complex structures that would be difficult or impossible to create using traditional manufacturing methods. This capability opens up new possibilities for scientific exploration and innovation. Overall, the adoption of SLS printers in pharmaceutical companies, hospitals, and laboratories is driving significant advancements in medical research, patient care, and manufacturing efficiency.

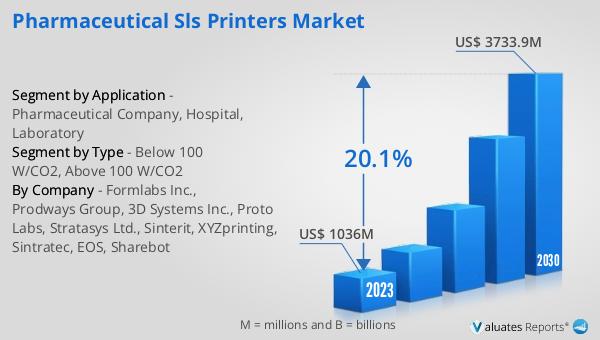

Global Pharmaceutical SLS Printers Market Outlook:

The global Pharmaceutical SLS Printers market was valued at US$ 1036 million in 2023 and is anticipated to reach US$ 3733.9 million by 2030, witnessing a CAGR of 20.1% during the forecast period 2024-2030. The global pharmaceutical market is 1475 billion USD in 2022, growing at a CAGR of 5% during the next six years. In comparison, the chemical drug market is estimated to increase from 1005 billion in 2018 to 1094 billion U.S. dollars in 2022. This significant growth in the Pharmaceutical SLS Printers market highlights the increasing demand for advanced manufacturing technologies in the pharmaceutical industry. The ability of SLS printers to produce highly precise and customized medical devices and drug delivery systems is driving their adoption across various sectors. As pharmaceutical companies, hospitals, and laboratories continue to seek innovative solutions to improve patient outcomes and streamline production processes, the market for SLS printers is expected to expand rapidly. The growing emphasis on personalized medicine and the need for efficient, cost-effective manufacturing methods are key factors contributing to the market's robust growth.

| Report Metric | Details |

| Report Name | Pharmaceutical SLS Printers Market |

| Accounted market size in 2023 | US$ 1036 million |

| Forecasted market size in 2030 | US$ 3733.9 million |

| CAGR | 20.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Formlabs Inc., Prodways Group, 3D Systems Inc., Proto Labs, Stratasys Ltd., Sinterit, XYZprinting, Sintratec, EOS, Sharebot |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |