What is Global Industrial SLS 3D Printers Market?

The Global Industrial SLS 3D Printers Market refers to the worldwide market for Selective Laser Sintering (SLS) 3D printers used in industrial applications. SLS is a type of additive manufacturing technology that uses a laser to sinter powdered material, binding it together to create a solid structure. This market encompasses a variety of industries that utilize SLS 3D printers for producing complex and high-precision parts. The technology is known for its ability to produce durable and functional prototypes, as well as end-use products, with a high degree of accuracy and detail. The global market for these printers is driven by the increasing demand for rapid prototyping, customization, and the production of complex geometries that are difficult to achieve with traditional manufacturing methods. The versatility of SLS 3D printing in working with different materials such as metals, plastics, and ceramics further broadens its application scope across various sectors. As industries continue to seek efficient and cost-effective manufacturing solutions, the adoption of SLS 3D printing technology is expected to grow, contributing to the expansion of the global market.

Metal Printing, Plastic Printing, Ceramic Printing in the Global Industrial SLS 3D Printers Market:

Metal printing, plastic printing, and ceramic printing are three primary applications of SLS 3D printing technology in the global industrial market. Metal printing using SLS technology involves the use of metal powders such as aluminum, titanium, and stainless steel. This process is highly valued in industries like aerospace and automotive, where the production of lightweight, strong, and heat-resistant components is crucial. Metal SLS 3D printing allows for the creation of complex geometries and internal structures that are not possible with traditional manufacturing methods, leading to significant advancements in product performance and efficiency. Plastic printing, on the other hand, utilizes thermoplastic powders such as nylon, polyamide, and TPU (thermoplastic polyurethane). This application is widely used in consumer electronics, medical devices, and automotive parts due to the material's flexibility, durability, and cost-effectiveness. Plastic SLS 3D printing is ideal for producing functional prototypes, end-use parts, and customized products with intricate designs. Ceramic printing with SLS technology involves the use of ceramic powders like alumina, zirconia, and silicon carbide. This application is particularly beneficial in industries that require high-temperature resistance, electrical insulation, and wear resistance, such as aerospace, medical, and heavy industry. Ceramic SLS 3D printing enables the production of complex shapes and fine details that are challenging to achieve with conventional ceramic manufacturing techniques. The ability to print with these diverse materials highlights the versatility and broad applicability of SLS 3D printing technology in the global industrial market. Each material offers unique properties and benefits, making SLS 3D printing a valuable tool for innovation and efficiency across various sectors.

Automotive, Aerospace, Medical and Healthcare, Consumer Electronics, Military, Heavy Industry in the Global Industrial SLS 3D Printers Market:

The usage of Global Industrial SLS 3D Printers Market spans several key areas, including automotive, aerospace, medical and healthcare, consumer electronics, military, and heavy industry. In the automotive sector, SLS 3D printing is used for rapid prototyping, production of lightweight components, and customization of parts. This technology allows automotive manufacturers to quickly iterate designs, reduce development time, and produce complex geometries that enhance vehicle performance and fuel efficiency. In the aerospace industry, SLS 3D printing is employed to create high-strength, lightweight components that can withstand extreme conditions. The ability to produce intricate parts with reduced material waste and shorter lead times makes SLS 3D printing an invaluable tool for aerospace engineers. In the medical and healthcare field, SLS 3D printing is used to produce customized implants, prosthetics, and surgical instruments. The precision and biocompatibility of SLS-printed medical devices improve patient outcomes and enable personalized treatment solutions. In consumer electronics, SLS 3D printing is utilized for the production of complex and miniaturized components, housings, and prototypes. This technology supports the rapid development and iteration of electronic devices, leading to faster time-to-market and enhanced product innovation. In the military sector, SLS 3D printing is used to produce durable and lightweight components for defense equipment, vehicles, and weaponry. The ability to quickly produce and repair parts in the field enhances operational readiness and reduces downtime. In heavy industry, SLS 3D printing is employed to create robust and wear-resistant components for machinery and equipment. The technology's ability to produce complex shapes and internal structures improves the performance and longevity of industrial tools and parts. Overall, the versatility and precision of SLS 3D printing technology make it a valuable asset across these diverse industries, driving innovation and efficiency in manufacturing processes.

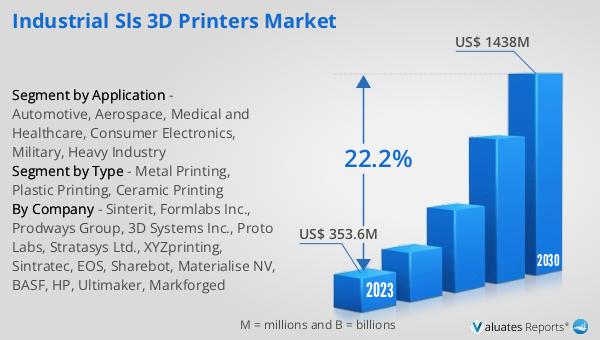

Global Industrial SLS 3D Printers Market Outlook:

The global Industrial SLS 3D Printers market was valued at US$ 353.6 million in 2023 and is anticipated to reach US$ 1438 million by 2030, witnessing a CAGR of 22.2% during the forecast period 2024-2030. This significant growth reflects the increasing adoption of SLS 3D printing technology across various industries due to its ability to produce high-quality, complex parts with precision and efficiency. The market's expansion is driven by the demand for rapid prototyping, customization, and the production of intricate geometries that traditional manufacturing methods struggle to achieve. As industries continue to seek innovative and cost-effective manufacturing solutions, the adoption of SLS 3D printing technology is expected to rise, contributing to the market's robust growth. The versatility of SLS 3D printing in working with different materials such as metals, plastics, and ceramics further broadens its application scope, making it a valuable tool for various sectors. The projected growth of the global Industrial SLS 3D Printers market underscores the technology's potential to revolutionize manufacturing processes and drive advancements in product development and performance.

| Report Metric | Details |

| Report Name | Industrial SLS 3D Printers Market |

| Accounted market size in 2023 | US$ 353.6 million |

| Forecasted market size in 2030 | US$ 1438 million |

| CAGR | 22.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sinterit, Formlabs Inc., Prodways Group, 3D Systems Inc., Proto Labs, Stratasys Ltd., XYZprinting, Sintratec, EOS, Sharebot, Materialise NV, BASF, HP, Ultimaker, Markforged |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |