What is Global Submersible Pump Market?

The global submersible pump market is a dynamic and essential segment of the broader pump industry, characterized by its ability to operate while fully submerged in water or other fluids. These pumps are designed to push fluid to the surface, making them highly efficient for various applications. The market is driven by the increasing demand for water and wastewater management, agricultural irrigation, and oil and gas extraction. Submersible pumps are favored for their efficiency, reliability, and ability to operate in challenging environments, such as deep wells or underwater conditions. Technological advancements have led to the development of more durable and energy-efficient models, further boosting their adoption. The market is also influenced by the growing need for infrastructure development and urbanization, particularly in emerging economies. As industries and municipalities seek sustainable solutions for fluid management, the global submersible pump market is poised for significant growth, offering opportunities for innovation and expansion. The market's competitive landscape includes a mix of established players and new entrants, all striving to meet the diverse needs of consumers across various sectors.

Plastic Submersible Pump, Cast Iron Submersible Pump, Stainless Steel Submersible Pump in the Global Submersible Pump Market:

In the global submersible pump market, different materials are used to manufacture pumps, each offering unique benefits and applications. Plastic submersible pumps are lightweight and resistant to corrosion, making them ideal for applications where chemical exposure is a concern. These pumps are often used in residential settings, aquariums, and small-scale water features due to their affordability and ease of installation. However, they may not be suitable for heavy-duty applications due to their lower durability compared to metal counterparts. Cast iron submersible pumps, on the other hand, are known for their robustness and longevity. They are commonly used in industrial and municipal applications where durability and reliability are paramount. Cast iron pumps can handle abrasive materials and high-pressure environments, making them suitable for sewage and wastewater management. Despite their strength, they are prone to corrosion if not properly maintained, especially in environments with high moisture or chemical exposure. Stainless steel submersible pumps offer a balance between durability and corrosion resistance. They are widely used in applications requiring both strength and resistance to harsh conditions, such as in the oil and gas industry, chemical processing, and marine environments. Stainless steel pumps are also favored in food and beverage industries due to their hygienic properties. While they are more expensive than plastic or cast iron pumps, their long lifespan and low maintenance requirements often justify the investment. Each type of submersible pump material caters to specific needs, and the choice depends on factors such as the nature of the fluid being pumped, environmental conditions, and budget constraints. As the global submersible pump market continues to evolve, manufacturers are focusing on enhancing the performance and efficiency of these pumps through material innovations and advanced engineering techniques.

Civil and Commercial Application, Agricultural Application, Industrial Application, Others in the Global Submersible Pump Market:

The global submersible pump market finds extensive usage across various sectors, each with unique requirements and challenges. In civil and commercial applications, submersible pumps are crucial for water supply, drainage, and sewage management. They are used in high-rise buildings, shopping malls, and residential complexes to ensure efficient water distribution and waste removal. These pumps are also employed in construction sites for dewatering purposes, helping to keep work areas dry and safe. In agricultural applications, submersible pumps play a vital role in irrigation systems, enabling farmers to efficiently water crops and maintain soil moisture levels. They are used in borewells and open wells to extract groundwater, ensuring a reliable water supply for agricultural activities. The pumps' ability to operate in submerged conditions makes them ideal for use in fields and remote areas where water sources are not easily accessible. In industrial applications, submersible pumps are used for a wide range of purposes, including chemical processing, oil and gas extraction, and mining operations. They are designed to handle corrosive and abrasive fluids, making them suitable for challenging industrial environments. These pumps are also used in cooling systems, fire protection, and wastewater treatment plants, where reliability and efficiency are critical. Other applications of submersible pumps include aquaculture, where they are used to maintain water quality in fish farms and hatcheries, and in environmental projects for groundwater monitoring and remediation. The versatility and adaptability of submersible pumps make them indispensable in various sectors, driving their demand and fostering innovation in the global market. As industries continue to seek efficient and sustainable solutions for fluid management, the role of submersible pumps is expected to expand further, offering new opportunities for growth and development.

Global Submersible Pump Market Outlook:

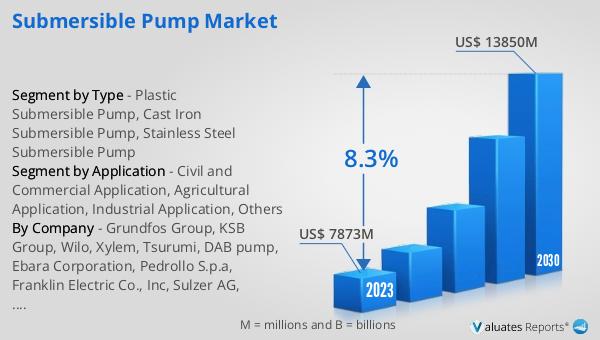

In 2024, the global submersible pump market was valued at approximately US$ 9,223 million, with projections indicating it could reach around US$ 15,990 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 8.3% during the forecast period from 2025 to 2031. Europe currently holds the largest share of the submersible pump market, accounting for about 28% of the total market share. China follows closely, with a market share of approximately 26%. The top three companies in the industry collectively occupy about 17% of the market share. This data highlights the competitive nature of the market, with both established players and emerging companies striving to capture a larger share. The market's growth is driven by increasing demand for efficient water and wastewater management solutions, as well as the need for reliable pumping systems in various industrial applications. As the market continues to expand, companies are focusing on innovation and technological advancements to meet the evolving needs of consumers and maintain their competitive edge. The global submersible pump market presents significant opportunities for growth and development, with key players investing in research and development to enhance product performance and efficiency.

| Report Metric | Details |

| Report Name | Submersible Pump Market |

| CAGR | 8.3% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Grundfos Group, KSB Group, Wilo, Xylem, Tsurumi, DAB pump, Ebara Corporation, Pedrollo S.p.a, Franklin Electric Co., Inc, Sulzer AG, SHIMGE, Kirloskar, Dongyin, Suprasuny, C.R.I PUPMS (Shanghai) Co.,Ltd, Saer Elettropompe S.p.a, Dafu, Yanshan Pump |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |