What is Global Expanded PTFE Membrane Market?

The Global Expanded PTFE (Polytetrafluoroethylene) Membrane Market is a specialized segment within the broader materials industry, focusing on the production and application of expanded PTFE membranes. These membranes are known for their exceptional properties, including high chemical resistance, thermal stability, and excellent filtration capabilities. Expanded PTFE membranes are created by expanding PTFE, a synthetic fluoropolymer, into a microporous structure. This process results in a material that is lightweight, durable, and highly versatile. The global market for these membranes is driven by their widespread use in various industries, such as automotive, electronics, medical, and energy sectors. The demand for expanded PTFE membranes is increasing due to their ability to provide effective solutions for filtration, venting, and protective applications. As industries continue to seek advanced materials that offer superior performance and reliability, the expanded PTFE membrane market is expected to grow, driven by technological advancements and the need for sustainable and efficient solutions. The market's growth is also supported by the increasing awareness of environmental concerns and the need for materials that can withstand harsh conditions while maintaining their integrity and performance.

Monolayer Film, Double Film, Other in the Global Expanded PTFE Membrane Market:

Monolayer films, double films, and other types of films play a significant role in the Global Expanded PTFE Membrane Market, each offering unique characteristics and applications. Monolayer films are single-layered membranes that provide a straightforward solution for applications requiring basic filtration and protection. These films are often used in situations where cost-effectiveness and simplicity are prioritized. They offer adequate performance for general applications but may not provide the enhanced features required for more demanding environments. On the other hand, double films consist of two layers of expanded PTFE, offering improved durability and performance. The dual-layer structure enhances the membrane's strength and resistance to environmental factors, making them suitable for more challenging applications. Double films are often used in industries where higher levels of protection and reliability are necessary, such as in automotive and industrial applications. The additional layer provides an extra barrier against contaminants and harsh conditions, ensuring the longevity and effectiveness of the membrane. Other types of films in the expanded PTFE membrane market include multi-layered and composite films, which combine different materials to achieve specific properties. These films are designed to meet the unique requirements of specialized applications, offering tailored solutions for complex challenges. Multi-layered films can provide superior filtration capabilities, enhanced chemical resistance, and improved thermal stability, making them ideal for use in high-performance environments. Composite films, on the other hand, integrate expanded PTFE with other materials to create membranes that offer a balance of properties, such as flexibility, strength, and permeability. These films are often used in applications where a combination of features is required to achieve optimal performance. The choice between monolayer, double, and other types of films depends on the specific needs of the application, including factors such as environmental conditions, performance requirements, and cost considerations. As the demand for advanced materials continues to grow, the expanded PTFE membrane market is expected to see further innovation and development in film technologies, providing industries with a wider range of options to meet their evolving needs.

Car, Consumer Electronics, New Energy, Medical, Other in the Global Expanded PTFE Membrane Market:

The Global Expanded PTFE Membrane Market finds extensive usage across various sectors, including automotive, consumer electronics, new energy, medical, and other industries. In the automotive sector, expanded PTFE membranes are used for venting applications, ensuring that automotive components such as headlights, sensors, and control units remain protected from moisture and contaminants. These membranes help maintain the performance and longevity of automotive parts by allowing air to pass through while preventing the ingress of water and dust. In consumer electronics, expanded PTFE membranes are utilized to protect sensitive electronic components from environmental factors. They are commonly used in devices such as smartphones, tablets, and wearable technology, where they provide a barrier against moisture and dust while allowing sound to pass through. This ensures that electronic devices remain functional and reliable, even in challenging conditions. The new energy sector also benefits from the use of expanded PTFE membranes, particularly in applications related to renewable energy sources such as solar panels and wind turbines. These membranes help protect critical components from environmental degradation, ensuring the efficiency and longevity of energy systems. In the medical field, expanded PTFE membranes are used in various applications, including medical implants, filtration devices, and protective clothing. Their biocompatibility and chemical resistance make them ideal for use in medical environments, where they provide reliable performance and protection. Other industries that utilize expanded PTFE membranes include industrial manufacturing, where they are used for filtration and separation processes, and the construction industry, where they provide weatherproofing and insulation solutions. The versatility and durability of expanded PTFE membranes make them a valuable material across a wide range of applications, driving their demand in the global market.

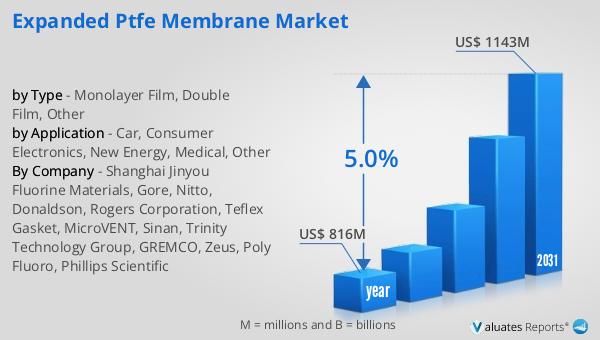

Global Expanded PTFE Membrane Market Outlook:

The global market for Expanded PTFE Membrane was valued at $816 million in 2024 and is anticipated to grow to a revised size of $1,143 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.0% during the forecast period. This growth trajectory highlights the increasing demand for expanded PTFE membranes across various industries, driven by their unique properties and versatile applications. As industries continue to seek materials that offer superior performance, durability, and environmental resistance, the expanded PTFE membrane market is poised for significant expansion. The projected growth in market size underscores the importance of these membranes in addressing the evolving needs of industries such as automotive, electronics, medical, and energy. The steady CAGR indicates a consistent increase in adoption and utilization of expanded PTFE membranes, as companies recognize their value in enhancing product performance and reliability. This market outlook reflects the ongoing advancements in membrane technology and the growing awareness of the benefits of using expanded PTFE membranes in diverse applications. As the market continues to evolve, it is expected to offer new opportunities for innovation and development, further solidifying the role of expanded PTFE membranes in the global materials industry.

| Report Metric | Details |

| Report Name | Expanded PTFE Membrane Market |

| Accounted market size in year | US$ 816 million |

| Forecasted market size in 2031 | US$ 1143 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Shanghai Jinyou Fluorine Materials, Gore, Nitto, Donaldson, Rogers Corporation, Teflex Gasket, MicroVENT, Sinan, Trinity Technology Group, GREMCO, Zeus, Poly Fluoro, Phillips Scientific |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |