What is Global Precipitated Synthetic Barium Sulfate Market?

The Global Precipitated Synthetic Barium Sulfate Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of barium sulfate that is synthetically precipitated. This compound is known for its high density, chemical inertness, and white opaque appearance, making it a valuable additive in various industrial applications. The market is driven by the demand for high-quality fillers and extenders in industries such as coatings, plastics, and rubber. The synthetic production process allows for the creation of barium sulfate with specific particle sizes and purity levels, catering to the diverse needs of different applications. As industries continue to seek materials that enhance product performance and reduce costs, the demand for precipitated synthetic barium sulfate is expected to grow. This market is characterized by technological advancements in production processes, which aim to improve the quality and efficiency of barium sulfate production. Additionally, environmental regulations and sustainability concerns are influencing market dynamics, as manufacturers strive to develop eco-friendly production methods. Overall, the Global Precipitated Synthetic Barium Sulfate Market plays a crucial role in supporting various industrial sectors by providing a reliable and versatile material that enhances product quality and performance.

Industrial Grade, Ultra-fine Grade, High Purity Grade in the Global Precipitated Synthetic Barium Sulfate Market:

In the Global Precipitated Synthetic Barium Sulfate Market, different grades of barium sulfate are produced to meet the specific requirements of various applications. Industrial Grade barium sulfate is commonly used in applications where high purity is not the primary concern, but rather the focus is on cost-effectiveness and functionality. This grade is often utilized in the production of paints, coatings, and plastics, where it serves as a filler to improve the physical properties of the final product. Industrial Grade barium sulfate is valued for its ability to enhance the durability, opacity, and brightness of coatings and plastics, making it a popular choice in these industries. Ultra-fine Grade barium sulfate, on the other hand, is characterized by its extremely small particle size, which allows for a smooth and uniform dispersion in various matrices. This grade is particularly important in applications where a high level of fineness is required, such as in the production of high-gloss paints and coatings. The ultra-fine particles help to achieve a smooth finish and improve the overall aesthetic appeal of the final product. Additionally, Ultra-fine Grade barium sulfate is used in the electronics industry, where it serves as a dielectric filler in capacitors and other electronic components. High Purity Grade barium sulfate is produced with a focus on achieving the highest level of purity possible. This grade is essential in applications where impurities could negatively impact the performance or safety of the final product. High Purity Grade barium sulfate is often used in the pharmaceutical industry, where it serves as a contrast agent in medical imaging procedures. Its high purity ensures that it does not interfere with the imaging process or cause any adverse reactions in patients. Furthermore, this grade is used in the production of optical glass and other high-tech applications, where the presence of impurities could compromise the quality and performance of the final product. The production of these different grades of barium sulfate involves advanced manufacturing processes that allow for precise control over particle size, purity, and other key characteristics. Manufacturers in the Global Precipitated Synthetic Barium Sulfate Market invest in research and development to continuously improve their production techniques and meet the evolving needs of their customers. As industries continue to demand materials that offer superior performance and cost-effectiveness, the development and production of specialized grades of barium sulfate will remain a critical focus for manufacturers in this market.

Coatings and Painting, Plastic and Rubber, Ink Industry, Other Industry in the Global Precipitated Synthetic Barium Sulfate Market:

The Global Precipitated Synthetic Barium Sulfate Market finds extensive usage across various industries, with its applications in coatings and painting, plastic and rubber, the ink industry, and other sectors being particularly noteworthy. In the coatings and painting industry, precipitated synthetic barium sulfate is used as a filler and extender to enhance the properties of paints and coatings. Its high density and chemical inertness make it an ideal choice for improving the opacity, brightness, and durability of coatings. By incorporating barium sulfate, manufacturers can produce coatings that offer better coverage and resistance to environmental factors, such as UV radiation and moisture. This results in longer-lasting and visually appealing finishes, which are highly valued in both architectural and industrial applications. In the plastic and rubber industry, precipitated synthetic barium sulfate is used as a reinforcing filler to improve the mechanical properties of plastic and rubber products. Its fine particle size and uniform distribution help to enhance the strength, stiffness, and impact resistance of these materials. Additionally, barium sulfate can improve the thermal stability and processability of plastics and rubber, making it easier to manufacture high-quality products. This is particularly important in the automotive and construction industries, where durable and reliable materials are essential. The ink industry also benefits from the use of precipitated synthetic barium sulfate, as it serves as a pigment extender and opacifying agent in various ink formulations. Its ability to improve the opacity and brightness of inks makes it a valuable additive in the production of high-quality printing inks. Barium sulfate helps to achieve vibrant and consistent colors, which are crucial for producing sharp and clear printed materials. Furthermore, its chemical inertness ensures that it does not react with other components in the ink, maintaining the stability and quality of the final product. Beyond these industries, precipitated synthetic barium sulfate is used in a range of other applications, including the production of adhesives, sealants, and ceramics. In adhesives and sealants, it acts as a filler to improve the viscosity and mechanical properties of the final product. In ceramics, barium sulfate is used as a fluxing agent to lower the melting point of ceramic materials, facilitating the manufacturing process. The versatility and performance-enhancing properties of precipitated synthetic barium sulfate make it a valuable material in these diverse applications, supporting the development of high-quality and innovative products across various industries.

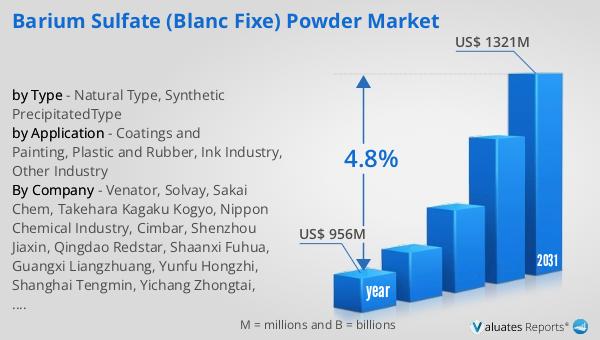

Global Precipitated Synthetic Barium Sulfate Market Outlook:

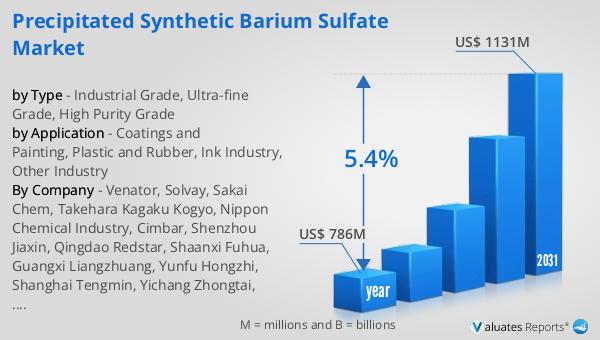

The global market for Precipitated Synthetic Barium Sulfate was valued at $786 million in 2024, and it is anticipated to grow significantly, reaching an estimated value of $1,131 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.4% over the forecast period. This upward trend is indicative of the increasing demand for high-quality barium sulfate across various industries, driven by its unique properties and versatility. The market's expansion is supported by the continuous advancements in production technologies, which enable manufacturers to produce barium sulfate with specific characteristics tailored to meet the diverse needs of different applications. As industries such as coatings, plastics, and pharmaceuticals continue to evolve and seek materials that enhance product performance and sustainability, the demand for precipitated synthetic barium sulfate is expected to rise. Additionally, the growing focus on environmental regulations and sustainability is influencing market dynamics, as manufacturers strive to develop eco-friendly production methods. This market outlook highlights the significant potential for growth and innovation within the Global Precipitated Synthetic Barium Sulfate Market, as it continues to play a crucial role in supporting various industrial sectors by providing a reliable and versatile material that enhances product quality and performance.

| Report Metric | Details |

| Report Name | Precipitated Synthetic Barium Sulfate Market |

| Accounted market size in year | US$ 786 million |

| Forecasted market size in 2031 | US$ 1131 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Venator, Solvay, Sakai Chem, Takehara Kagaku Kogyo, Nippon Chemical Industry, Cimbar, Shenzhou Jiaxin, Qingdao Redstar, Shaanxi Fuhua, Guangxi Liangzhuang, Yunfu Hongzhi, Shanghai Tengmin, Yichang Zhongtai, Foshan Anyi, Hebei Xinji Chem Group, Shanghai Yuejiang, Qingdao Yilite, Gongyi Shengda, Guangdong Yufeng, Hunan Hechuang, Jiangsu Qunxin, Zhushan Yanba |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |