What is Global Pharmaceutical Storage Cabinet Market?

The Global Pharmaceutical Storage Cabinet Market is a crucial segment within the healthcare industry, focusing on the storage solutions specifically designed for pharmaceuticals. These cabinets are essential for maintaining the integrity and efficacy of medications by providing a controlled environment that safeguards against temperature fluctuations, humidity, and contamination. The market encompasses a wide range of storage solutions, including refrigerated cabinets, ambient storage units, and specialized cabinets for hazardous materials. As the pharmaceutical industry continues to grow, driven by increasing demand for medications and advancements in drug development, the need for reliable storage solutions becomes more critical. These cabinets are used in various settings, such as hospitals, clinics, pharmacies, and research laboratories, ensuring that medications are stored safely and are readily accessible when needed. The market is influenced by factors such as technological advancements, regulatory requirements, and the growing emphasis on patient safety and medication efficacy. As a result, manufacturers are continually innovating to develop cabinets that meet the stringent standards of the pharmaceutical industry, offering features such as digital temperature controls, alarm systems, and secure locking mechanisms. The Global Pharmaceutical Storage Cabinet Market plays a vital role in the healthcare supply chain, ensuring that medications are stored properly and are effective when administered to patients.

Horizontal Storage Cabinet, Vertical Storage Cabinet in the Global Pharmaceutical Storage Cabinet Market:

In the Global Pharmaceutical Storage Cabinet Market, storage solutions are categorized into horizontal and vertical storage cabinets, each serving distinct purposes and offering unique benefits. Horizontal storage cabinets are designed with a wide, low-profile structure, making them ideal for storing large quantities of pharmaceuticals that require easy access and organization. These cabinets often feature multiple drawers or shelves, allowing for efficient categorization and retrieval of medications. The horizontal design is particularly beneficial in settings where space is not a constraint, such as large hospital pharmacies or research laboratories. They provide ample storage capacity and are often equipped with advanced features like temperature control systems, digital monitoring, and secure locking mechanisms to ensure the safety and integrity of stored pharmaceuticals. On the other hand, vertical storage cabinets are designed to maximize storage capacity in environments where floor space is limited. These cabinets are tall and narrow, making them suitable for use in smaller clinics, pharmacies, or hospital wards where space optimization is crucial. Vertical cabinets often come with adjustable shelves, allowing for flexible storage configurations to accommodate various sizes of pharmaceutical products. They are also equipped with features like temperature regulation, humidity control, and security systems to maintain the quality and safety of medications. Both horizontal and vertical storage cabinets are integral to the pharmaceutical storage market, catering to different needs and preferences of healthcare facilities. The choice between horizontal and vertical cabinets often depends on factors such as available space, the volume of pharmaceuticals to be stored, and specific storage requirements. In addition to their structural differences, both types of cabinets are designed with a focus on compliance with regulatory standards, ensuring that they meet the necessary guidelines for pharmaceutical storage. This includes maintaining appropriate temperature ranges, preventing contamination, and providing secure access to authorized personnel only. As the demand for pharmaceuticals continues to rise, driven by factors such as an aging population, increasing prevalence of chronic diseases, and advancements in drug development, the need for efficient and reliable storage solutions becomes more pronounced. Manufacturers in the Global Pharmaceutical Storage Cabinet Market are continually innovating to develop cabinets that not only meet the functional requirements of healthcare facilities but also enhance operational efficiency and patient safety. This includes the integration of smart technologies, such as IoT-enabled monitoring systems, which allow for real-time tracking of storage conditions and inventory management. By offering a range of storage solutions tailored to the diverse needs of the healthcare industry, the Global Pharmaceutical Storage Cabinet Market plays a crucial role in ensuring that medications are stored safely and effectively, ultimately contributing to improved patient outcomes.

Hospital, Clinic, Other in the Global Pharmaceutical Storage Cabinet Market:

The usage of Global Pharmaceutical Storage Cabinets is widespread across various healthcare settings, including hospitals, clinics, and other facilities, each with specific storage needs and requirements. In hospitals, pharmaceutical storage cabinets are essential for managing the vast array of medications required for patient care. Hospitals often have dedicated pharmacy departments that handle the procurement, storage, and distribution of medications throughout the facility. Storage cabinets in hospitals are designed to accommodate large volumes of pharmaceuticals, ensuring that medications are readily available for patient treatment. These cabinets are equipped with advanced features such as temperature control, humidity regulation, and secure locking mechanisms to maintain the integrity and safety of stored medications. In addition to pharmacy departments, hospitals may also have storage cabinets located in individual wards or units, providing easy access to medications for healthcare professionals. Clinics, on the other hand, typically have smaller storage needs compared to hospitals but still require efficient and reliable storage solutions. Pharmaceutical storage cabinets in clinics are often used to store a limited range of medications, including vaccines, antibiotics, and other essential drugs. These cabinets are designed to optimize space utilization, often featuring vertical storage configurations to accommodate the limited floor space available in clinic settings. Clinics rely on these cabinets to ensure that medications are stored at the appropriate temperature and are easily accessible for patient care. The secure storage of pharmaceuticals is particularly important in clinics, where medications may be administered directly to patients. Other healthcare facilities, such as long-term care facilities, research laboratories, and pharmacies, also utilize pharmaceutical storage cabinets to meet their specific storage needs. Long-term care facilities, for example, require storage solutions that can accommodate medications for residents over extended periods. These facilities often use storage cabinets with features like temperature monitoring and secure access to ensure the safety and efficacy of medications. Research laboratories, on the other hand, may require specialized storage cabinets for hazardous materials or experimental drugs, emphasizing the need for cabinets that offer precise temperature control and contamination prevention. Pharmacies, whether located within hospitals or operating independently, rely on pharmaceutical storage cabinets to manage their inventory and ensure that medications are stored safely and efficiently. The use of pharmaceutical storage cabinets across these various settings highlights the importance of having reliable and compliant storage solutions in place. As the demand for pharmaceuticals continues to grow, driven by factors such as an aging population, increasing prevalence of chronic diseases, and advancements in drug development, the need for efficient and reliable storage solutions becomes more pronounced. The Global Pharmaceutical Storage Cabinet Market plays a crucial role in ensuring that medications are stored safely and effectively, ultimately contributing to improved patient outcomes and the overall efficiency of healthcare delivery.

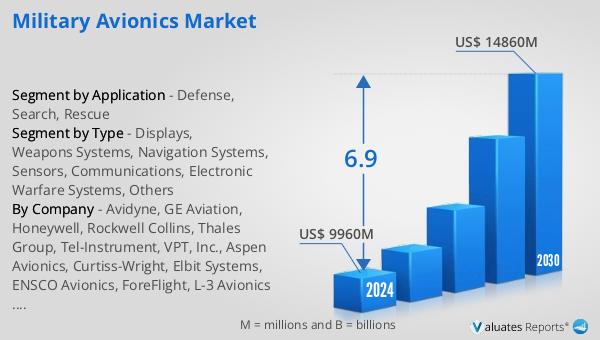

Global Pharmaceutical Storage Cabinet Market Outlook:

The outlook for the Global Pharmaceutical Storage Cabinet Market is closely tied to the broader trends in the pharmaceutical industry. In 2022, the global pharmaceutical market was valued at approximately 1,475 billion USD, with an expected compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for medications and the continuous advancements in drug development. In comparison, the chemical drug market has shown a steady increase, growing from 1,005 billion USD in 2018 to an estimated 1,094 billion USD in 2022. This growth in the pharmaceutical and chemical drug markets underscores the need for effective storage solutions to manage the expanding inventory of medications. As the pharmaceutical industry continues to evolve, driven by factors such as an aging population, the rise of chronic diseases, and technological advancements, the demand for reliable storage solutions becomes more critical. Pharmaceutical storage cabinets play a vital role in ensuring that medications are stored safely and effectively, maintaining their integrity and efficacy. The market for these cabinets is influenced by factors such as regulatory requirements, technological innovations, and the growing emphasis on patient safety and medication efficacy. Manufacturers are continually innovating to develop cabinets that meet the stringent standards of the pharmaceutical industry, offering features such as digital temperature controls, alarm systems, and secure locking mechanisms. The Global Pharmaceutical Storage Cabinet Market is poised to grow in tandem with the broader pharmaceutical industry, playing a crucial role in the healthcare supply chain and ensuring that medications are stored properly and are effective when administered to patients.

| Report Metric | Details |

| Report Name | Pharmaceutical Storage Cabinet Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Segment by Region |

|

| By Company | Adamus, Kaizen International, Proton Engineers, Sanitt Equipment & Machines, Sunmac Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |