What is Global Pneumatic Rotary Actuators Market?

The Global Pneumatic Rotary Actuators Market is a specialized segment within the broader industrial automation and control systems industry. Pneumatic rotary actuators are devices that convert energy from compressed air into rotary motion, which is essential for various mechanical applications. These actuators are widely used in industries where precise control of motion is required, such as manufacturing, automotive, and aerospace. The market for these actuators is driven by the increasing demand for automation in industrial processes, which enhances efficiency and reduces human error. Additionally, the growing emphasis on energy-efficient systems has led to the adoption of pneumatic actuators, as they are known for their reliability and low maintenance requirements. The market is characterized by a diverse range of products, including single-cylinder and multi-cylinder rotary actuators, each designed to meet specific operational needs. As industries continue to evolve and seek more advanced automation solutions, the demand for pneumatic rotary actuators is expected to grow, driven by technological advancements and the need for improved operational efficiency.

Single-cylinder Rotary Actuators, Multi-cylinders Rotary Actuators, Others in the Global Pneumatic Rotary Actuators Market:

Single-cylinder rotary actuators are a fundamental component of the Global Pneumatic Rotary Actuators Market. These actuators are designed to provide a simple yet effective solution for applications requiring limited rotational movement. They consist of a single cylinder that uses compressed air to produce a rotary motion, typically up to 180 degrees. This type of actuator is favored for its compact design, ease of installation, and cost-effectiveness, making it suitable for applications in industries such as packaging, material handling, and automotive manufacturing. Single-cylinder rotary actuators are often used in situations where space is limited, and precise control of movement is essential. They are known for their durability and ability to operate in harsh environments, which adds to their appeal in various industrial settings. On the other hand, multi-cylinder rotary actuators offer a more complex solution for applications requiring greater torque and rotational movement. These actuators consist of multiple cylinders working in tandem to produce a more powerful rotary motion, often exceeding 180 degrees. The design of multi-cylinder actuators allows for greater flexibility in terms of motion control, making them ideal for heavy-duty applications in industries such as oil and gas, mining, and construction. The ability to generate higher torque makes multi-cylinder actuators suitable for tasks that involve lifting, rotating, or positioning heavy loads. Additionally, these actuators are often equipped with advanced features such as adjustable stroke lengths and integrated feedback systems, which enhance their performance and adaptability to specific operational requirements. Beyond single and multi-cylinder configurations, the Global Pneumatic Rotary Actuators Market also includes other specialized types of actuators designed to meet unique industrial needs. These may include rack and pinion actuators, vane actuators, and scotch yoke actuators, each offering distinct advantages in terms of motion control and operational efficiency. Rack and pinion actuators, for example, are known for their high torque output and precise positioning capabilities, making them suitable for applications in robotics and automation. Vane actuators, on the other hand, are valued for their compact design and ability to provide continuous rotary motion, which is essential in applications such as conveyor systems and assembly lines. Scotch yoke actuators are often used in applications requiring high torque at the beginning and end of the stroke, such as valve control in the oil and gas industry. The diversity of products within the Global Pneumatic Rotary Actuators Market reflects the wide range of applications and industries that rely on these devices for efficient and reliable motion control. As technology continues to advance, the development of more sophisticated and versatile actuators is expected to drive further growth in the market, offering new opportunities for innovation and application across various sectors.

Construction, Oil & Gas, Metal & Mining, Agriculture, Industrial in the Global Pneumatic Rotary Actuators Market:

The usage of Global Pneumatic Rotary Actuators Market spans several key industries, each benefiting from the unique capabilities of these devices. In the construction industry, pneumatic rotary actuators are used in various applications, including the operation of heavy machinery, cranes, and lifting equipment. Their ability to provide precise control of motion and high torque output makes them ideal for tasks such as positioning and rotating construction materials. The durability and reliability of pneumatic actuators also make them suitable for use in harsh construction environments, where they can withstand dust, dirt, and extreme temperatures. In the oil and gas industry, pneumatic rotary actuators play a crucial role in the operation of valves and control systems. These actuators are used to regulate the flow of oil and gas through pipelines, ensuring safe and efficient transportation of these resources. The ability to provide precise control of valve positions is essential in maintaining the integrity of the pipeline system and preventing leaks or spills. Pneumatic actuators are also valued for their ability to operate in hazardous environments, where electrical devices may pose a risk of explosion. In the metal and mining industry, pneumatic rotary actuators are used in various applications, including the operation of conveyor systems, crushers, and material handling equipment. The ability to provide high torque output and precise control of motion is essential in these applications, where heavy loads and harsh operating conditions are common. Pneumatic actuators are also valued for their low maintenance requirements, which is a significant advantage in remote mining locations where access to maintenance services may be limited. In agriculture, pneumatic rotary actuators are used in various applications, including the operation of irrigation systems, grain handling equipment, and automated feeding systems. The ability to provide precise control of motion and reliable operation is essential in these applications, where efficiency and productivity are critical. Pneumatic actuators are also valued for their ability to operate in dusty and dirty environments, which are common in agricultural settings. In the industrial sector, pneumatic rotary actuators are used in a wide range of applications, including the operation of assembly lines, robotic systems, and material handling equipment. The ability to provide precise control of motion and high torque output is essential in these applications, where efficiency and productivity are critical. Pneumatic actuators are also valued for their reliability and low maintenance requirements, which contribute to the overall efficiency of industrial operations. The versatility and reliability of pneumatic rotary actuators make them an essential component in various industries, where they contribute to improved efficiency, productivity, and safety. As industries continue to evolve and seek more advanced automation solutions, the demand for pneumatic rotary actuators is expected to grow, driven by technological advancements and the need for improved operational efficiency.

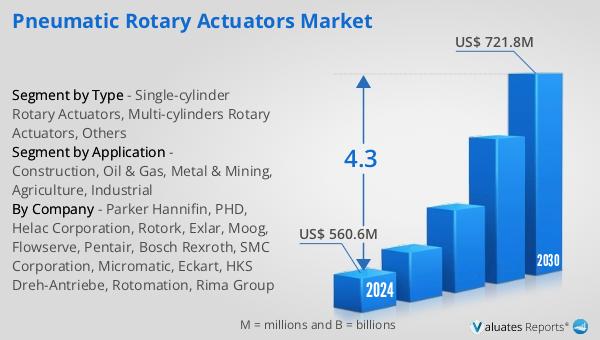

Global Pneumatic Rotary Actuators Market Outlook:

The outlook for the Global Pneumatic Rotary Actuators Market indicates a promising growth trajectory over the coming years. The market is anticipated to expand from a valuation of approximately US$ 560.6 million in 2024 to an estimated US$ 721.8 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 4.3% during the forecast period. This projected growth can be attributed to several factors, including the increasing demand for automation in various industries, the need for energy-efficient systems, and the ongoing advancements in actuator technology. As industries continue to prioritize efficiency and productivity, the adoption of pneumatic rotary actuators is likely to increase, driven by their ability to provide precise control of motion and reliable operation in diverse applications. The market's growth is also supported by the expanding industrial sector, particularly in emerging economies, where the demand for automation solutions is on the rise. Additionally, the development of more sophisticated and versatile actuators is expected to open new opportunities for innovation and application across various sectors, further driving the market's expansion. As a result, the Global Pneumatic Rotary Actuators Market is poised for significant growth, offering new opportunities for manufacturers and suppliers to capitalize on the increasing demand for advanced automation solutions.

| Report Metric | Details |

| Report Name | Pneumatic Rotary Actuators Market |

| Accounted market size in 2024 | US$ 560.6 million |

| Forecasted market size in 2030 | US$ 721.8 million |

| CAGR | 4.3 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Parker Hannifin, PHD, Helac Corporation, Rotork, Exlar, Moog, Flowserve, Pentair, Bosch Rexroth, SMC Corporation, Micromatic, Eckart, HKS Dreh-Antriebe, Rotomation, Rima Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |