What is Global Continuous Rotary Extrusion Equipment Market?

The Global Continuous Rotary Extrusion Equipment Market is a specialized segment within the broader machinery and equipment industry, focusing on the production and utilization of machinery designed for continuous rotary extrusion processes. This market is characterized by its ability to provide advanced solutions for the extrusion of various metals and alloys, which are essential in numerous industrial applications. Continuous rotary extrusion equipment is used to transform raw materials into desired shapes and profiles through a continuous process, which enhances efficiency and reduces waste. This equipment is particularly valued for its ability to produce high-quality extrusions with precise dimensions and excellent surface finishes. The market is driven by the increasing demand for lightweight and high-strength materials in industries such as automotive, aerospace, and construction. Additionally, technological advancements in extrusion machinery, coupled with the growing emphasis on energy efficiency and sustainability, are further propelling the market's growth. As industries continue to seek innovative solutions to meet evolving consumer demands and regulatory requirements, the Global Continuous Rotary Extrusion Equipment Market is poised to play a crucial role in shaping the future of manufacturing and material processing.

Curvilinear Type Continous Extrusion Machine, Radial Type Continous Extrusion Machine in the Global Continuous Rotary Extrusion Equipment Market:

Curvilinear Type Continuous Extrusion Machines and Radial Type Continuous Extrusion Machines are two prominent categories within the Global Continuous Rotary Extrusion Equipment Market, each offering unique advantages and applications. Curvilinear Type Continuous Extrusion Machines are designed to handle complex extrusion processes that require precise control over the material flow and shape. These machines are particularly suited for producing intricate profiles and components with varying cross-sections, making them ideal for industries such as automotive and aerospace, where precision and complexity are paramount. The curvilinear design allows for smooth and continuous material flow, minimizing the risk of defects and ensuring consistent quality. On the other hand, Radial Type Continuous Extrusion Machines are engineered to provide high throughput and efficiency, making them suitable for large-scale production environments. These machines are characterized by their radial configuration, which enables the simultaneous extrusion of multiple profiles or components. This design not only enhances productivity but also reduces operational costs by optimizing material usage and minimizing waste. Radial Type Continuous Extrusion Machines are commonly used in industries such as construction and infrastructure, where large volumes of standardized components are required. Both types of machines are integral to the continuous rotary extrusion process, offering distinct benefits that cater to the diverse needs of various industries. As the demand for advanced extrusion solutions continues to grow, manufacturers are investing in research and development to enhance the capabilities and performance of these machines. Innovations such as automation, digitalization, and the integration of smart technologies are transforming the landscape of continuous rotary extrusion, enabling manufacturers to achieve higher levels of precision, efficiency, and sustainability. The Global Continuous Rotary Extrusion Equipment Market is witnessing a shift towards more sophisticated and versatile machines that can adapt to the evolving demands of modern manufacturing. As industries strive to improve their production processes and meet stringent quality standards, the role of Curvilinear and Radial Type Continuous Extrusion Machines becomes increasingly significant. These machines not only contribute to the optimization of manufacturing operations but also play a crucial role in advancing the capabilities of industries to produce high-quality, innovative products. The continuous evolution of extrusion technology is paving the way for new opportunities and applications, driving the growth and development of the Global Continuous Rotary Extrusion Equipment Market.

Copper, Aluminum, Cast Irons, Aluminum Bronzes, Oxygen-Free Coppe, Others in the Global Continuous Rotary Extrusion Equipment Market:

The Global Continuous Rotary Extrusion Equipment Market plays a vital role in the processing and production of various metals and alloys, including copper, aluminum, cast irons, aluminum bronzes, oxygen-free copper, and others. In the copper industry, continuous rotary extrusion equipment is used to produce high-quality copper wires, rods, and tubes, which are essential components in electrical and electronic applications. The precision and efficiency of these machines ensure that the copper products meet stringent quality standards, making them suitable for use in critical applications such as power transmission and telecommunications. Similarly, in the aluminum industry, continuous rotary extrusion equipment is employed to produce lightweight and durable aluminum profiles and components. These products are widely used in the automotive and aerospace sectors, where weight reduction and strength are crucial factors. The ability of continuous rotary extrusion machines to produce complex shapes and profiles with minimal waste makes them an ideal choice for aluminum processing. In the case of cast irons, continuous rotary extrusion equipment is used to produce components with excellent mechanical properties and wear resistance. These components are commonly used in the construction and heavy machinery industries, where durability and reliability are essential. Aluminum bronzes, known for their corrosion resistance and strength, are also processed using continuous rotary extrusion equipment. These alloys are used in marine and industrial applications, where exposure to harsh environments is a concern. Oxygen-free copper, valued for its high conductivity and purity, is another material that benefits from continuous rotary extrusion processes. The precision and control offered by these machines ensure that the oxygen-free copper products meet the highest standards of quality and performance. In addition to these materials, continuous rotary extrusion equipment is also used to process a wide range of other metals and alloys, catering to the diverse needs of various industries. The versatility and efficiency of these machines make them an indispensable tool in modern manufacturing, enabling industries to produce high-quality products that meet the demands of today's competitive market. As the Global Continuous Rotary Extrusion Equipment Market continues to evolve, it is expected to play an increasingly important role in the processing and production of advanced materials, driving innovation and growth across multiple sectors.

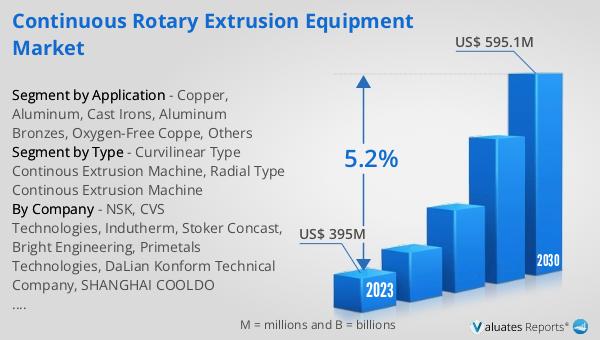

Global Continuous Rotary Extrusion Equipment Market Outlook:

The outlook for the Global Continuous Rotary Extrusion Equipment Market indicates a promising growth trajectory over the coming years. The market is anticipated to expand from a valuation of US$ 439 million in 2024 to approximately US$ 595.1 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 5.2% during the forecast period. This positive outlook is driven by several factors, including the increasing demand for advanced extrusion solutions across various industries such as automotive, aerospace, and construction. As these industries continue to seek innovative ways to enhance their production processes and meet evolving consumer demands, the need for efficient and high-performance extrusion equipment is becoming more pronounced. Additionally, technological advancements in extrusion machinery, coupled with a growing emphasis on energy efficiency and sustainability, are further contributing to the market's growth. Manufacturers are investing in research and development to enhance the capabilities and performance of continuous rotary extrusion equipment, enabling them to offer more sophisticated and versatile solutions to their customers. As a result, the Global Continuous Rotary Extrusion Equipment Market is poised to play a crucial role in shaping the future of manufacturing and material processing, providing industries with the tools they need to produce high-quality, innovative products.

| Report Metric | Details |

| Report Name | Continuous Rotary Extrusion Equipment Market |

| Accounted market size in 2024 | US$ 439 million |

| Forecasted market size in 2030 | US$ 595.1 million |

| CAGR | 5.2 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | NSK, CVS Technologies, Indutherm, Stoker Concast, Bright Engineering, Primetals Technologies, DaLian Konform Technical Company, SHANGHAI COOLDO INDUSTRIAL |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |