What is Three Phase Hybrid Battery Storage Inverter - Global Market?

The Three Phase Hybrid Battery Storage Inverter is a sophisticated technology that plays a crucial role in the global energy landscape. It combines the functionalities of a battery inverter and a solar inverter, allowing for seamless integration of renewable energy sources with traditional power grids. This technology is particularly significant in managing energy storage and distribution, ensuring that energy generated from renewable sources like solar and wind can be efficiently stored and used when needed. The global market for these inverters is driven by the increasing demand for sustainable energy solutions and the need to reduce carbon emissions. As countries worldwide strive to meet their carbon neutrality goals, the adoption of hybrid battery storage inverters is becoming more prevalent. These inverters are designed to handle three-phase power, which is commonly used in industrial and commercial settings, making them versatile and suitable for a wide range of applications. The market is characterized by continuous technological advancements, with manufacturers focusing on improving efficiency, reliability, and cost-effectiveness. As a result, the Three Phase Hybrid Battery Storage Inverter market is poised for significant growth, driven by the global shift towards renewable energy and the increasing emphasis on energy efficiency.

5-8KW, 8-12KW, Others in the Three Phase Hybrid Battery Storage Inverter - Global Market:

In the Three Phase Hybrid Battery Storage Inverter market, the power capacity segments of 5-8KW, 8-12KW, and others play a pivotal role in catering to diverse energy needs across various sectors. The 5-8KW segment is primarily targeted towards residential and small commercial applications. These inverters are ideal for homeowners looking to optimize their energy consumption by integrating solar power with battery storage. They offer a balanced solution for households with moderate energy demands, providing enough capacity to store solar energy for use during peak hours or power outages. The 8-12KW segment, on the other hand, is more suited for larger residential properties and medium-sized commercial establishments. These inverters offer higher power capacity, making them suitable for businesses that require a more robust energy solution to support their operations. They are particularly beneficial for commercial entities that aim to reduce their reliance on the grid and lower their energy costs. The "Others" category encompasses inverters with capacities beyond 12KW, which are typically used in large commercial and industrial settings. These high-capacity inverters are designed to handle substantial energy loads, making them ideal for factories, warehouses, and utility-scale projects. They provide the necessary power to support large-scale operations and are integral to the energy management strategies of businesses with significant energy consumption. Across all segments, the demand for Three Phase Hybrid Battery Storage Inverters is driven by the need for reliable and efficient energy solutions that can accommodate the growing use of renewable energy sources. As businesses and homeowners alike seek to reduce their carbon footprint and energy costs, the adoption of these inverters is expected to rise. Manufacturers are continuously innovating to enhance the performance and efficiency of these inverters, ensuring they meet the evolving needs of the market. The integration of advanced features such as remote monitoring, smart grid compatibility, and enhanced safety mechanisms further adds to their appeal. As the global energy landscape continues to evolve, the Three Phase Hybrid Battery Storage Inverter market is set to expand, offering a range of solutions to meet the diverse energy needs of consumers worldwide.

Residential, Commercial, Utility in the Three Phase Hybrid Battery Storage Inverter - Global Market:

The usage of Three Phase Hybrid Battery Storage Inverters spans across residential, commercial, and utility sectors, each with distinct requirements and benefits. In residential settings, these inverters are increasingly popular among homeowners who are keen on adopting renewable energy solutions. They enable households to harness solar energy efficiently, storing excess power generated during the day for use during nighttime or cloudy days. This not only reduces reliance on the grid but also helps in lowering electricity bills. Moreover, with the growing trend of smart homes, these inverters can be integrated with home energy management systems, allowing homeowners to monitor and optimize their energy usage in real-time. In the commercial sector, Three Phase Hybrid Battery Storage Inverters are essential for businesses looking to enhance their energy efficiency and sustainability. They provide a reliable energy solution that can support the operational needs of businesses, from small shops to large office buildings. By integrating these inverters, businesses can reduce their energy costs, improve their energy independence, and contribute to environmental sustainability. Additionally, they offer backup power solutions, ensuring business continuity during power outages. In the utility sector, these inverters play a critical role in supporting the integration of renewable energy into the grid. They help in balancing energy supply and demand, ensuring grid stability and reliability. Utility companies use these inverters to manage large-scale energy storage systems, which are crucial for accommodating the intermittent nature of renewable energy sources like wind and solar. By storing excess energy during periods of low demand and releasing it during peak times, these inverters help in optimizing the overall energy distribution and reducing the need for fossil fuel-based power generation. As the world moves towards a more sustainable energy future, the role of Three Phase Hybrid Battery Storage Inverters in these sectors is set to become increasingly important.

Three Phase Hybrid Battery Storage Inverter - Global Market Outlook:

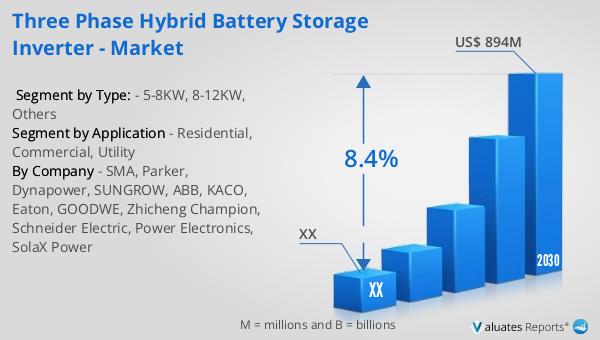

The global market for Three Phase Hybrid Battery Storage Inverters was valued at approximately US$ 489 million in 2023. It is projected to grow to a revised size of US$ 894 million by 2030, reflecting a compound annual growth rate (CAGR) of 8.4% during the forecast period from 2024 to 2030. This growth is largely attributed to the rapid advancements in the wind power and photovoltaic industries, coupled with the rising awareness of environmental protection across various countries. As nations strive to achieve their carbon neutrality targets, the energy storage industry has emerged as a key technology in facilitating this transition. The increasing adoption of renewable energy sources necessitates efficient energy storage solutions, and Three Phase Hybrid Battery Storage Inverters are at the forefront of this technological evolution. They offer a versatile and efficient means of integrating renewable energy into existing power grids, thereby supporting the global shift towards sustainable energy. The market's expansion is further driven by government initiatives and policies aimed at promoting clean energy and reducing carbon emissions. As a result, the demand for these inverters is expected to rise significantly, making them an integral component of the global energy landscape.

| Report Metric | Details |

| Report Name | Three Phase Hybrid Battery Storage Inverter - Market |

| Forecasted market size in 2030 | US$ 894 million |

| CAGR | 8.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | SMA, Parker, Dynapower, SUNGROW, ABB, KACO, Eaton, GOODWE, Zhicheng Champion, Schneider Electric, Power Electronics, SolaX Power |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |