What is Electrical-Electronic (E-E) Architectures - Global Market?

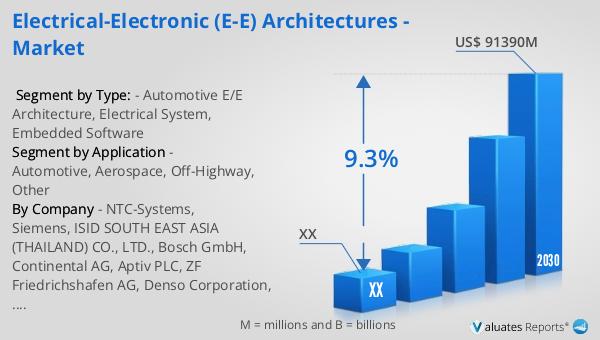

Electrical-Electronic (E-E) Architectures refer to the complex systems that integrate electrical and electronic components within various industries, primarily focusing on automotive, aerospace, and other sectors. These architectures are essential for managing the electrical distribution and electronic control systems that power modern vehicles and machinery. The global market for E-E architectures is driven by the increasing demand for advanced technologies that enhance performance, safety, and efficiency. As industries continue to innovate, the need for sophisticated E-E architectures grows, enabling the integration of features such as autonomous driving, connectivity, and electrification. This market is characterized by rapid technological advancements and a shift towards more sustainable and efficient systems. The global market for Electrical-Electronic (E-E) Architectures was estimated to be worth US$ 40,330 million in 2023 and is forecast to reach a readjusted size of US$ 91,390 million by 2030, with a compound annual growth rate (CAGR) of 9.3% during the forecast period from 2024 to 2030. This growth is indicative of the increasing reliance on electronic systems across various sectors, highlighting the importance of E-E architectures in shaping the future of technology and industry.

Automotive E/E Architecture, Electrical System, Embedded Software in the Electrical-Electronic (E-E) Architectures - Global Market:

Automotive E/E Architecture is a critical component of modern vehicles, encompassing the electrical systems and embedded software that enable various functionalities. These architectures are designed to manage the complex network of electronic control units (ECUs) that govern everything from engine performance to infotainment systems. The electrical system within an automotive E/E architecture includes wiring harnesses, connectors, and power distribution components that ensure the seamless operation of electronic devices. Embedded software plays a crucial role in this architecture, providing the necessary instructions for ECUs to perform specific tasks. As vehicles become more advanced, the complexity of E/E architectures increases, requiring sophisticated software solutions to manage the growing number of electronic components. The global market for automotive E/E architectures is driven by the demand for features such as autonomous driving, connectivity, and electrification. These trends necessitate the development of more efficient and reliable electrical systems that can support the increased data processing and communication requirements. Additionally, the push towards sustainability and reduced emissions has led to the integration of electric and hybrid powertrains, further complicating the E/E architecture. As a result, manufacturers are investing in advanced technologies and innovative solutions to meet the evolving needs of the automotive industry. The electrical system within an automotive E/E architecture is responsible for distributing power to various components, ensuring that each device receives the necessary voltage and current to function properly. This system includes wiring harnesses, connectors, and power distribution units that facilitate the flow of electricity throughout the vehicle. As vehicles become more complex, the demand for efficient and reliable electrical systems increases, driving innovation in this area. Embedded software is a key component of automotive E/E architectures, providing the necessary instructions for electronic control units (ECUs) to perform specific tasks. This software is responsible for managing the communication between different ECUs, ensuring that each unit receives the necessary data to function properly. As vehicles become more advanced, the complexity of embedded software increases, requiring sophisticated solutions to manage the growing number of electronic components. The global market for automotive E/E architectures is driven by the demand for features such as autonomous driving, connectivity, and electrification. These trends necessitate the development of more efficient and reliable electrical systems that can support the increased data processing and communication requirements. Additionally, the push towards sustainability and reduced emissions has led to the integration of electric and hybrid powertrains, further complicating the E/E architecture. As a result, manufacturers are investing in advanced technologies and innovative solutions to meet the evolving needs of the automotive industry.

Automotive, Aerospace, Off-Highway, Other in the Electrical-Electronic (E-E) Architectures - Global Market:

The usage of Electrical-Electronic (E-E) Architectures extends across various industries, including automotive, aerospace, off-highway, and others, each with unique requirements and applications. In the automotive sector, E-E architectures are crucial for integrating advanced technologies such as autonomous driving, connectivity, and electrification. These architectures manage the complex network of electronic control units (ECUs) that govern everything from engine performance to infotainment systems. As vehicles become more advanced, the complexity of E-E architectures increases, requiring sophisticated software solutions to manage the growing number of electronic components. In the aerospace industry, E-E architectures play a vital role in ensuring the safety and efficiency of aircraft systems. These architectures manage the electrical distribution and electronic control systems that power various components, including navigation, communication, and flight control systems. The demand for more efficient and reliable E-E architectures in aerospace is driven by the need for enhanced safety, performance, and fuel efficiency. In the off-highway sector, E-E architectures are essential for managing the electrical and electronic systems of heavy machinery and equipment. These architectures ensure the seamless operation of components such as engines, transmissions, and hydraulic systems, enabling efficient and reliable performance in demanding environments. The global market for E-E architectures in the off-highway sector is driven by the increasing demand for advanced technologies that enhance productivity and reduce emissions. Other industries, such as industrial automation and consumer electronics, also rely on E-E architectures to manage the complex network of electronic components that power various devices and systems. The global market for E-E architectures is characterized by rapid technological advancements and a shift towards more sustainable and efficient systems. As industries continue to innovate, the need for sophisticated E-E architectures grows, enabling the integration of features such as connectivity, automation, and electrification. This growth is indicative of the increasing reliance on electronic systems across various sectors, highlighting the importance of E-E architectures in shaping the future of technology and industry.

Electrical-Electronic (E-E) Architectures - Global Market Outlook:

The global market for Electrical-Electronic (E-E) Architectures was valued at approximately US$ 40,330 million in 2023, with projections indicating a significant increase to US$ 91,390 million by 2030. This growth represents a compound annual growth rate (CAGR) of 9.3% during the forecast period from 2024 to 2030. The North American market for E-E architectures is also expected to experience substantial growth, although specific figures for this region were not provided. The increasing demand for advanced technologies that enhance performance, safety, and efficiency is driving the growth of the E-E architectures market globally. As industries continue to innovate, the need for sophisticated E-E architectures grows, enabling the integration of features such as autonomous driving, connectivity, and electrification. This market is characterized by rapid technological advancements and a shift towards more sustainable and efficient systems. The growth of the E-E architectures market is indicative of the increasing reliance on electronic systems across various sectors, highlighting the importance of E-E architectures in shaping the future of technology and industry. As the market continues to expand, manufacturers are investing in advanced technologies and innovative solutions to meet the evolving needs of various industries.

| Report Metric | Details |

| Report Name | Electrical-Electronic (E-E) Architectures - Market |

| Forecasted market size in 2030 | US$ 91390 million |

| CAGR | 9.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | NTC-Systems, Siemens, ISID SOUTH EAST ASIA (THAILAND) CO., LTD., Bosch GmbH, Continental AG, Aptiv PLC, ZF Friedrichshafen AG, Denso Corporation, Veoneer Inc., Magna International Inc., Lear Corporation, Hyundai Mobis Co., Ltd., Harman International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |