What is Surgical Anti-Adhesion Material - Global Market?

Surgical anti-adhesion materials are specialized medical products designed to prevent the formation of adhesions, which are bands of scar tissue that can form between tissues and organs following surgery. These adhesions can lead to complications such as chronic pain, bowel obstruction, and infertility, making their prevention crucial in post-operative care. The global market for surgical anti-adhesion materials is driven by the increasing number of surgical procedures worldwide, advancements in medical technology, and a growing awareness of post-surgical complications. These materials are typically used in various types of surgeries, including abdominal, gynecological, and orthopedic procedures. They come in different forms, such as films, gels, and liquids, each designed to create a physical barrier between tissues to reduce the risk of adhesion formation. The market is characterized by continuous research and development efforts aimed at improving the efficacy and safety of these materials, as well as expanding their applications. As healthcare systems globally strive to improve surgical outcomes and patient quality of life, the demand for effective anti-adhesion solutions is expected to grow, making this a dynamic and evolving sector within the broader medical device industry.

Chitosan, Sodium Hyaluronate, Polylactic Acid in the Surgical Anti-Adhesion Material - Global Market:

Chitosan, sodium hyaluronate, and polylactic acid are three prominent materials used in the development of surgical anti-adhesion products, each offering unique properties that contribute to their effectiveness in preventing post-surgical adhesions. Chitosan, a natural polysaccharide derived from the shells of crustaceans, is valued for its biocompatibility, biodegradability, and ability to promote wound healing. In the context of surgical anti-adhesion, chitosan-based products are often used in the form of films or gels that can be applied directly to surgical sites. These products work by forming a protective barrier that prevents tissues from sticking together during the healing process. Additionally, chitosan's inherent antimicrobial properties can help reduce the risk of post-operative infections, further enhancing its appeal in surgical applications. Sodium hyaluronate, a salt form of hyaluronic acid, is another widely used material in anti-adhesion products. Known for its excellent biocompatibility and viscoelastic properties, sodium hyaluronate is often used in gel form to create a temporary physical barrier between tissues. Its ability to retain moisture and provide lubrication makes it particularly effective in reducing friction and preventing adhesion formation. Moreover, sodium hyaluronate is naturally present in the human body, which minimizes the risk of adverse reactions and enhances its acceptance in medical applications. Polylactic acid (PLA), a biodegradable polymer derived from renewable resources like corn starch or sugarcane, is also utilized in the production of anti-adhesion materials. PLA-based products are typically available as films or meshes that can be placed over surgical sites to prevent tissue adhesion. The biodegradability of PLA ensures that these products gradually break down in the body, eliminating the need for surgical removal. Furthermore, PLA's mechanical properties can be tailored to suit specific surgical requirements, making it a versatile option for various types of procedures. The use of these materials in surgical anti-adhesion products reflects a broader trend towards biocompatible and sustainable solutions in the medical field. As research continues to advance, there is potential for the development of new formulations and combinations of these materials to enhance their effectiveness and expand their applications. This ongoing innovation is crucial in addressing the diverse needs of patients and healthcare providers, ultimately contributing to improved surgical outcomes and quality of life.

Abdominal Surgery, Gynecological Surgery, Others in the Surgical Anti-Adhesion Material - Global Market:

Surgical anti-adhesion materials play a vital role in various surgical procedures, particularly in abdominal and gynecological surgeries, where the risk of adhesion formation is notably high. In abdominal surgery, adhesions can lead to serious complications such as bowel obstruction, chronic abdominal pain, and difficulties in future surgeries. Anti-adhesion materials are used to create a barrier between tissues and organs, reducing the likelihood of these complications. For instance, during procedures like appendectomies or colorectal surgeries, surgeons may apply anti-adhesion films or gels to the surgical site to prevent the intestines from adhering to the abdominal wall or other organs. This not only helps in minimizing post-operative complications but also aids in faster recovery and improved patient outcomes. In gynecological surgery, adhesions can cause infertility, pelvic pain, and complications in subsequent surgeries. Anti-adhesion materials are particularly beneficial in procedures such as hysterectomies, myomectomies, and endometriosis surgeries. By preventing the formation of scar tissue between reproductive organs, these materials help preserve fertility and reduce the risk of chronic pelvic pain. The use of anti-adhesion products in gynecological surgeries is crucial for maintaining reproductive health and enhancing the quality of life for patients. Beyond abdominal and gynecological surgeries, anti-adhesion materials are also used in other surgical fields, including orthopedic, cardiovascular, and neurological surgeries. In orthopedic procedures, for example, these materials can prevent adhesions around tendons and joints, facilitating better mobility and reducing post-operative pain. In cardiovascular surgeries, anti-adhesion barriers can help prevent the formation of scar tissue around the heart or blood vessels, which can impede normal function. Similarly, in neurological surgeries, these materials can reduce the risk of adhesions forming around the brain or spinal cord, which can lead to serious complications. The versatility of surgical anti-adhesion materials in various medical fields underscores their importance in modern surgical practice. As surgical techniques continue to evolve and the demand for minimally invasive procedures increases, the development and application of effective anti-adhesion solutions will remain a critical focus for healthcare providers and researchers alike.

Surgical Anti-Adhesion Material - Global Market Outlook:

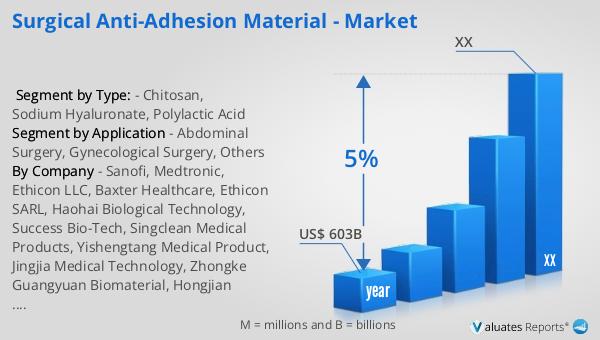

Based on our comprehensive analysis, the global market for medical devices, which includes surgical anti-adhesion materials, is projected to reach approximately USD 603 billion in 2023. This expansive market is anticipated to experience a steady growth trajectory, with a compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by several factors, including the increasing prevalence of chronic diseases, an aging global population, and advancements in medical technology. As healthcare systems worldwide strive to improve patient outcomes and reduce healthcare costs, the demand for innovative medical devices, including surgical anti-adhesion materials, is expected to rise. These materials play a crucial role in enhancing surgical outcomes by preventing post-operative complications, thereby improving patient quality of life and reducing the need for additional medical interventions. The market's growth is also supported by ongoing research and development efforts aimed at improving the efficacy and safety of these materials, as well as expanding their applications across various surgical fields. As a result, the surgical anti-adhesion material market is poised for significant growth, driven by the increasing demand for effective solutions to prevent post-surgical adhesions and improve patient outcomes.

| Report Metric | Details |

| Report Name | Surgical Anti-Adhesion Material - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Sanofi, Medtronic, Ethicon LLC, Baxter Healthcare, Ethicon SARL, Haohai Biological Technology, Success Bio-Tech, Singclean Medical Products, Yishengtang Medical Product, Jingjia Medical Technology, Zhongke Guangyuan Biomaterial, Hongjian Biomedical Products, Ruinuo Medical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |