What is Medical Polyisoprene Gasket - Global Market?

Medical polyisoprene gaskets are essential components in the healthcare industry, particularly in the manufacturing of medical devices. These gaskets are made from synthetic rubber, known for its excellent elasticity, resilience, and biocompatibility, making it ideal for medical applications. The global market for medical polyisoprene gaskets is driven by the increasing demand for medical devices that require reliable sealing solutions. These gaskets are used in various medical equipment to ensure airtight and leak-proof seals, which are crucial for maintaining sterility and preventing contamination. The market is also influenced by advancements in medical technology and the growing emphasis on patient safety. As healthcare standards continue to rise globally, the need for high-quality gaskets that meet stringent regulatory requirements is becoming more pronounced. Manufacturers are focusing on developing innovative gasket solutions that offer superior performance and durability, catering to the diverse needs of the medical industry. The global market for medical polyisoprene gaskets is poised for growth as healthcare providers and medical device manufacturers seek reliable and efficient sealing solutions to enhance the safety and efficacy of medical devices.

20PP, 25PP, 30PP in the Medical Polyisoprene Gasket - Global Market:

In the context of the medical polyisoprene gasket global market, the terms 20PP, 25PP, and 30PP refer to specific grades or formulations of polyisoprene used in gasket manufacturing. These grades are distinguished by their unique properties, which make them suitable for different applications within the medical field. The "PP" in these terms stands for "polyisoprene polymer," and the numbers indicate the specific formulation or blend of the polymer. Each grade offers distinct characteristics in terms of elasticity, tensile strength, and resistance to various environmental factors. For instance, 20PP might be a softer formulation, offering greater flexibility and elasticity, making it ideal for applications where a tight seal is required without exerting excessive pressure on the surrounding components. This grade could be particularly useful in delicate medical devices where precision and gentle sealing are paramount. On the other hand, 25PP might offer a balance between flexibility and strength, providing a robust seal while maintaining some degree of elasticity. This makes it suitable for a wider range of applications, including those that require moderate pressure resistance and durability. It could be used in devices that experience varying pressure levels or require a reliable seal over extended periods. Meanwhile, 30PP might be a more rigid formulation, offering enhanced strength and resistance to environmental factors such as temperature fluctuations and chemical exposure. This grade would be ideal for applications where the gasket needs to withstand harsh conditions or provide a long-lasting seal in demanding environments. It could be used in medical devices that are exposed to sterilization processes or require a high degree of chemical resistance. The choice between these grades depends on the specific requirements of the medical device and the conditions it will be exposed to. Manufacturers must carefully consider factors such as the intended use of the device, the environmental conditions it will encounter, and the regulatory standards it must meet. By selecting the appropriate grade of polyisoprene, manufacturers can ensure that their gaskets provide optimal performance and reliability, contributing to the overall safety and efficacy of the medical device. As the global market for medical polyisoprene gaskets continues to evolve, the demand for these specialized grades is expected to grow, driven by the increasing complexity and diversity of medical devices. Manufacturers are likely to invest in research and development to create new formulations that offer even greater performance and versatility, catering to the ever-changing needs of the healthcare industry.

Infusion Bags, Infusion Bottle in the Medical Polyisoprene Gasket - Global Market:

Medical polyisoprene gaskets play a crucial role in the functionality and safety of infusion bags and infusion bottles, which are widely used in healthcare settings for the administration of fluids and medications. These gaskets ensure that the containers are sealed effectively, preventing leaks and maintaining the sterility of the contents. In infusion bags, polyisoprene gaskets are used to create a secure seal around the ports where the infusion set is connected. This is vital to prevent any contamination from entering the bag and to ensure that the fluid is delivered safely to the patient. The elasticity and resilience of polyisoprene make it an ideal material for this application, as it can accommodate the movement and pressure changes that occur during the infusion process without compromising the integrity of the seal. Similarly, in infusion bottles, polyisoprene gaskets are used to seal the bottle cap, ensuring that the contents remain sterile and uncontaminated until they are administered to the patient. The gasket must provide a reliable seal that can withstand the rigors of transportation and storage, as well as the pressure changes that occur when the bottle is opened and the fluid is dispensed. The use of polyisoprene in these applications is driven by its excellent biocompatibility, which ensures that it does not react with the contents of the infusion bag or bottle, nor does it cause any adverse reactions in patients. Additionally, polyisoprene gaskets are designed to meet stringent regulatory standards, ensuring that they are safe and effective for use in medical applications. The global market for medical polyisoprene gaskets in infusion bags and bottles is expected to grow as the demand for safe and reliable infusion solutions increases. Healthcare providers are increasingly looking for products that offer superior performance and safety, and polyisoprene gaskets are well-positioned to meet these needs. Manufacturers are likely to continue investing in research and development to enhance the properties of polyisoprene gaskets, ensuring that they remain at the forefront of innovation in the medical device industry. As the healthcare landscape continues to evolve, the importance of high-quality sealing solutions in infusion bags and bottles will only become more pronounced, driving further growth in the global market for medical polyisoprene gaskets.

Medical Polyisoprene Gasket - Global Market Outlook:

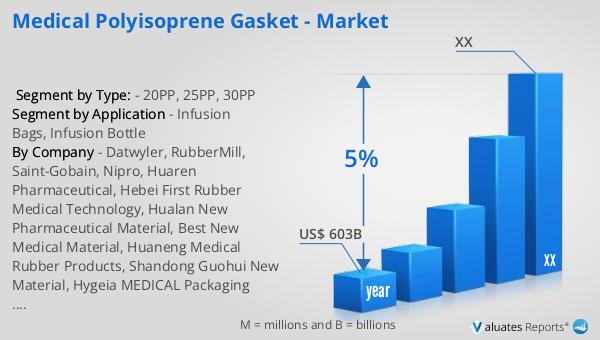

Based on our comprehensive analysis, the global market for medical devices is projected to reach approximately USD 603 billion in 2023. This substantial market size reflects the growing demand for medical devices across various healthcare sectors. Over the next six years, the market is anticipated to expand at a compound annual growth rate (CAGR) of 5%. This growth trajectory underscores the increasing reliance on advanced medical technologies and devices to improve patient outcomes and streamline healthcare delivery. The steady growth rate also highlights the continuous innovation and development within the medical device industry, as manufacturers strive to meet the evolving needs of healthcare providers and patients. Factors contributing to this growth include the rising prevalence of chronic diseases, an aging global population, and the increasing adoption of minimally invasive surgical procedures. Additionally, advancements in medical technology, such as the integration of artificial intelligence and the Internet of Things (IoT) in medical devices, are expected to drive further market expansion. As the global healthcare landscape continues to evolve, the demand for innovative and effective medical devices will remain a key driver of market growth. The projected growth rate of 5% over the next six years indicates a robust and dynamic market environment, offering significant opportunities for manufacturers and stakeholders in the medical device industry.

| Report Metric | Details |

| Report Name | Medical Polyisoprene Gasket - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Datwyler, RubberMill, Saint-Gobain, Nipro, Huaren Pharmaceutical, Hebei First Rubber Medical Technology, Hualan New Pharmaceutical Material, Best New Medical Material, Huaneng Medical Rubber Products, Shandong Guohui New Material, Hygeia MEDICAL Packaging Technology, Shijiazhuang NO.4 Pharmaceutical, Tejie Rubber&Plastic, Jintai Industry, Hebei Yaofeng Medicine Packing Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |