What is Global Laminated Steel for Food and Beverages Market?

The global Laminated Steel for Food and Beverages market is a specialized segment within the broader steel industry, focusing on the production and application of laminated steel materials specifically designed for packaging food and beverages. Laminated steel is a composite material that combines the strength and durability of steel with the protective and aesthetic benefits of a laminated coating. This type of steel is particularly valuable in the food and beverage industry due to its ability to provide superior barrier properties against moisture, oxygen, and other contaminants, thereby extending the shelf life of products. Additionally, laminated steel offers excellent printability, allowing for high-quality branding and labeling, which is crucial for market differentiation. The market for laminated steel in this sector is driven by increasing consumer demand for packaged food and beverages, advancements in packaging technology, and stringent regulatory standards aimed at ensuring food safety and quality. As a result, manufacturers are continually innovating to develop more efficient and sustainable laminated steel solutions to meet these evolving needs.

Fusion Method Laminated Steel, Bonding Agent Laminated Steel in the Global Laminated Steel for Food and Beverages Market:

Fusion Method Laminated Steel and Bonding Agent Laminated Steel are two prominent types of laminated steel used in the global food and beverages market. Fusion Method Laminated Steel involves the direct bonding of a polymer film to the steel substrate through a heat and pressure process. This method ensures a strong, uniform adhesion between the layers, resulting in a highly durable and corrosion-resistant material. The fusion method is particularly advantageous for applications requiring high mechanical strength and resistance to harsh environmental conditions, such as canned foods and beverages. On the other hand, Bonding Agent Laminated Steel utilizes an adhesive layer to bond the polymer film to the steel substrate. This method allows for greater flexibility in the choice of polymer films and adhesives, enabling manufacturers to tailor the properties of the laminated steel to specific application requirements. Bonding agent laminated steel is often used in applications where specific barrier properties, such as resistance to certain chemicals or enhanced printability, are critical. Both types of laminated steel offer significant benefits in terms of product protection, shelf life extension, and aesthetic appeal, making them essential materials in the food and beverage packaging industry. The choice between fusion method and bonding agent laminated steel depends on various factors, including the intended application, required performance characteristics, and cost considerations. As the demand for high-quality, sustainable packaging solutions continues to grow, manufacturers are investing in research and development to enhance the performance and versatility of laminated steel products. This ongoing innovation is expected to drive the adoption of both fusion method and bonding agent laminated steel in the global food and beverages market.

Food, Beverages in the Global Laminated Steel for Food and Beverages Market:

The usage of laminated steel in the global food and beverages market spans a wide range of applications, each leveraging the unique properties of this material to enhance product quality and consumer appeal. In the food sector, laminated steel is commonly used for packaging canned goods, such as vegetables, fruits, soups, and ready-to-eat meals. The material's excellent barrier properties protect the contents from moisture, oxygen, and light, thereby preserving the nutritional value, flavor, and texture of the food. Additionally, laminated steel cans are highly durable and resistant to physical damage, ensuring that the packaged food remains safe and intact during transportation and storage. The ability to print high-quality graphics on laminated steel also allows manufacturers to create visually appealing packaging that attracts consumers and communicates important product information. In the beverages sector, laminated steel is widely used for packaging a variety of drinks, including carbonated beverages, juices, and alcoholic beverages. The material's strength and resistance to corrosion make it ideal for containing pressurized liquids, while its barrier properties help maintain the freshness and flavor of the beverages. Laminated steel cans are also lightweight and easy to stack, making them convenient for both manufacturers and consumers. Furthermore, the recyclability of laminated steel aligns with the growing consumer demand for sustainable packaging solutions. Overall, the use of laminated steel in the food and beverages market offers numerous benefits, including enhanced product protection, extended shelf life, and improved branding opportunities, making it a valuable material for manufacturers looking to meet the evolving needs of consumers.

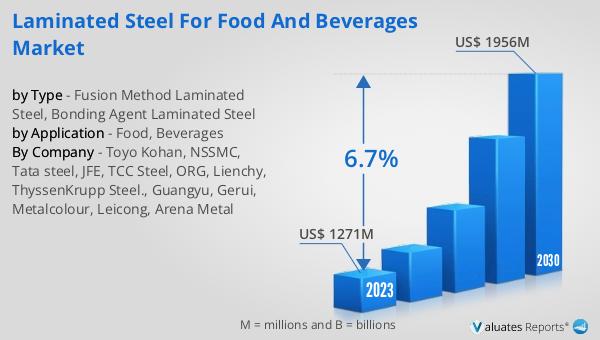

Global Laminated Steel for Food and Beverages Market Outlook:

The global Laminated Steel for Food and Beverages market was valued at US$ 1271 million in 2023 and is anticipated to reach US$ 1956 million by 2030, witnessing a CAGR of 6.7% during the forecast period 2024-2030. This significant growth reflects the increasing demand for high-quality, durable, and sustainable packaging solutions in the food and beverage industry. Laminated steel, with its superior barrier properties, durability, and printability, is becoming an essential material for manufacturers aiming to enhance product protection and consumer appeal. The market's expansion is driven by several factors, including advancements in packaging technology, rising consumer demand for packaged food and beverages, and stringent regulatory standards focused on food safety and quality. As manufacturers continue to innovate and develop more efficient laminated steel solutions, the market is expected to experience sustained growth, offering numerous opportunities for industry players to capitalize on the evolving needs of the food and beverage sector.

| Report Metric | Details |

| Report Name | Laminated Steel for Food and Beverages Market |

| Accounted market size in 2023 | US$ 1271 million |

| Forecasted market size in 2030 | US$ 1956 million |

| CAGR | 6.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toyo Kohan, NSSMC, Tata steel, JFE, TCC Steel, ORG, Lienchy, ThyssenKrupp Steel., Guangyu, Gerui, Metalcolour, Leicong, Arena Metal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |