What is Global Titanium Medical Component Market?

The Global Titanium Medical Component Market is a specialized segment within the broader medical device industry, focusing on the use of titanium and its alloys in various medical applications. Titanium is highly valued in the medical field due to its exceptional properties, such as biocompatibility, corrosion resistance, and high strength-to-weight ratio. These characteristics make it an ideal material for manufacturing medical components that need to be both durable and safe for long-term implantation in the human body. The market encompasses a wide range of products, including surgical instruments, implants, and other medical devices that require high precision and reliability. The demand for titanium medical components is driven by the increasing prevalence of chronic diseases, advancements in medical technology, and the growing aging population, which collectively contribute to the need for more sophisticated and durable medical solutions. As healthcare systems worldwide continue to evolve, the Global Titanium Medical Component Market is expected to play a crucial role in enhancing patient outcomes and improving the overall quality of medical care.

Alloy Titanium, Non-alloyed Titanium in the Global Titanium Medical Component Market:

Alloy titanium and non-alloyed titanium are two primary categories within the Global Titanium Medical Component Market, each offering unique benefits and applications. Alloy titanium, also known as titanium alloy, is a mixture of titanium with other metals such as aluminum, vanadium, and nickel. This combination enhances the mechanical properties of titanium, making it even stronger and more resistant to wear and tear. Titanium alloys are commonly used in applications that require high strength and durability, such as orthopedic implants, dental implants, and surgical instruments. The addition of other metals allows for the customization of the alloy's properties to meet specific medical requirements, such as increased flexibility or enhanced resistance to fatigue. On the other hand, non-alloyed titanium, also known as commercially pure titanium, is composed of 99% or more titanium. It is highly biocompatible and exhibits excellent corrosion resistance, making it suitable for applications where direct contact with bodily tissues and fluids is required. Non-alloyed titanium is often used in the production of prosthetic devices, cardiovascular implants, and other medical components that need to be both lightweight and strong. The choice between alloy and non-alloyed titanium depends on the specific needs of the medical application, with each type offering distinct advantages. For instance, alloy titanium may be preferred for load-bearing implants due to its superior strength, while non-alloyed titanium might be chosen for applications where biocompatibility is the primary concern. Both types of titanium play a vital role in the Global Titanium Medical Component Market, contributing to the development of advanced medical devices that improve patient care and outcomes.

Medical Device, Prosthesis, Auxiliary Therapy Equipment in the Global Titanium Medical Component Market:

The Global Titanium Medical Component Market finds extensive usage in various medical areas, including medical devices, prostheses, and auxiliary therapy equipment. In the realm of medical devices, titanium is used to manufacture a wide range of products such as surgical instruments, dental implants, and cardiovascular devices. Its high strength-to-weight ratio and biocompatibility make it an ideal material for devices that need to be both durable and safe for long-term use. For example, titanium surgical instruments are known for their precision and reliability, which are crucial for successful surgical outcomes. In the field of prostheses, titanium is widely used to create artificial limbs and joints. Its lightweight nature and high strength make it an excellent choice for prosthetic components that need to withstand the stresses of daily use while providing comfort to the wearer. Titanium prostheses are also highly customizable, allowing for tailored solutions that meet the specific needs of individual patients. Additionally, titanium's biocompatibility ensures that it integrates well with the body's tissues, reducing the risk of rejection and complications. Auxiliary therapy equipment, such as external fixators and rehabilitation devices, also benefit from the use of titanium. These devices often require materials that are both strong and lightweight to ensure patient comfort and ease of use. Titanium's corrosion resistance further enhances its suitability for these applications, as it ensures the longevity and reliability of the equipment. Overall, the use of titanium in medical devices, prostheses, and auxiliary therapy equipment highlights its versatility and importance in the medical field. The Global Titanium Medical Component Market continues to grow as advancements in medical technology drive the demand for high-quality, durable, and biocompatible materials.

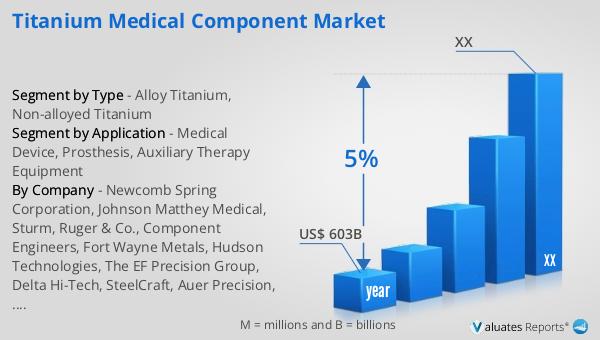

Global Titanium Medical Component Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by several factors, including the increasing prevalence of chronic diseases, advancements in medical technology, and the aging global population. As healthcare systems around the world continue to evolve, the demand for innovative and reliable medical devices is expected to rise. The Global Titanium Medical Component Market, being a crucial segment within the broader medical device industry, is poised to benefit from these trends. Titanium's unique properties, such as biocompatibility, corrosion resistance, and high strength-to-weight ratio, make it an ideal material for a wide range of medical applications. From surgical instruments and implants to prosthetic devices and auxiliary therapy equipment, titanium plays a vital role in enhancing patient outcomes and improving the overall quality of medical care. As the market continues to expand, the importance of titanium in the development of advanced medical solutions will only grow, further solidifying its position as a key material in the medical device industry.

| Report Metric | Details |

| Report Name | Titanium Medical Component Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Newcomb Spring Corporation, Johnson Matthey Medical, Sturm, Ruger & Co., Component Engineers, Fort Wayne Metals, Hudson Technologies, The EF Precision Group, Delta Hi-Tech, SteelCraft, Auer Precision, Cable Manufacturing & Assembly, Omni Components, Aerospace Alloys, Aerotronics, Foranne Manufacturing, JWP Manufacturing, Mendell, Fotofab, Motion Dynamics Corporation, Axian Technology, Astro Medical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |