What is Global 3D Laser Profile Measuring Instrument Market?

The Global 3D Laser Profile Measuring Instrument Market is a rapidly evolving sector that focuses on the development and deployment of advanced laser-based measurement tools. These instruments are designed to capture precise 3D profiles of objects, surfaces, and environments. They utilize laser technology to scan and measure the dimensions, shapes, and contours of various items with high accuracy. This market is driven by the increasing demand for precision in manufacturing, quality control, and inspection processes across various industries. The instruments are widely used in sectors such as automotive, consumer electronics, and semiconductors, where exact measurements are crucial for ensuring product quality and performance. The global market for these instruments is expanding as industries continue to adopt advanced technologies to enhance their production capabilities and maintain competitive advantages. The integration of 3D laser profile measuring instruments into manufacturing processes helps in reducing errors, improving efficiency, and ensuring compliance with stringent quality standards. As a result, the market is witnessing significant growth and innovation, with companies investing in research and development to introduce more sophisticated and user-friendly instruments.

640 Point, 1280 Point, 2048 Point, 3840 Point in the Global 3D Laser Profile Measuring Instrument Market:

In the Global 3D Laser Profile Measuring Instrument Market, the terms 640 Point, 1280 Point, 2048 Point, and 3840 Point refer to the resolution or the number of data points that the instrument can capture in a single scan. A 640 Point instrument captures 640 data points, providing a basic level of detail suitable for less complex applications. These instruments are often used in scenarios where high precision is not critical but where a general profile measurement is sufficient. Moving up, the 1280 Point instruments offer a higher resolution, capturing 1280 data points per scan. This increased resolution allows for more detailed measurements, making these instruments suitable for applications requiring moderate precision. The 2048 Point instruments take it a step further by capturing 2048 data points, offering even greater detail and accuracy. These are ideal for more complex applications where precise measurements are crucial, such as in the semiconductor industry or high-end consumer electronics manufacturing. Finally, the 3840 Point instruments represent the highest resolution available, capturing 3840 data points per scan. These instruments provide the most detailed and accurate measurements, making them indispensable in industries where the highest level of precision is required, such as in advanced automotive manufacturing and critical aerospace applications. The choice of instrument resolution depends on the specific needs of the application, with higher resolution instruments being more suitable for tasks that demand greater accuracy and detail. As technology advances, the market is seeing a trend towards higher resolution instruments, driven by the increasing demand for precision and the need to meet stringent quality standards in various industries.

Automotive Industry, Consumer Electronic, Semiconductor Industry, Others in the Global 3D Laser Profile Measuring Instrument Market:

The usage of Global 3D Laser Profile Measuring Instruments spans across several key industries, each benefiting from the precision and efficiency these tools offer. In the automotive industry, these instruments are used extensively for quality control and inspection processes. They help in measuring the dimensions and shapes of automotive components, ensuring that they meet the required specifications and tolerances. This is crucial for maintaining the safety and performance of vehicles. In the consumer electronics sector, 3D laser profile measuring instruments are used to inspect and measure the intricate components of devices such as smartphones, tablets, and laptops. The high precision of these instruments ensures that the components fit together perfectly, enhancing the overall quality and reliability of the products. In the semiconductor industry, these instruments play a vital role in the manufacturing process. They are used to measure the dimensions of semiconductor wafers and components with extreme accuracy, ensuring that they meet the stringent quality standards required in this industry. This helps in reducing defects and improving the performance of semiconductor devices. Apart from these industries, 3D laser profile measuring instruments are also used in various other sectors such as aerospace, medical devices, and construction. In aerospace, they are used to measure the dimensions and shapes of aircraft components, ensuring that they meet the required specifications for safety and performance. In the medical devices industry, these instruments are used to measure the dimensions of components such as implants and surgical instruments, ensuring that they meet the required standards for safety and efficacy. In the construction industry, they are used to measure the dimensions and shapes of structures, ensuring that they meet the required specifications for stability and safety. Overall, the usage of 3D laser profile measuring instruments is widespread across various industries, driven by the need for precision and efficiency in manufacturing and quality control processes.

Global 3D Laser Profile Measuring Instrument Market Outlook:

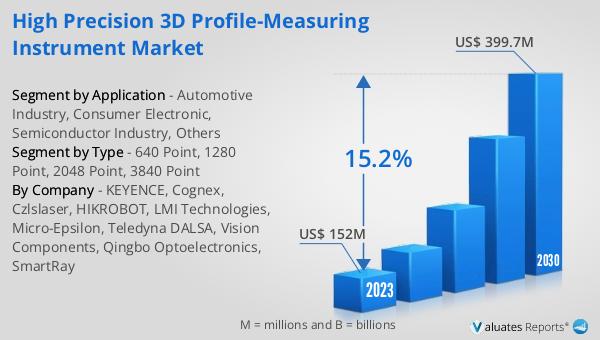

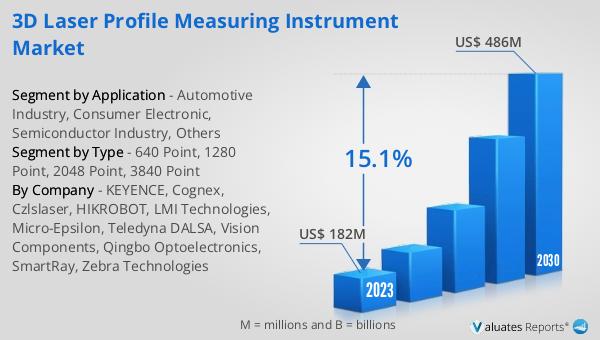

The global market for 3D Laser Profile Measuring Instruments was valued at $182 million in 2023 and is projected to grow significantly, reaching $486 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 15.1% during the forecast period from 2024 to 2030. This substantial increase in market value highlights the growing importance and adoption of these instruments across various industries. The rising demand for precision in manufacturing and quality control processes is a key driver of this market growth. As industries continue to adopt advanced technologies to enhance their production capabilities and maintain competitive advantages, the demand for high-precision measurement tools like 3D laser profile measuring instruments is expected to rise. The market is also witnessing significant innovation, with companies investing in research and development to introduce more sophisticated and user-friendly instruments. This trend is likely to continue, further driving the growth of the market. The increasing adoption of these instruments in industries such as automotive, consumer electronics, and semiconductors is also contributing to the market growth. As these industries continue to evolve and adopt new technologies, the demand for precise and efficient measurement tools is expected to increase, further boosting the market growth. Overall, the global market for 3D laser profile measuring instruments is poised for significant growth in the coming years, driven by the increasing demand for precision and efficiency in various industries.

| Report Metric | Details |

| Report Name | 3D Laser Profile Measuring Instrument Market |

| Accounted market size in 2023 | US$ 182 million |

| Forecasted market size in 2030 | US$ 486 million |

| CAGR | 15.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KEYENCE, Cognex, Czlslaser, HIKROBOT, LMI Technologies, Micro-Epsilon, Teledyna DALSA, Vision Components, Qingbo Optoelectronics, SmartRay, Zebra Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |