What is Global Copolyester PCTG Material Market?

The Global Copolyester PCTG Material Market refers to the worldwide industry focused on the production, distribution, and utilization of PCTG (Polycyclohexylenedimethylene Terephthalate Glycol-modified) materials. PCTG is a type of copolyester known for its excellent clarity, toughness, and chemical resistance, making it a versatile material in various applications. This market encompasses a wide range of industries, including household products, cosmetics, home appliances, medical devices, and more. The demand for PCTG materials is driven by their superior properties compared to other plastics, such as better impact resistance and transparency. Additionally, PCTG is often chosen for its ease of processing and recyclability, aligning with the growing global emphasis on sustainable materials. The market is characterized by continuous innovation and development, with manufacturers constantly seeking to improve the performance and environmental footprint of PCTG materials. As industries increasingly adopt PCTG for its beneficial properties, the market is expected to expand, driven by both technological advancements and rising consumer awareness of sustainable products.

Injection Grade, Extrusion Grade, Blow Molding Grade in the Global Copolyester PCTG Material Market:

Injection Grade, Extrusion Grade, and Blow Molding Grade are three primary classifications within the Global Copolyester PCTG Material Market, each serving distinct applications based on their unique properties. Injection Grade PCTG is specifically designed for injection molding processes, where the material is melted and injected into molds to form various shapes and products. This grade is highly valued for its excellent flow characteristics, making it ideal for producing intricate and detailed components with high precision. Products made from Injection Grade PCTG include medical devices, cosmetic packaging, and small household items, where clarity, strength, and durability are crucial. Extrusion Grade PCTG, on the other hand, is tailored for extrusion processes, where the material is melted and forced through a die to create continuous shapes such as sheets, films, and profiles. This grade is known for its superior melt strength and stability, which are essential for maintaining consistent quality during the extrusion process. Extrusion Grade PCTG is commonly used in the production of packaging materials, such as blister packs and clamshells, as well as in the manufacturing of various industrial and consumer goods that require high transparency and impact resistance. Blow Molding Grade PCTG is designed for blow molding applications, where the material is melted and formed into hollow shapes by inflating it within a mold. This grade is particularly suitable for creating bottles, containers, and other hollow products that require excellent clarity, toughness, and chemical resistance. Blow Molding Grade PCTG is widely used in the beverage, cosmetic, and pharmaceutical industries, where the quality and safety of the packaging are paramount. The material's ability to withstand high impact and its resistance to various chemicals make it an ideal choice for these applications. Each of these grades of PCTG material offers unique advantages that cater to specific manufacturing processes and end-use applications. The versatility of PCTG, combined with its superior properties, makes it a preferred choice across various industries. Manufacturers continue to innovate and develop new formulations of PCTG to meet the evolving demands of the market, ensuring that the material remains at the forefront of modern manufacturing. As a result, the Global Copolyester PCTG Material Market is poised for continued growth, driven by the diverse applications and the ongoing advancements in material science.

Household Products, Cosmetic, Home Appliances, Medical, Other in the Global Copolyester PCTG Material Market:

The usage of Global Copolyester PCTG Material Market spans across several key areas, including household products, cosmetics, home appliances, medical devices, and other applications. In the realm of household products, PCTG is favored for its durability, clarity, and safety. Items such as storage containers, kitchen utensils, and various home organization products benefit from PCTG's impact resistance and transparency, making them both functional and aesthetically pleasing. The material's non-toxic nature also ensures that it is safe for use in products that come into contact with food and beverages. In the cosmetics industry, PCTG is widely used for packaging solutions due to its excellent clarity and chemical resistance. Cosmetic containers, such as bottles, jars, and compacts, made from PCTG, not only protect the product from external contaminants but also enhance the visual appeal of the packaging. The material's ability to be easily molded into intricate shapes allows for innovative and attractive designs, which are crucial in the highly competitive cosmetics market. Additionally, PCTG's resistance to oils and solvents ensures that the packaging remains intact and does not react with the cosmetic products. Home appliances also benefit from the use of PCTG materials, particularly in components that require high strength and transparency. Parts such as blender jars, food processor bowls, and other clear components are often made from PCTG due to its ability to withstand repeated use and cleaning without losing clarity or becoming brittle. The material's toughness and resistance to impact make it ideal for appliances that are subject to frequent handling and potential drops. In the medical field, PCTG is utilized for a variety of applications, including medical device housings, surgical instruments, and pharmaceutical packaging. The material's biocompatibility, clarity, and sterilizability make it suitable for use in environments where hygiene and safety are paramount. Medical devices made from PCTG can be easily sterilized without degrading the material, ensuring that they remain safe for repeated use. Additionally, PCTG's resistance to chemicals and impact makes it a reliable choice for packaging sensitive pharmaceutical products. Beyond these primary areas, PCTG is also used in other applications such as sports equipment, toys, and electronic components. The material's versatility and superior properties make it suitable for a wide range of products that require durability, clarity, and safety. As industries continue to seek materials that offer both performance and sustainability, PCTG remains a popular choice due to its recyclability and lower environmental impact compared to other plastics. The ongoing development and innovation in PCTG formulations further expand its potential applications, ensuring that it remains a key material in various industries.

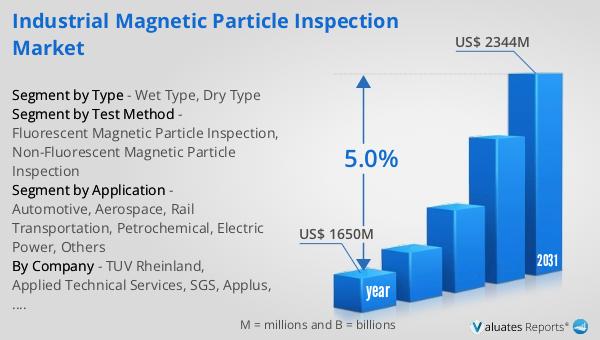

Global Copolyester PCTG Material Market Outlook:

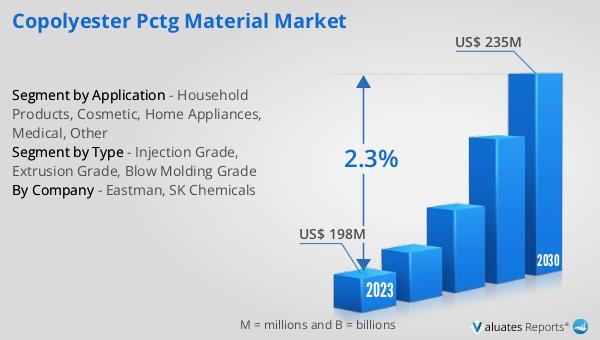

The global Copolyester PCTG Material market was valued at US$ 198 million in 2023 and is anticipated to reach US$ 235 million by 2030, witnessing a CAGR of 2.3% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the PCTG material market over the next several years. The increase in market value reflects the rising demand for PCTG materials across various industries due to their superior properties and versatility. As manufacturers and consumers alike become more aware of the benefits of PCTG, including its clarity, toughness, and chemical resistance, the market is expected to expand further. The projected growth rate of 2.3% CAGR suggests a consistent and sustainable increase in the adoption of PCTG materials, driven by ongoing innovations and the development of new applications. This positive market outlook underscores the importance of PCTG in modern manufacturing and its potential to meet the evolving needs of various industries.

| Report Metric | Details |

| Report Name | Copolyester PCTG Material Market |

| Accounted market size in 2023 | US$ 198 million |

| Forecasted market size in 2030 | US$ 235 million |

| CAGR | 2.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Eastman, SK Chemicals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |